|

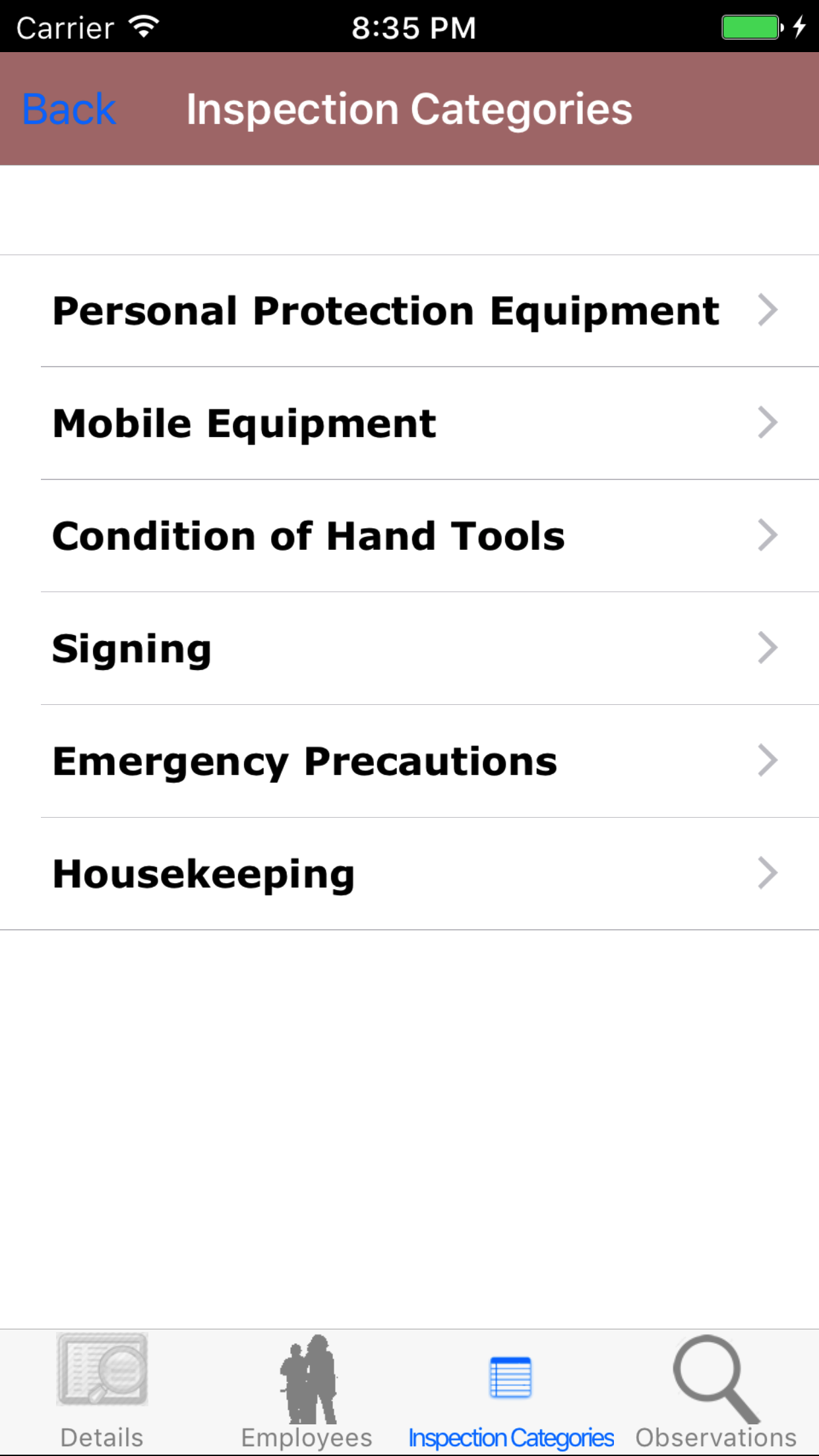

The safety inspection section allows a user to input the results of safety inspections performed on job sites for a specific work order. A safety inspection

is intended to look at the performance of field staffs safety preparedness and organization. The vehicle inspection can be setup to be done on a

daily, weekly or monthly basis. The vehicle inspection is set up in a number of

sections; basic information, checklists of tasks to inspect, and observations.

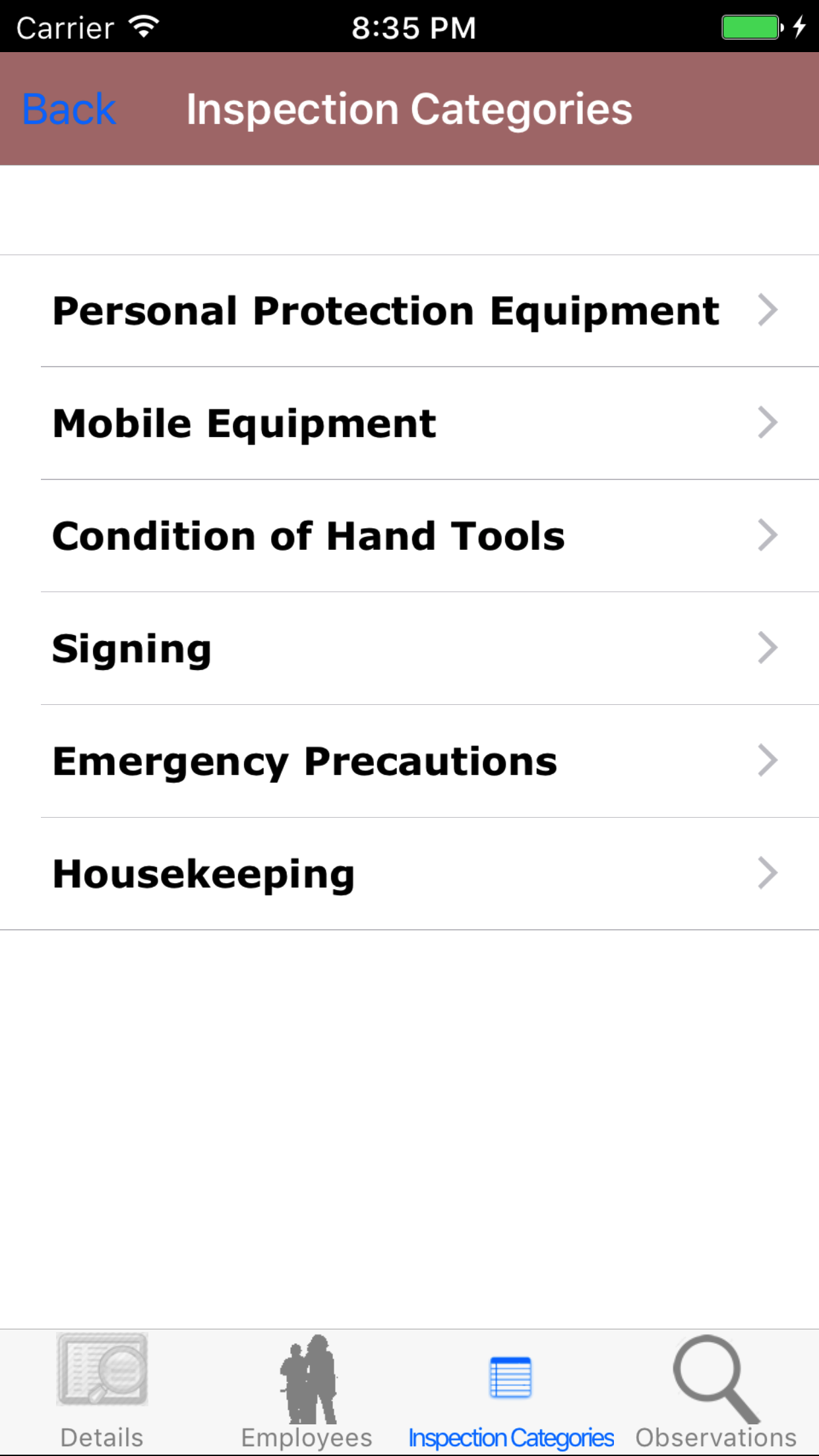

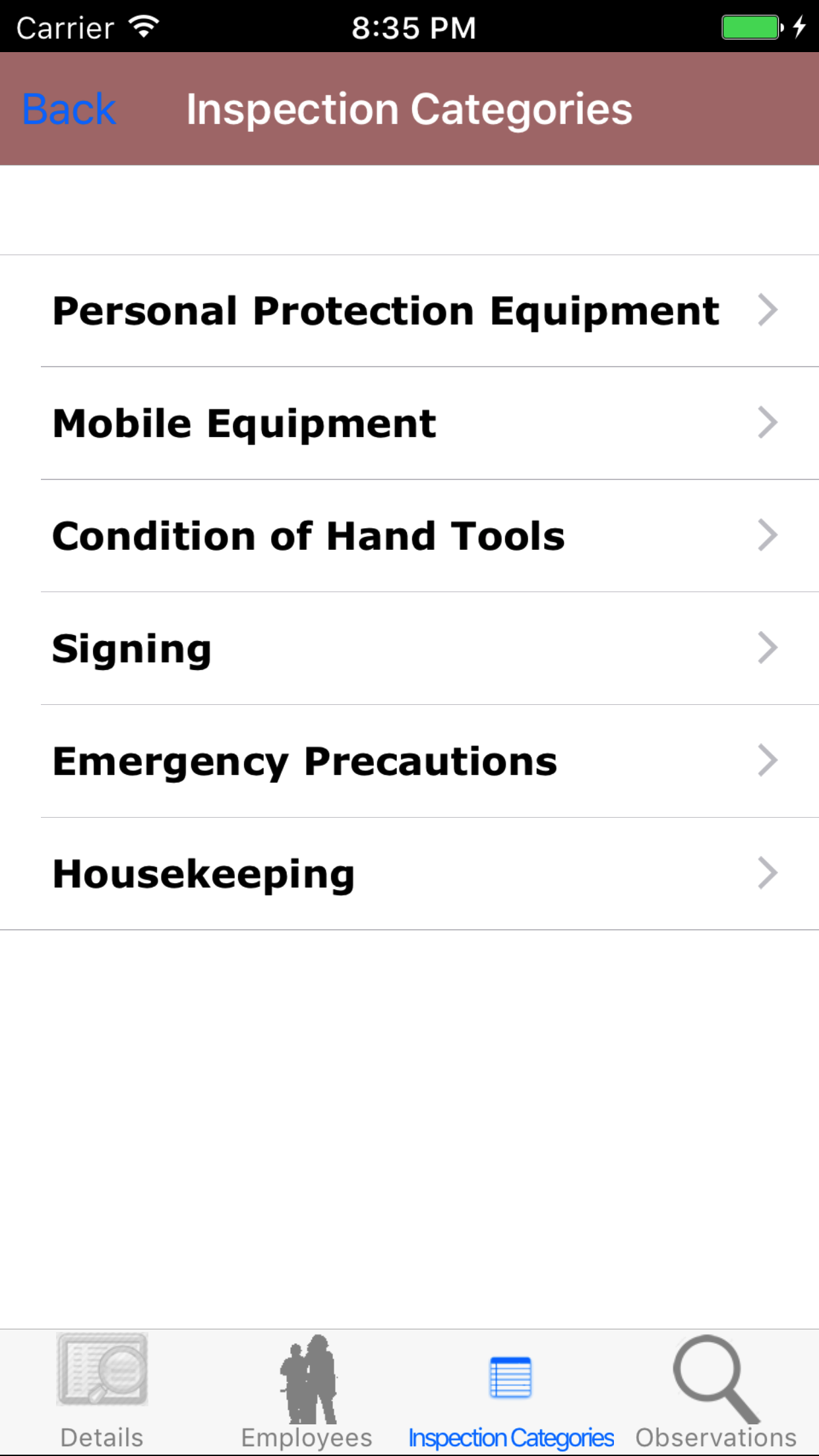

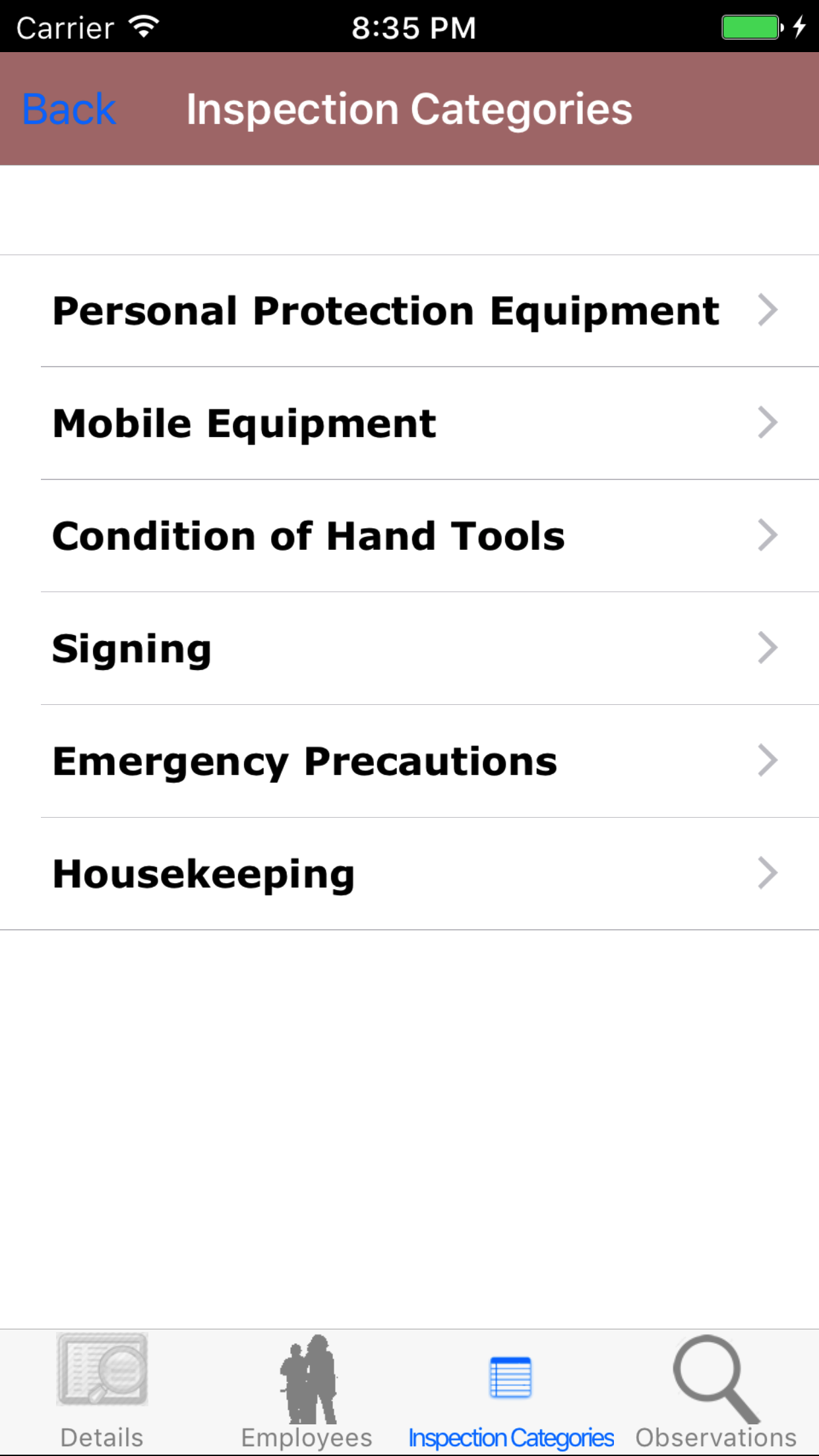

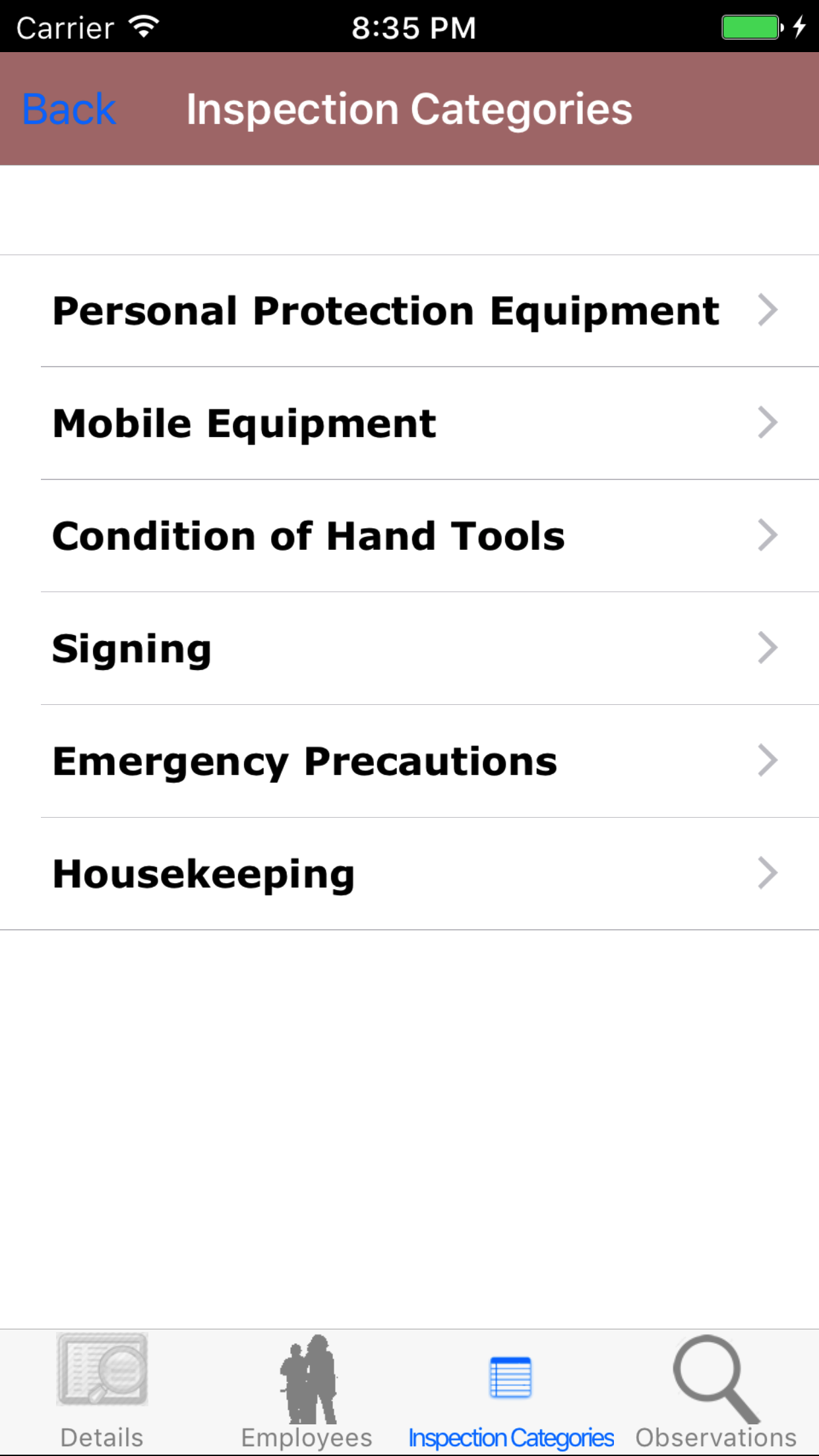

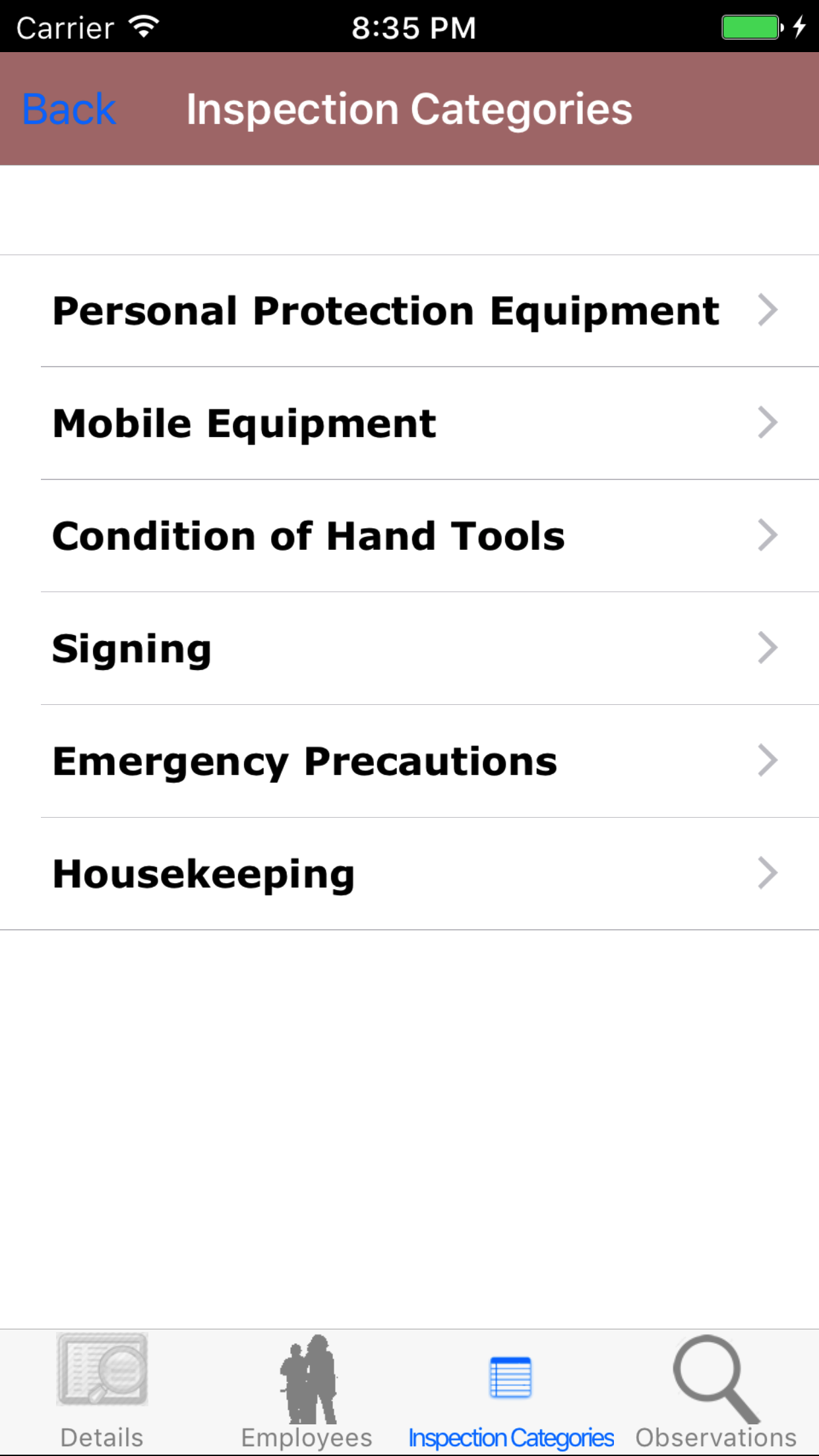

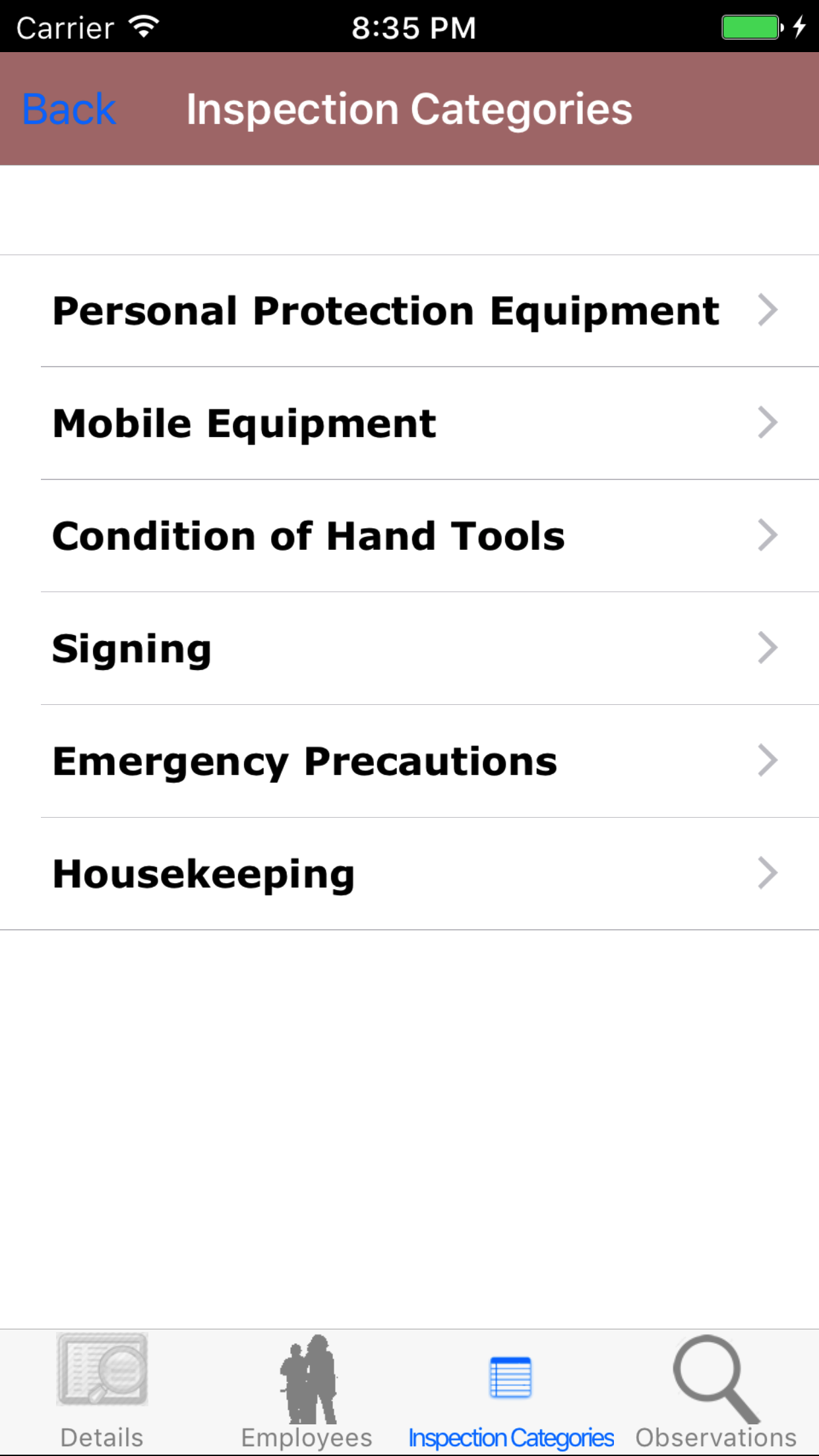

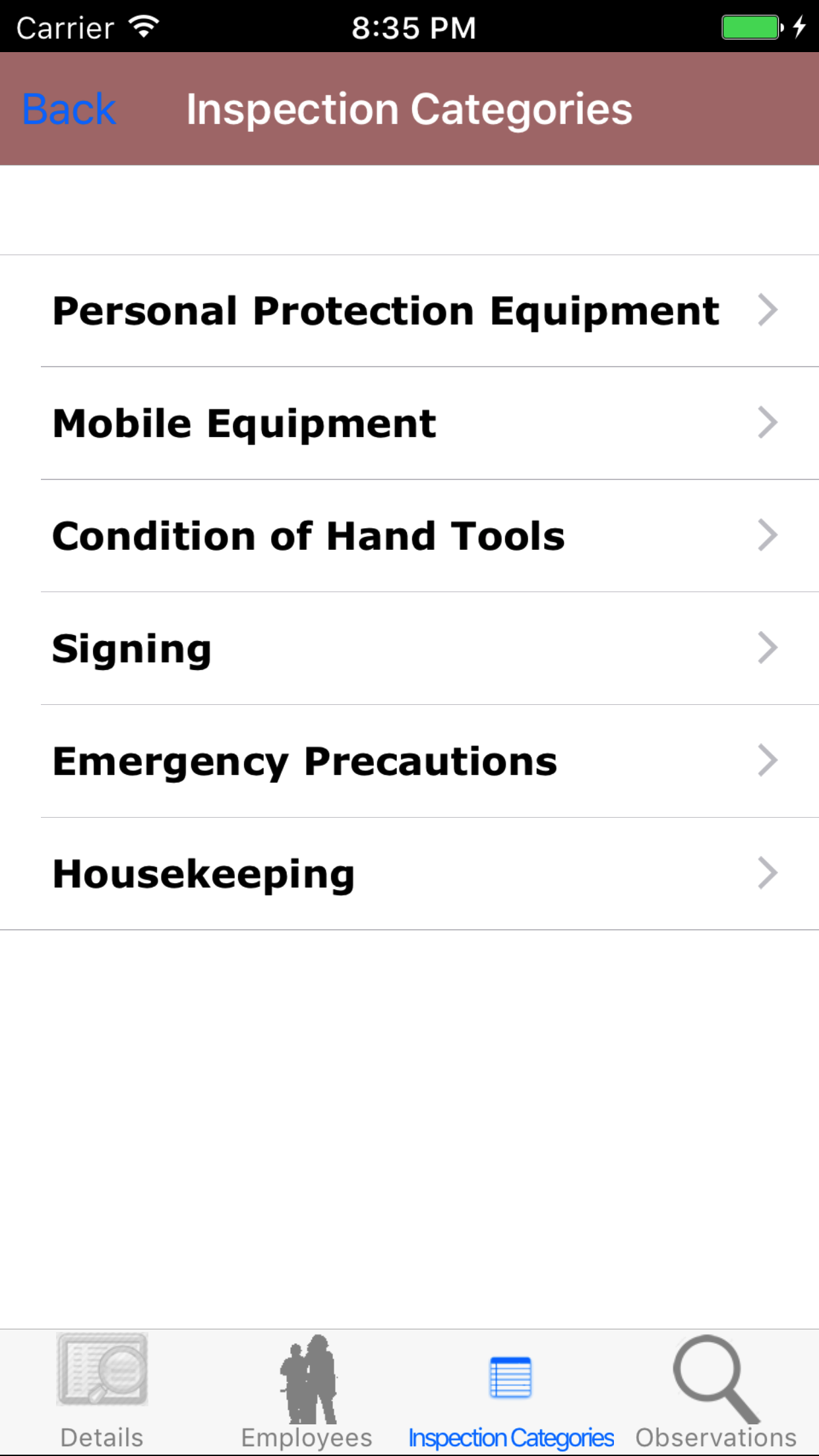

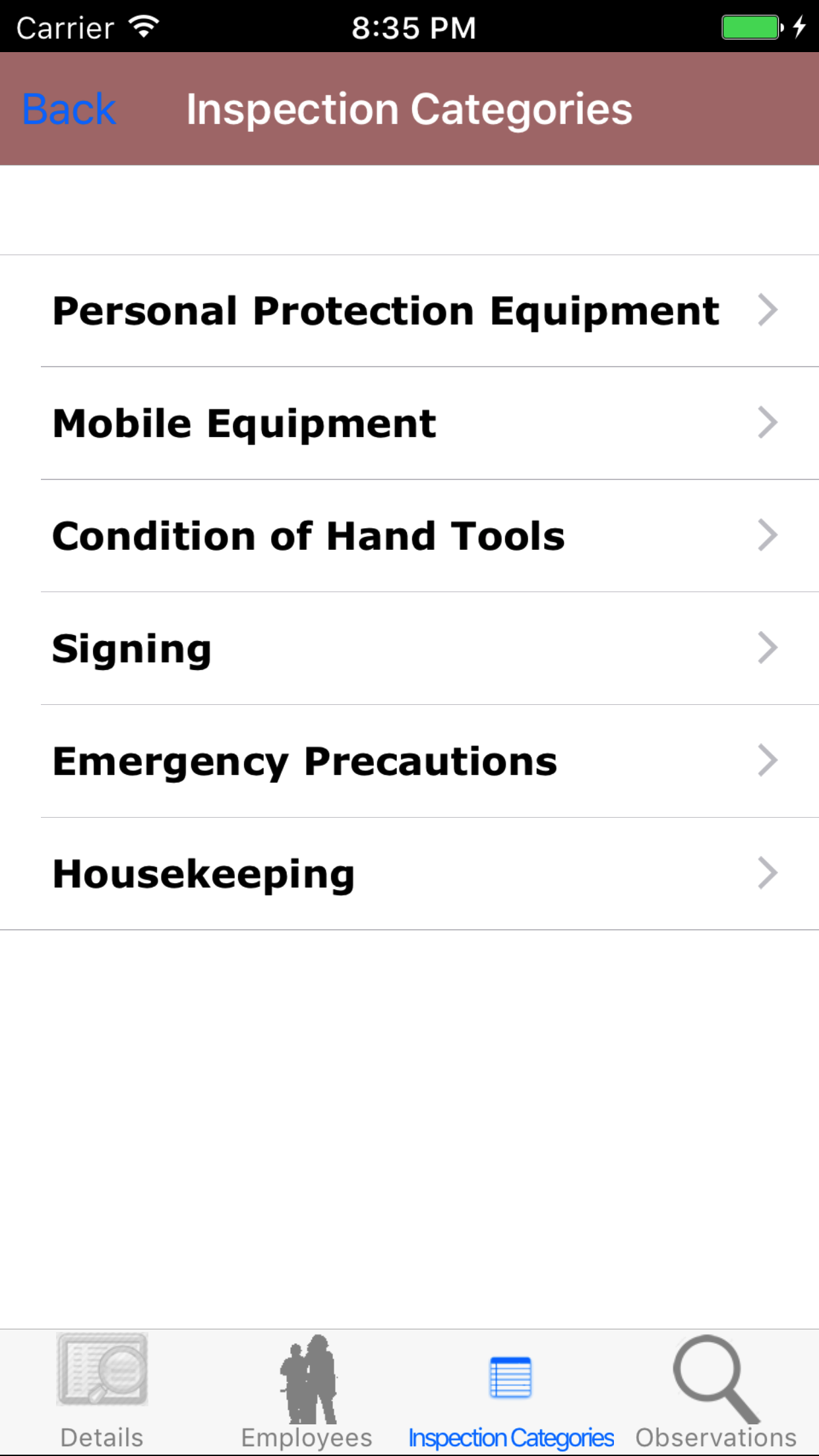

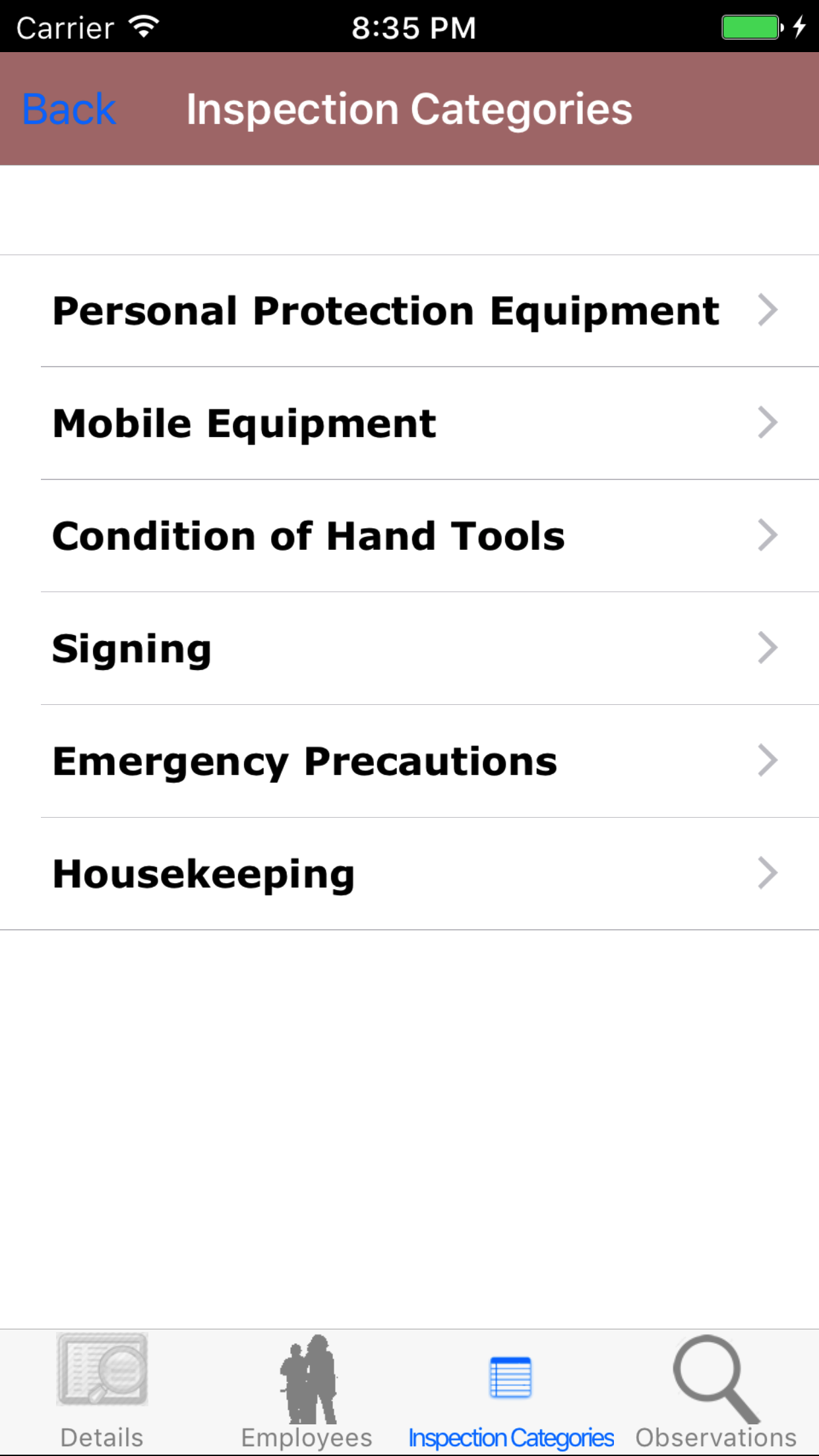

The checklists are configured and maintained by company staff, to match up with companies safety concerns and field of work. The checklist categories include

- Personal Protective Equipment

- Mobile Equipment

- Condition of Hand Tools

- Signing

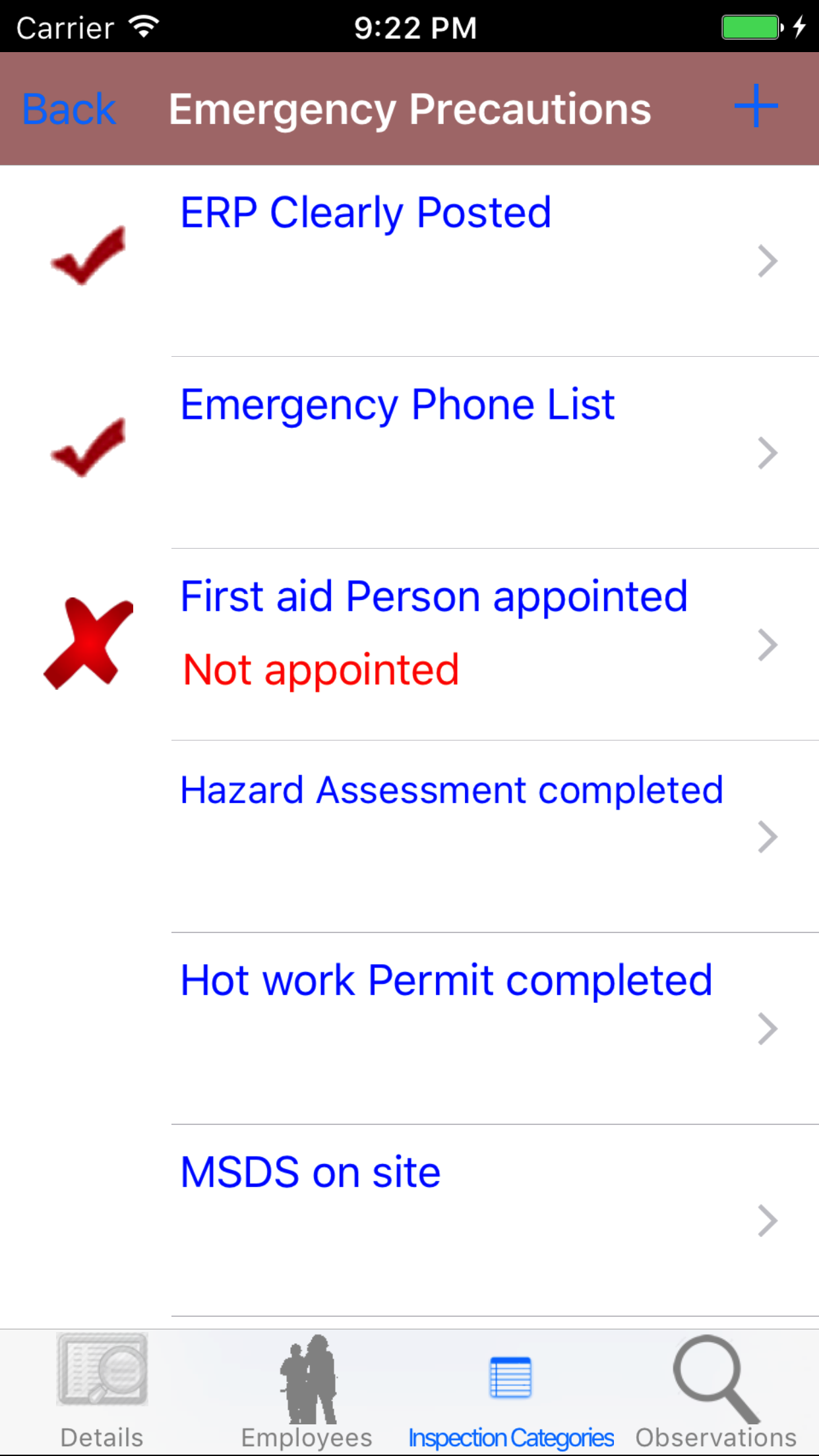

- Emergency Precautions

- Housekeeping

When Checklist items are marked as requiring attention, observation records are created in the Observation section of the safety inspection. Field Staff can add other

observations directly from the Observation section of the safety inspection.

Once a observation has been created, a follow up for the observation should be added to spell out how the problem will be solved

Configuring Safety Net Safety Inspection task checklists

On a Safety Inspection there are 6 sections of lists that companies must maintain. These six sections make up the

majority of the Safety inspection. Companies can choose tasks from the list of Safety Net’s default safety inspection tasks or add their own tasks to tailor their inspection to their companies needs.

For more information about company safety inspection tasks lists check out the Safety Inspection Tasks lists section of the manual.

Configuring how often safety inspections should occur

How often safety inspections must occur is a function of your companies policy regarding safety inspections. To configure Safety Net for how often vehicle inspection should occur can be configured in the company safety settings.

Management, Office Staff and Safety Officers can edit how often safety inspections should occur in the Company section when they edit the Company Safety settings.

For more information about company safety setting check out the Edit Company Safety Settings in the Company section of the manual.

|

|

|

1.Add Safety Inspection |

Steps

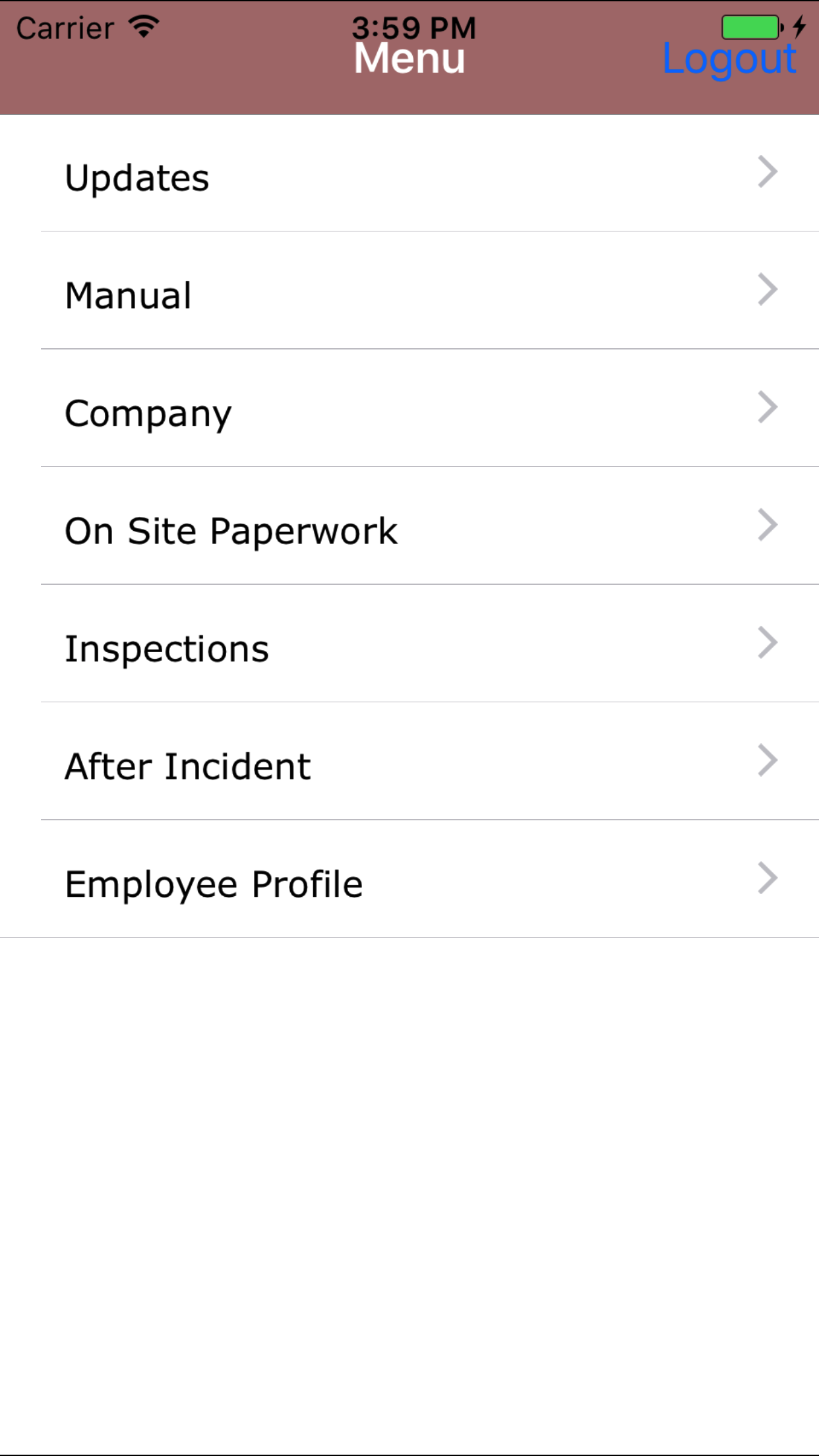

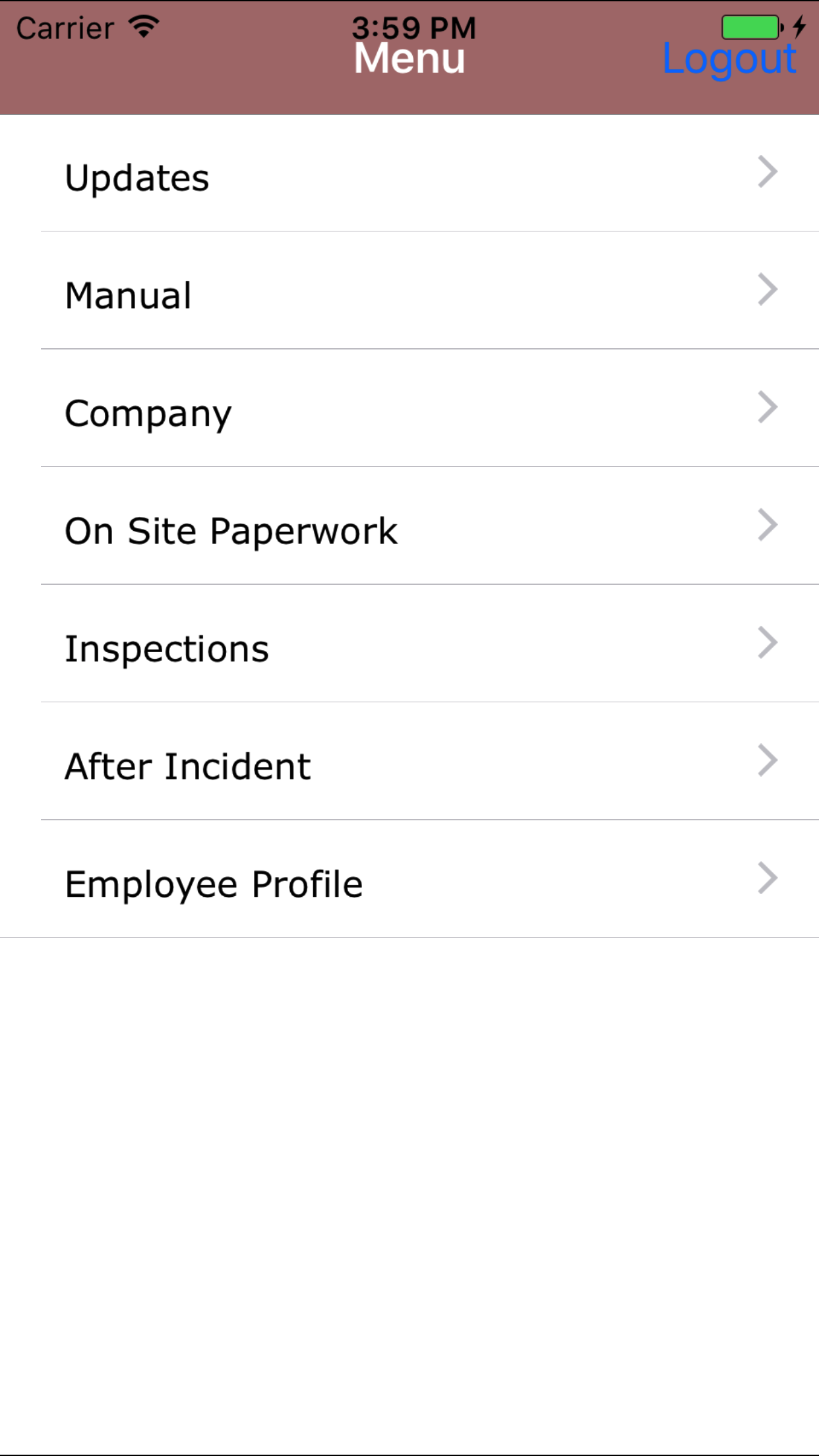

- From the Main Menu screen, tap the Inspection button.

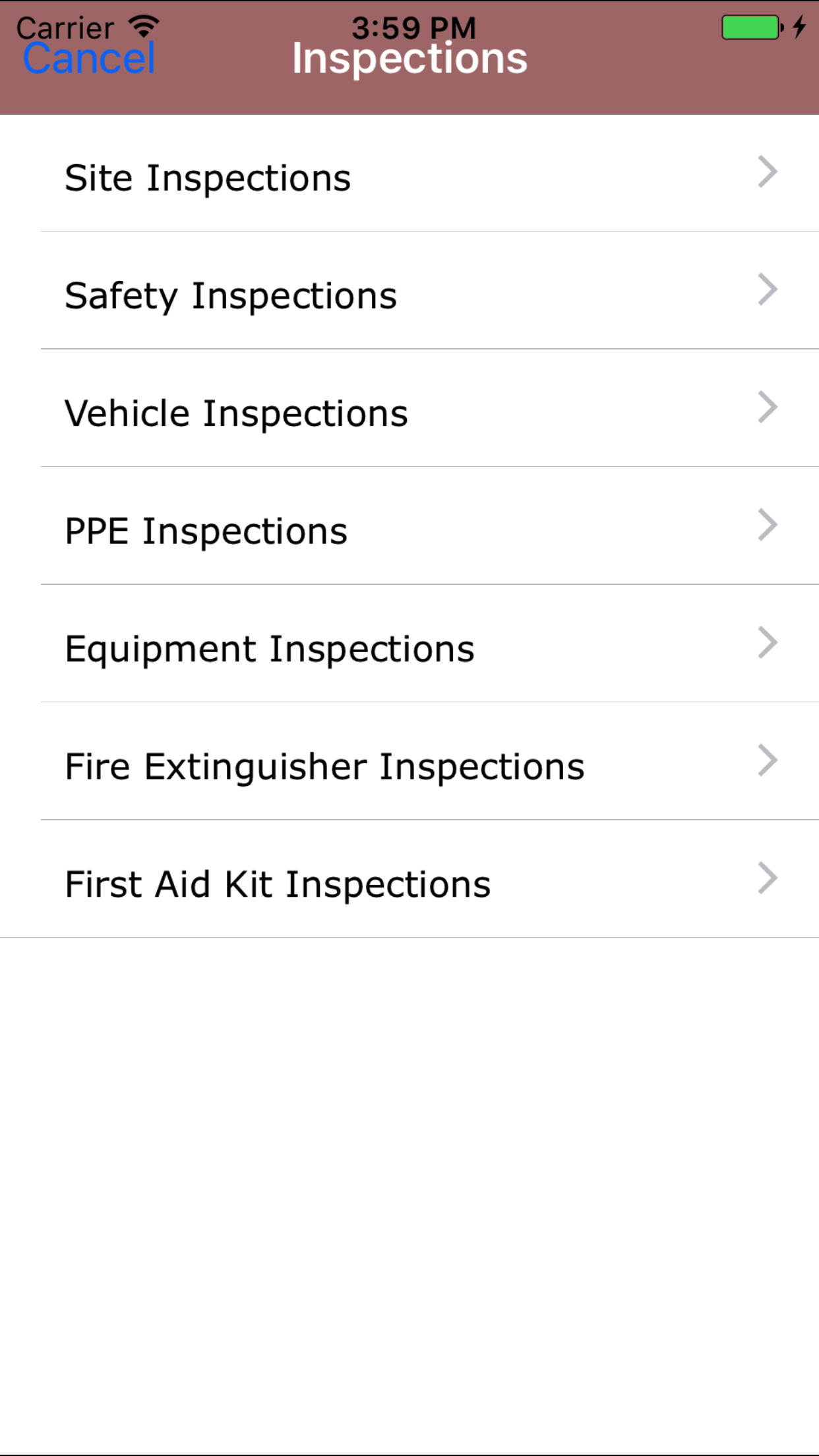

- Then tap on the Safety Inspection button.

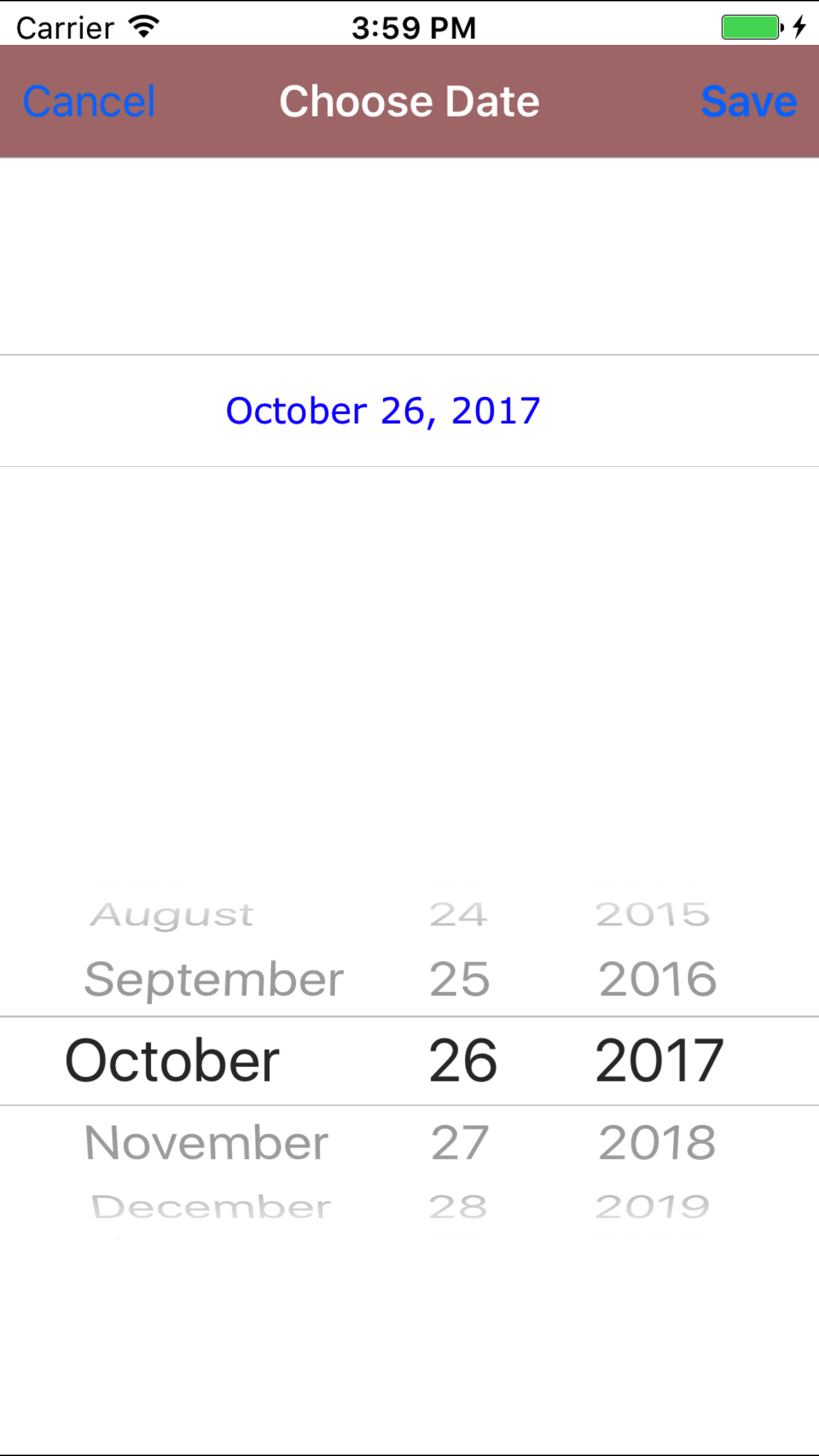

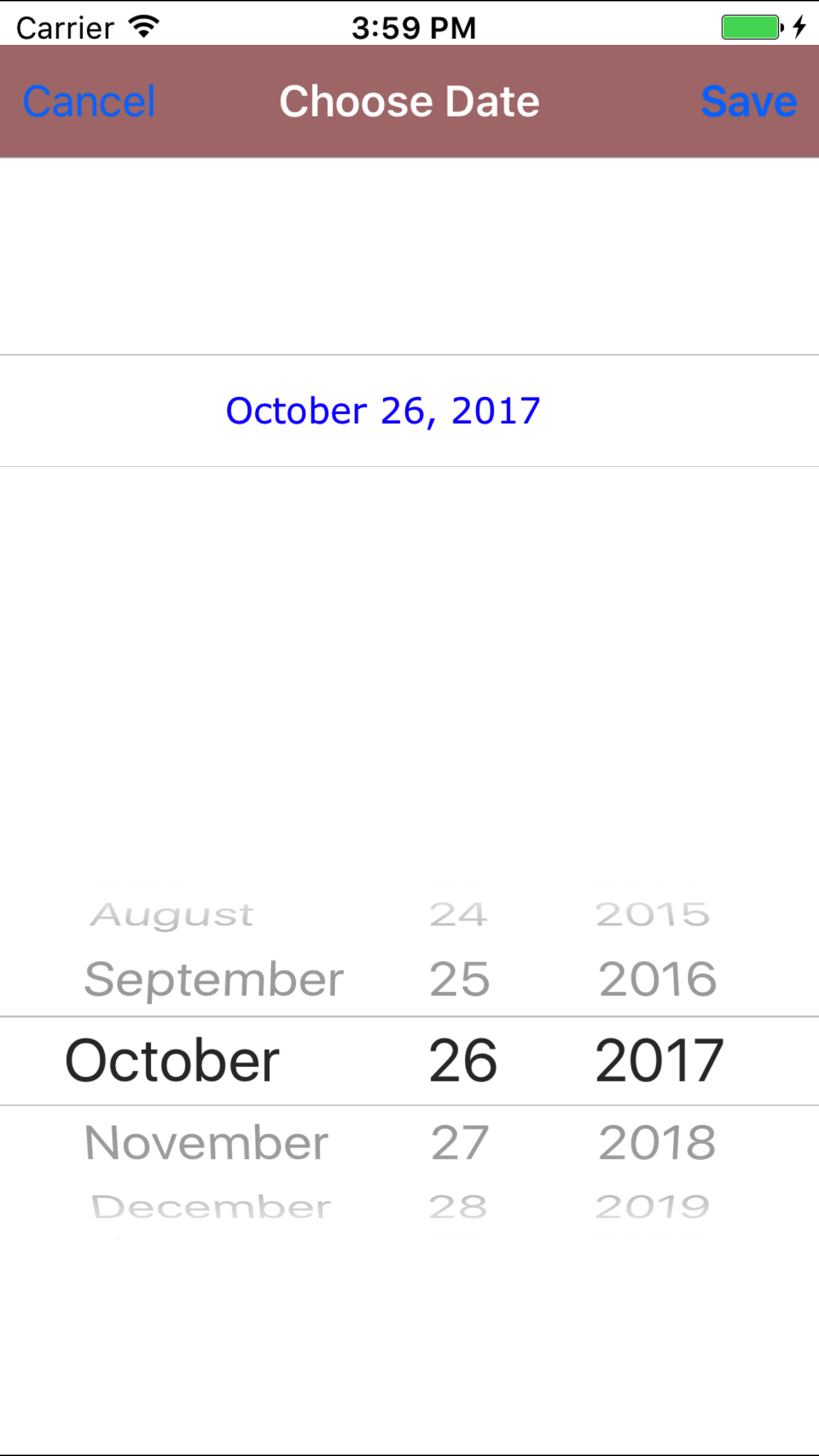

- Date: The date field allow field staff to choose the date and time the safety inspection occurs.

- Tap the Date field to open the Choose Date screen.

- Scroll the date wheel on the far left of the screen until the desired date is highlighted.

- Return to the Add Safety Inspection screen by either tapping Save in the top right corner to select the highlighted date or tapping Cancel in the top left corner to leave the Date: field unchanged.

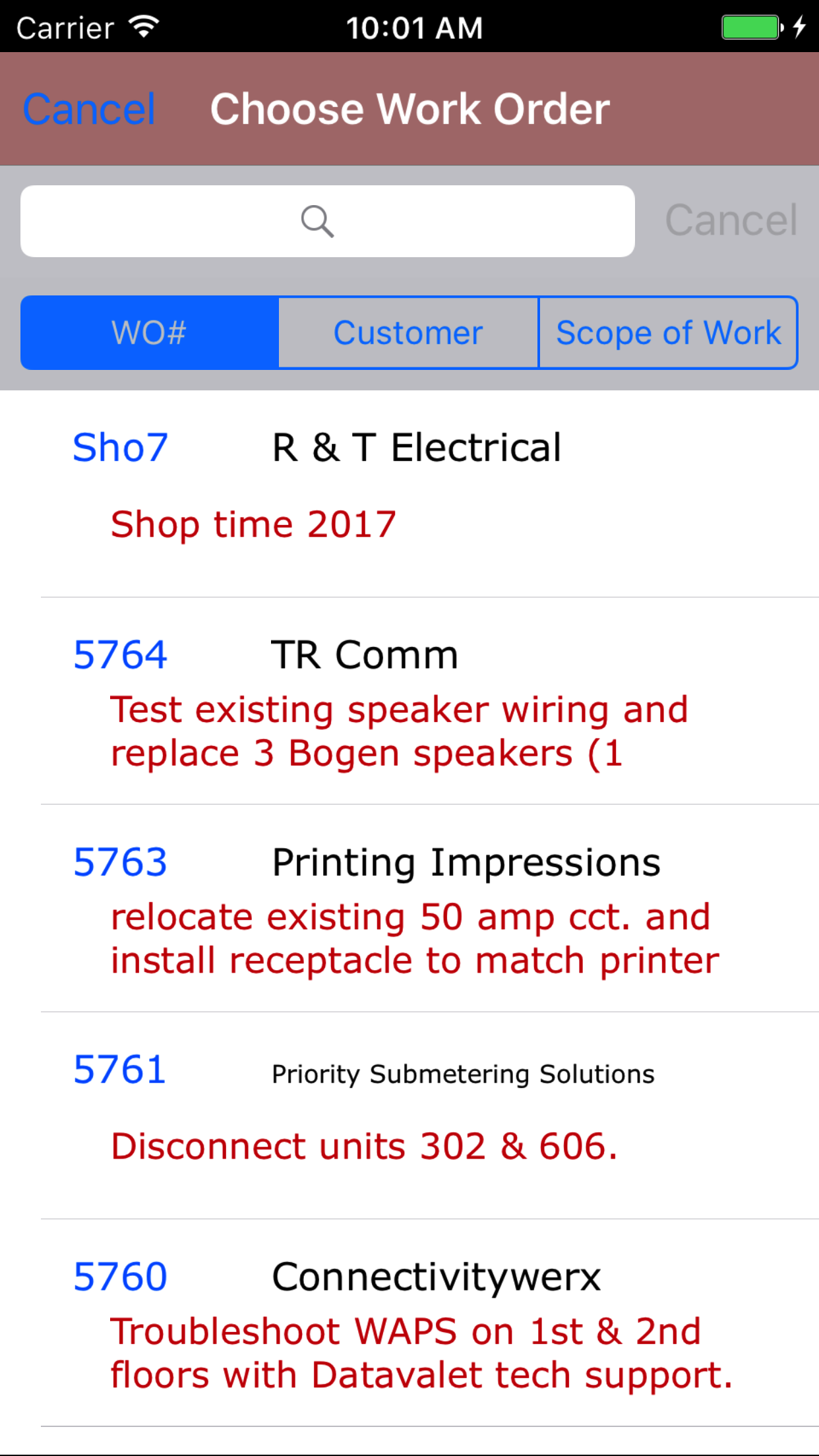

- Tap the Work Order # field to open the Choose Work Order screen.

Work orders are listed in descending order with the work order number in blue text,

the customer name in black text, and the scope of work in red text.

Note: New work orders are not automatically added to the list when they are created, so it may be necessary to

update the list click here to view information about updating for the desired work order to be included in the list.

- Scroll the list of work orders until the desired work order is displayed on the screen.

- Tap the desired work order to select it or tap Back in the top left corner to leave the Work Order # field unchanged and return to the Add Safety Inspection screen.

- Return to the Add Safety Inspection screen by either tapping Save in the top right corner to select the highlighted work order or tapping Cancel in the top left corner to leave the Work Order field unchanged.

- Tap the + icon in the top right corner to add the Safety Inspection.

- A pop-up message that reads Safety Inspection Added indicates that the Safety Inspection is ready to have details to be entered and checklists of inspection tasks checked off.

|

|

| Step 1 |

|

|

| Step 2 |

|

|

|

|

2.Look Up Open Safety Inspection |

|

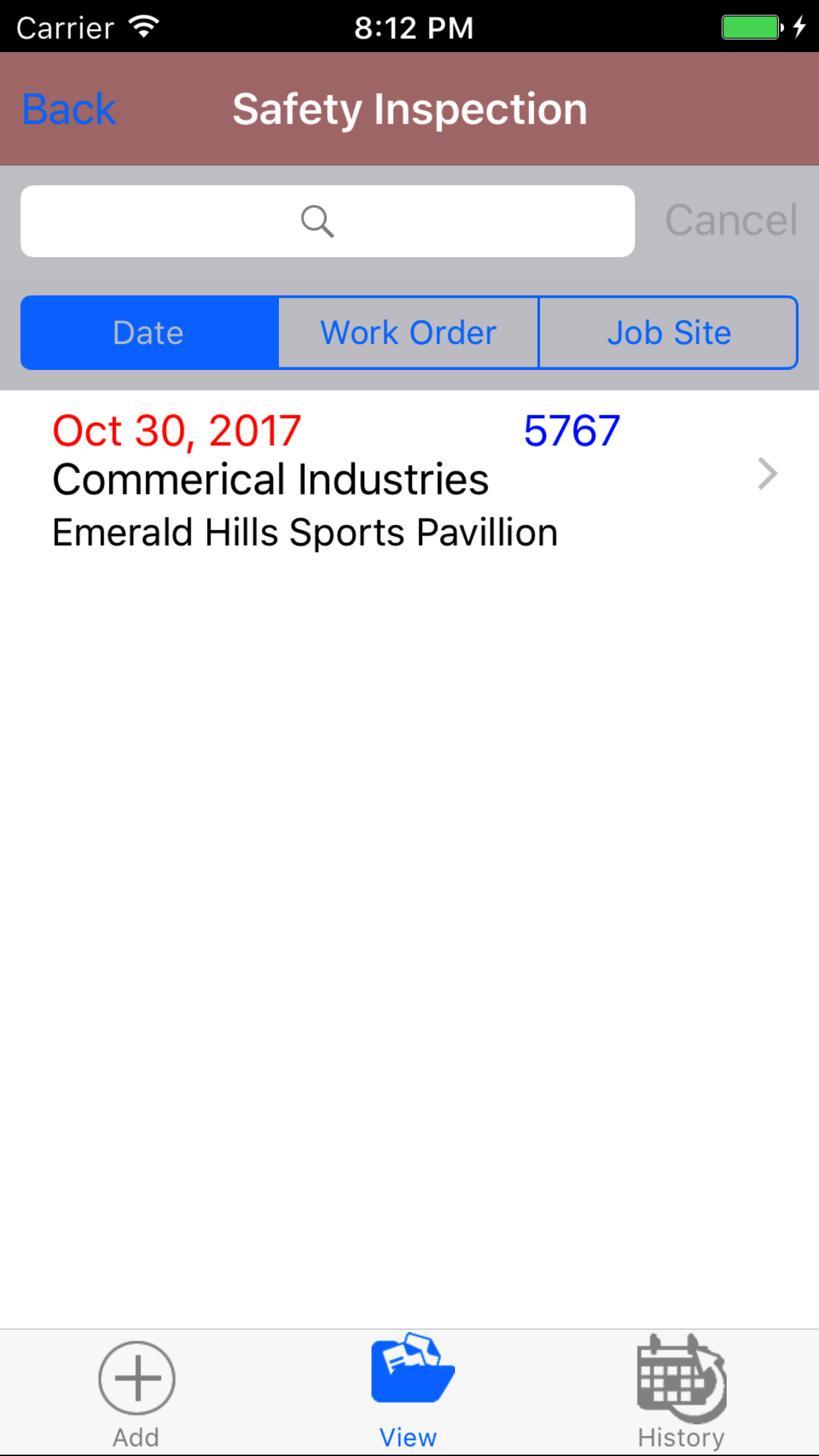

Once in the Safety Inspection section

Steps

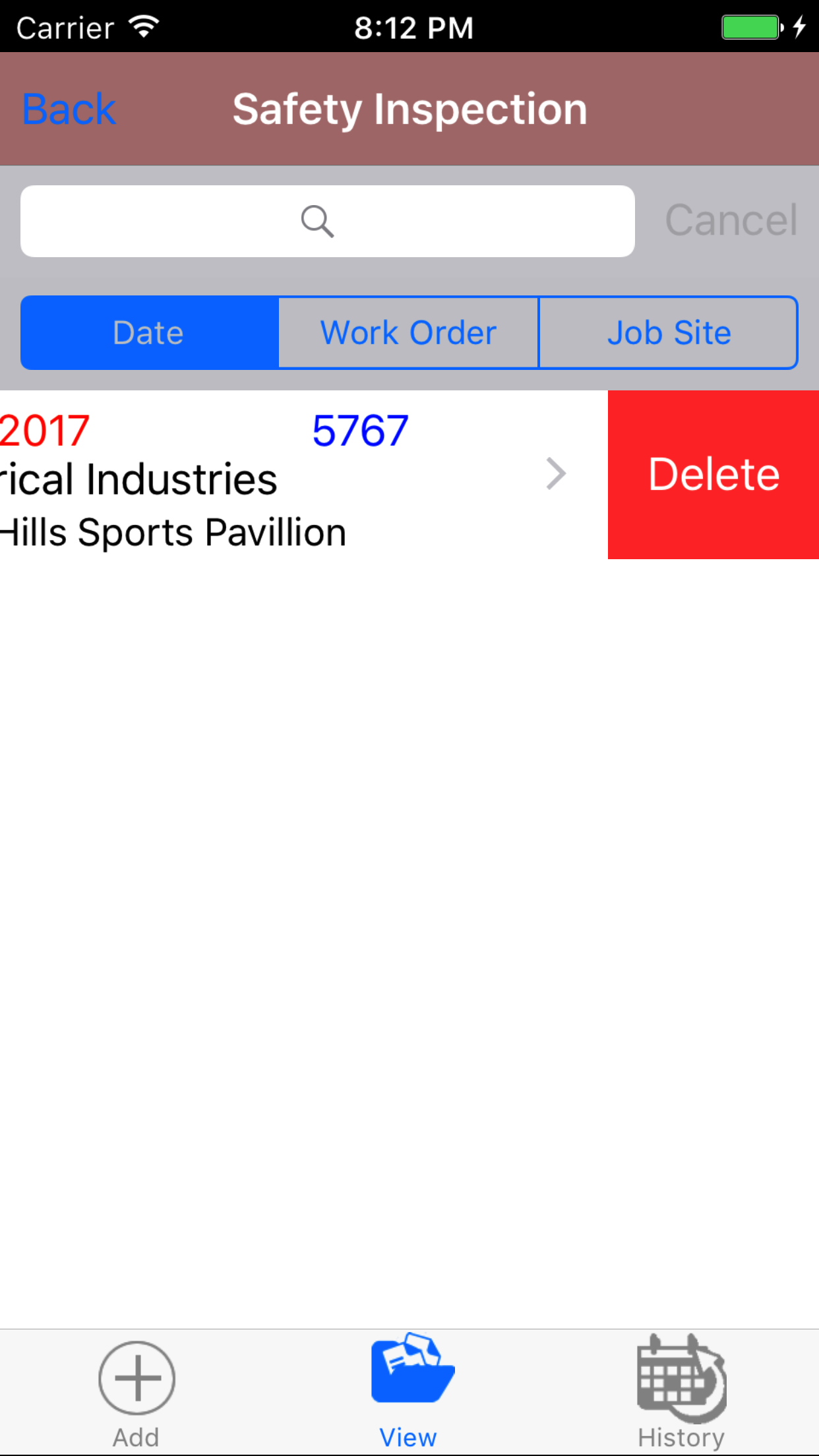

- Tap the second tab on the menu, the Safety Inspection view.

- Scroll the list of Safety Inspections until the desired Safety Inspection is displayed on the screen.

Listing the safety inspection date in red text, the work order number in blue text

and the the customer name and job site in black text.

- Tap on the Safety Inspection you would like to view. This loads the safety inspection edit screen.

|

|

| Steps 1-2 |

|

|

3.Edit Safety Inspection |

|

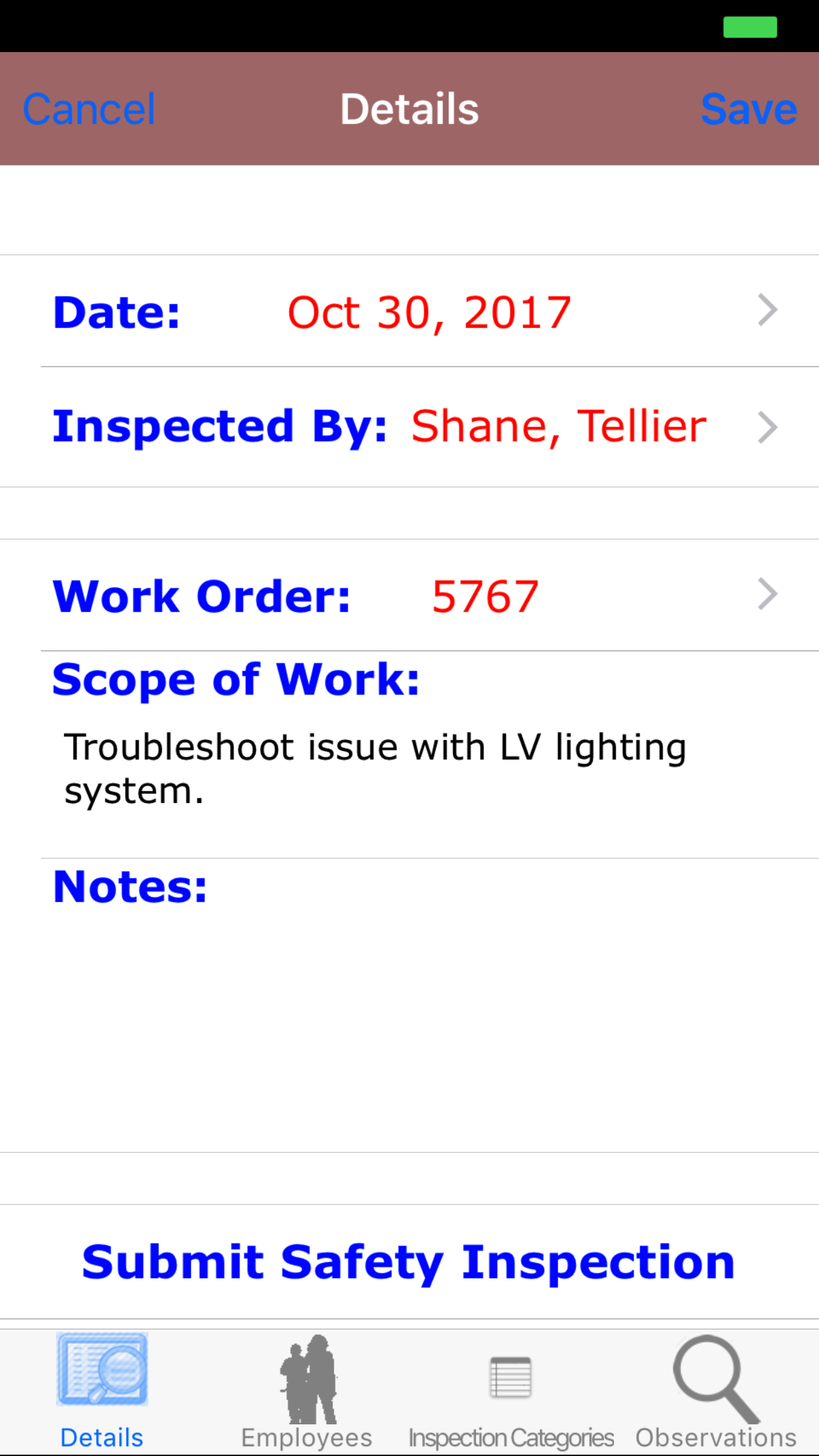

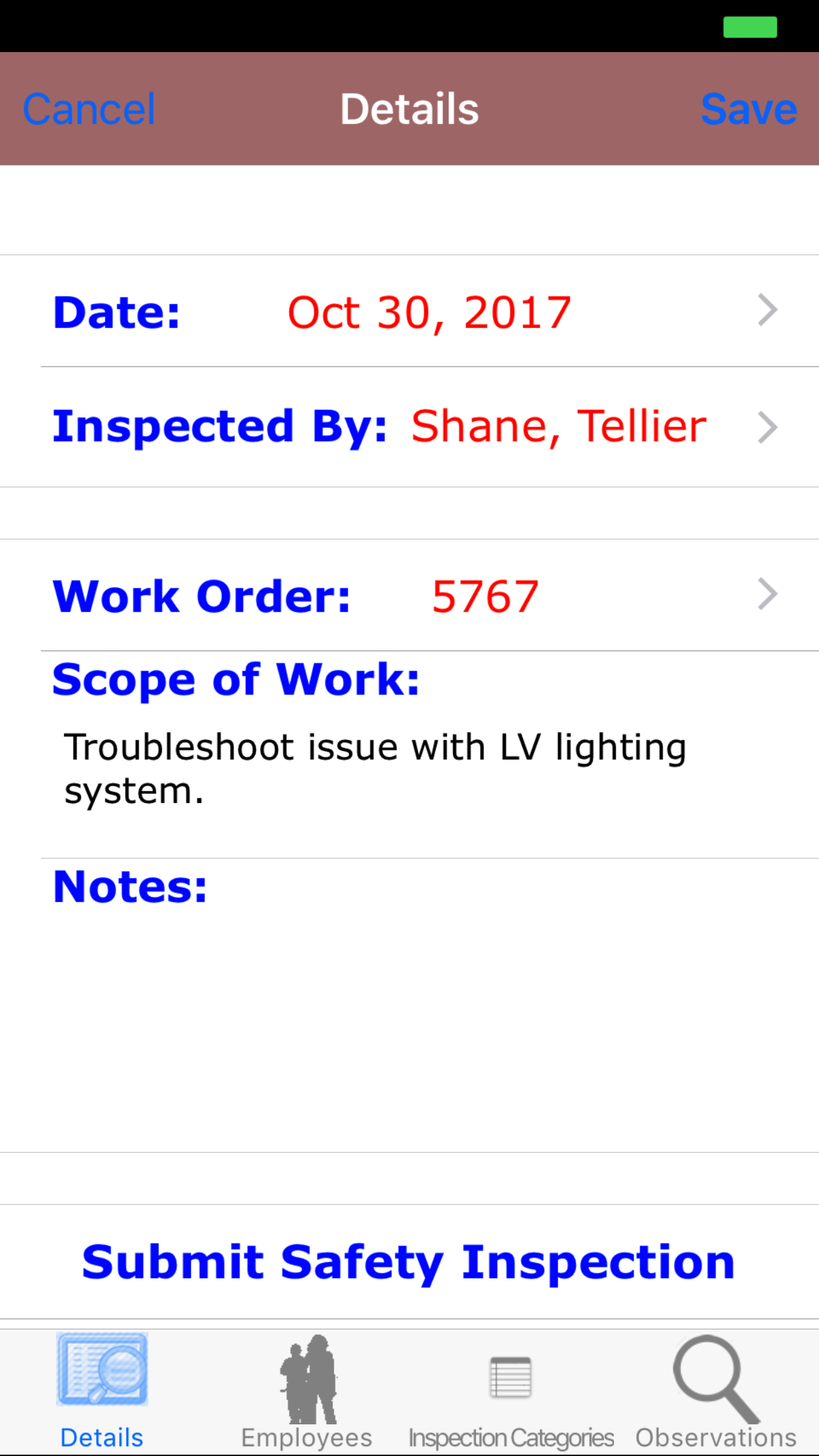

The first step in completing a Safety Inspection is completing the details of the inspection; including date, setting the employee whom inspected the job site,

work order number, scope of work and notes.

Once on the Safety Inspection you would like to Edit, on the details tab.

Steps

- Date: The date field allow field staff to choose the date and time the safety inspection occurs.

- Tap the Date field to open the Choose Date screen.

- Scroll the date wheel on the far left of the screen until the desired date is highlighted.

- Return to the Edit Safety Inspection screen by either tapping Save in the top right corner to select the highlighted date or tapping Cancel in the top left corner to leave the Date: field unchanged.

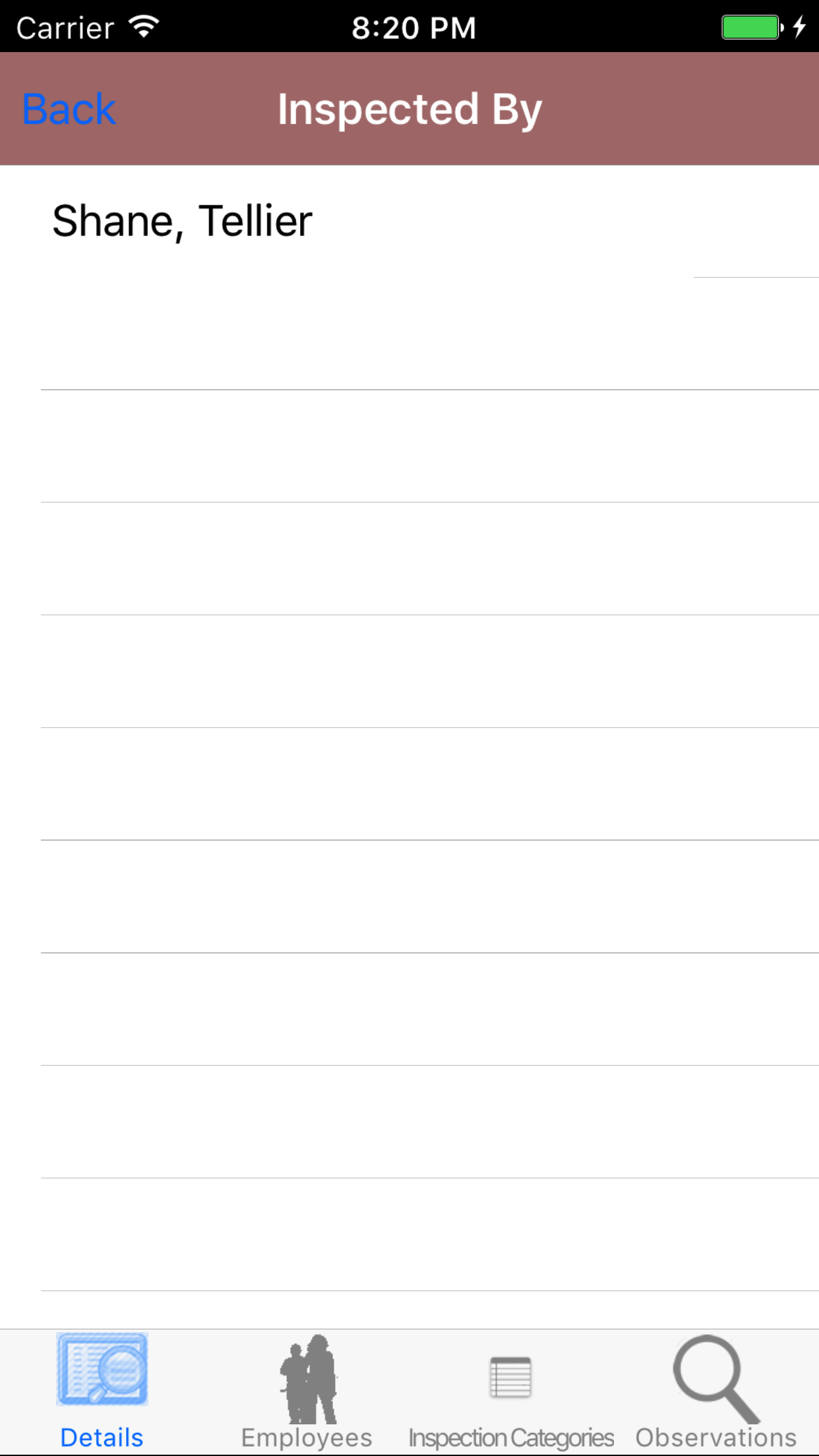

- Inspected By: The inspected by field initially displays the name of the person who added the Hazard Assessment and should be updated to indicate the employee on site who is responsible for safety.

- Tap the Inspected By: field to open the Employees screen.

Employees are listed in the order they were added to the Safety Inspection.

- Tap the desired work order to select it or tap Back in the top left corner to leave the Work Order # field unchanged and return to the Edit Safety Inspection screen.

- Return to the Edit Safety Inspection screen by either tapping Save in the top right corner to select the highlighted date or tapping Cancel in the top left corner to leave the Employee field unchanged.

- Tap the Work Order # field to open the Choose Work Order screen.

Work orders are listed in descending order with the work order number in blue text,

the customer name in black text, and the scope of work in red text.

Note: New work orders are not automatically added to the list when they are created, so it may be necessary to update the list click here to view information about updating for the desired work order to be included in the list.

- Scroll the list of work orders until the desired work order is displayed on the screen.

- Tap the desired work order to select it or tap Back in the top left corner to leave the Work Order # field unchanged and return to the Add Safety Inspection screen.

- Return to the Edit Safety Inspection screen by either tapping Save in the top right corner to select the highlighted work order or tapping Cancel in the top left corner to leave the Work Order field unchanged.

- Scope of Work: The Scope of Work field initially displays the scope of work from the work order and, therefore, may need to be refined to reflect the scope of work for the day/shift. The character limit of this field is 250.

- Notes: The Notes field allows field staff to enter any notes or comments about the safety inspection. The character limit of the field is 500.

- Tap Save in the top right corner to save any changes to the Safety Inspection Details.

- A pop-up message that reads Safety Inspection Details have been Saved indicates that the safety inspection details have been saved.

|

|

|

| Step 1 |

|

|

| Step 2 |

|

|

| Step 2 |

|

|

| Steps 3-6 |

|

|

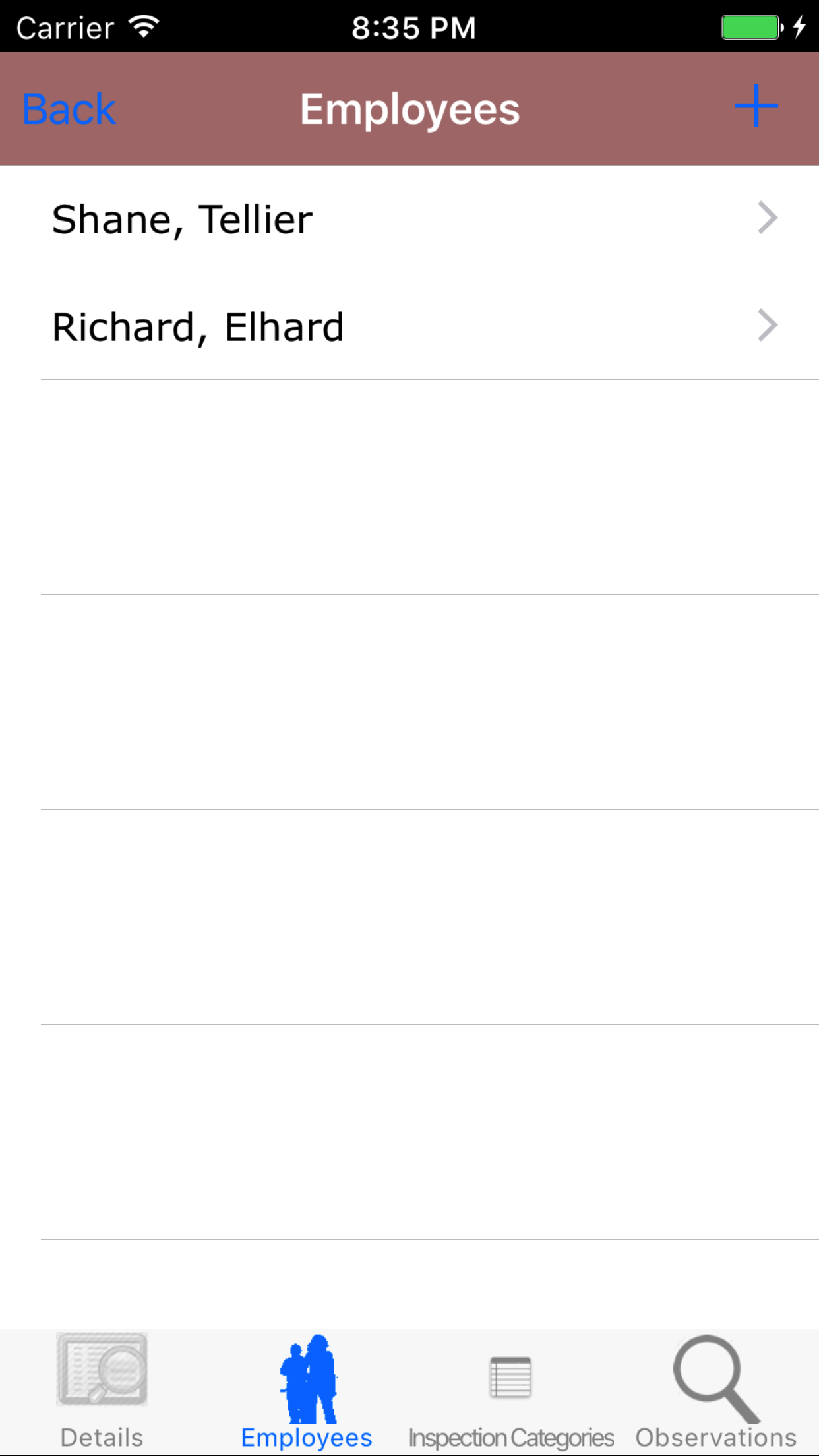

4.Add Employee to Safety Inspection |

|

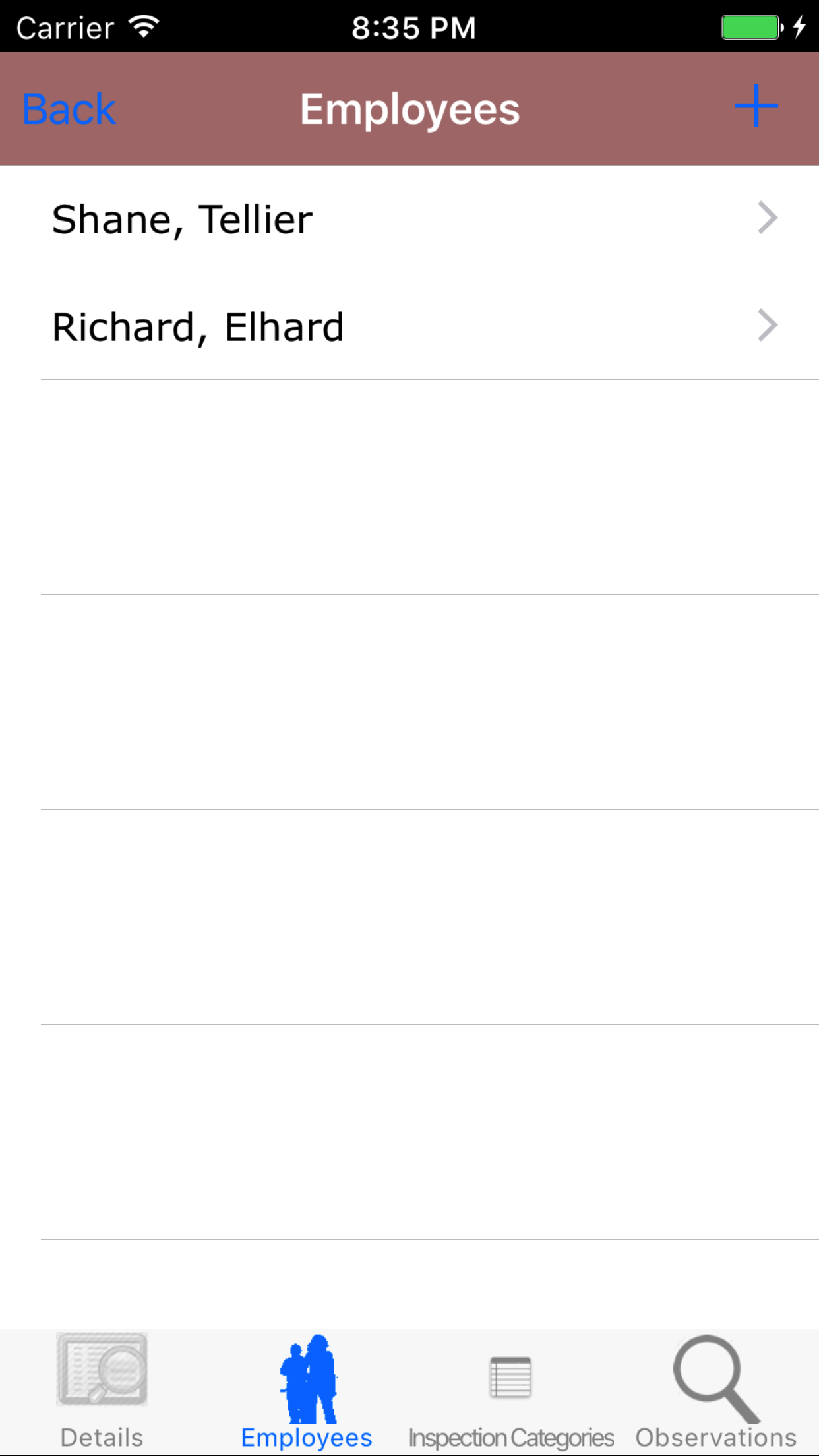

Adding employees to the Safety Inspection is crucial to reporting accurately. Adding other field staff to the safety inspection allows a group of

workers to share and complete a safety inspection as a group. Once a safety inspection is submitted all employee's added to the safety inspection will have access to the safety inspection.

Here are the steps on how to do it:

Once on the Safety Inspection you would like to Edit

Steps

- Tap the Employees icon at the bottom of the screen to open the Employees screen.

- Tap the + icon in the top right corner to open the Employees list or tap Employees in the top left corner to return to the Employees screen.

Employees are listed in descending order of last name.

- Scroll the list of employees until the desired employee is displayed on the screen.

- If the desired employee is in the list, tap the employee to add them to the Hazard Assessment.

A pop-up message that reads Employee Added indicates that the employee is now listed on the Hazard Assessment Employees screen.

- If the desired employee is not in the list, tap Add Outside Employee in the top left corner of the screen to open the New Employee screen.

- First Name: The First Name field should indicate the legal given name of the employee. The character limit of this field is 25.

- Last Name: The Last Name field should indicate the legal surname of the employee. The character limit of this field is 25.

- Email: The Email field should indicate the best (i.e., most often used for business purposes) e-mail address for the employee. The character limit of this field is 25.

- Phone Number: The Phone Number field should indicate the best (i.e., most often used for business purposes) telephone number (land line or cellular) for the employee. The character limit of this field is 13.

- Company: The Company field should indicate the name of the company for which the employee works. The character limit of this field is 75.

- Tap Save in the top right corner of the screen to add the outside employee to the Safety Inspection.

|

|

|

|

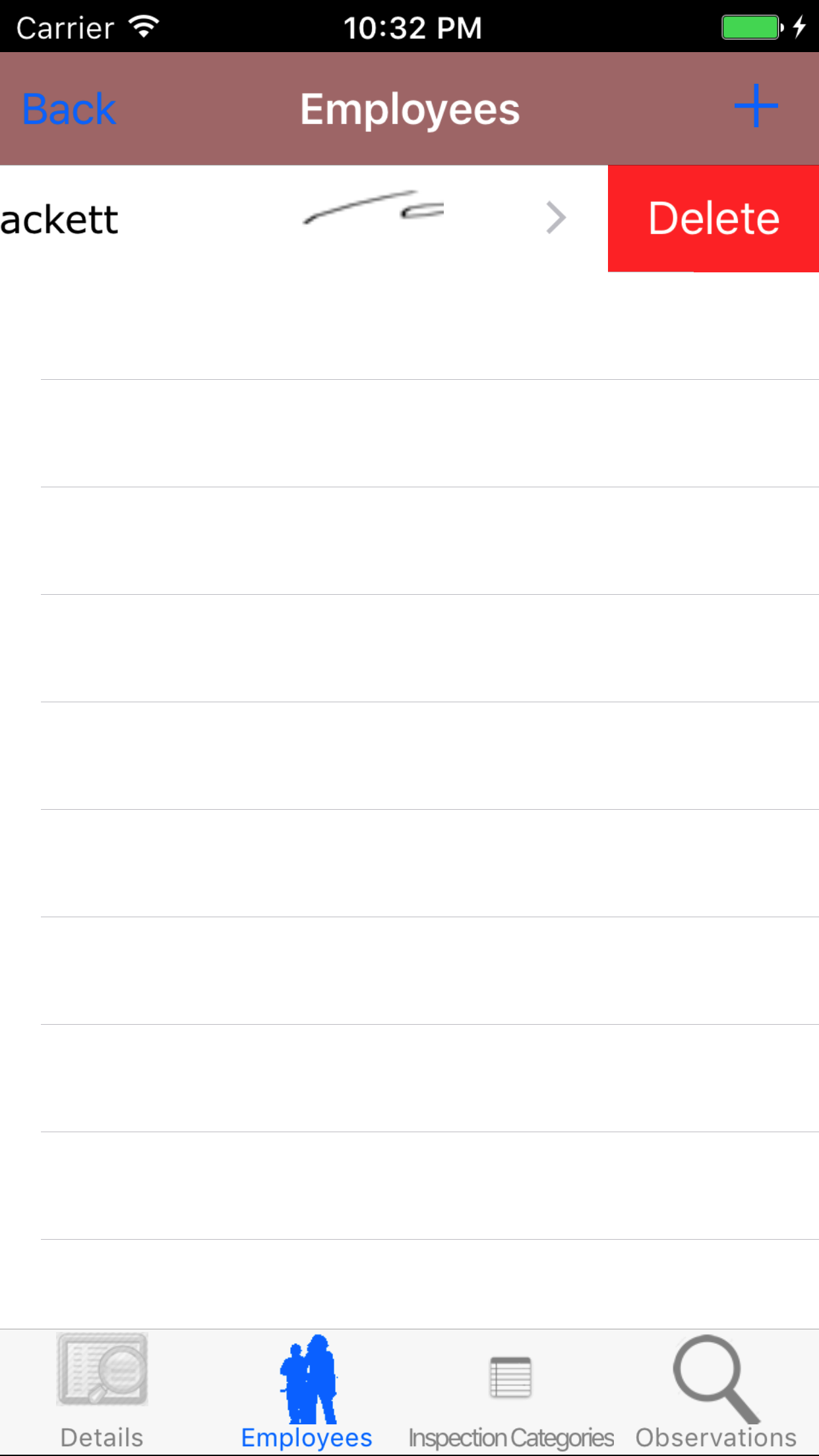

5.Delete Employee from Safety Inspection |

|

Once on the Safety Inspection you would like to Edit

Steps

- Tap the Employees icon at the bottom of the screen to open the Employees screen.

- Scroll the list of employees until the desired employee is displayed on the screen.

- Swipe from the right edge to the left to bring up the delete button for the employee.

- Tap the Delete button. The employee will be deleted.

|

|

| Steps 1-2 |

|

|

| Steps 3-4 |

|

|

|

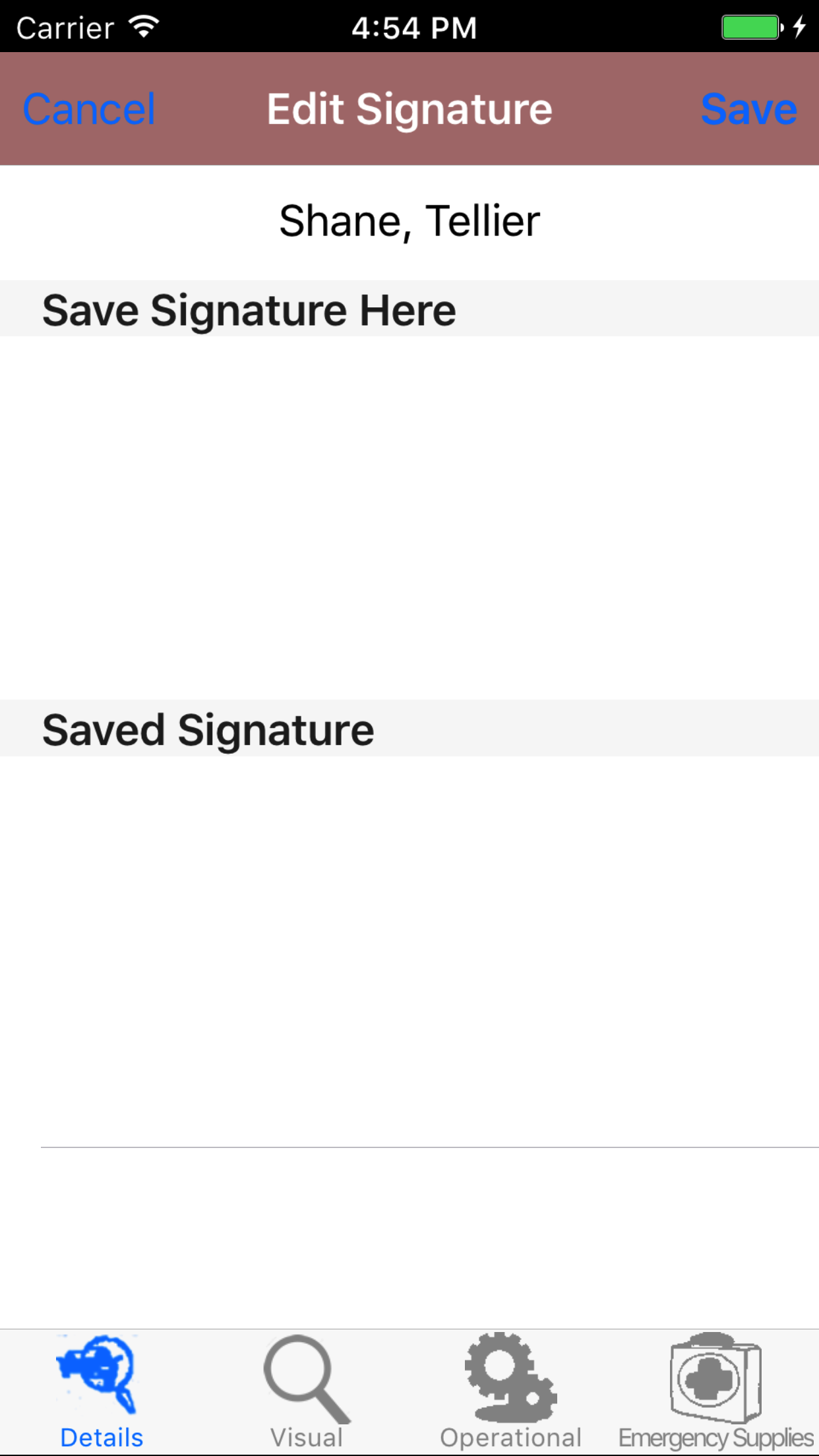

6.Add Employee Signature |

|

Each employee added to the Safety Inspection must provide an electronic signature to indicate that they have been made aware of all tasks and hazards and will comply with all safe work procedures and plans for elimination.

Once on the Safety Inspection you would like to Edit

Steps

- Tap the Employees icon at the bottom of the screen to open the Employees screen.

- Scroll the list of employees until the desired employee is displayed on the screen.

- Tap the desired employee to select them and open the Edit Employee screen

- Have the selected employee sign in the white space beneath the Save New Signature Here label.

- Tap Save in the top right corner of the screen to update the Saved Signature field.

The saved signature will appear below the signature entry screen.

|

|

| Steps 1-2 |

|

|

| Steps 3-4 |

|

|

|

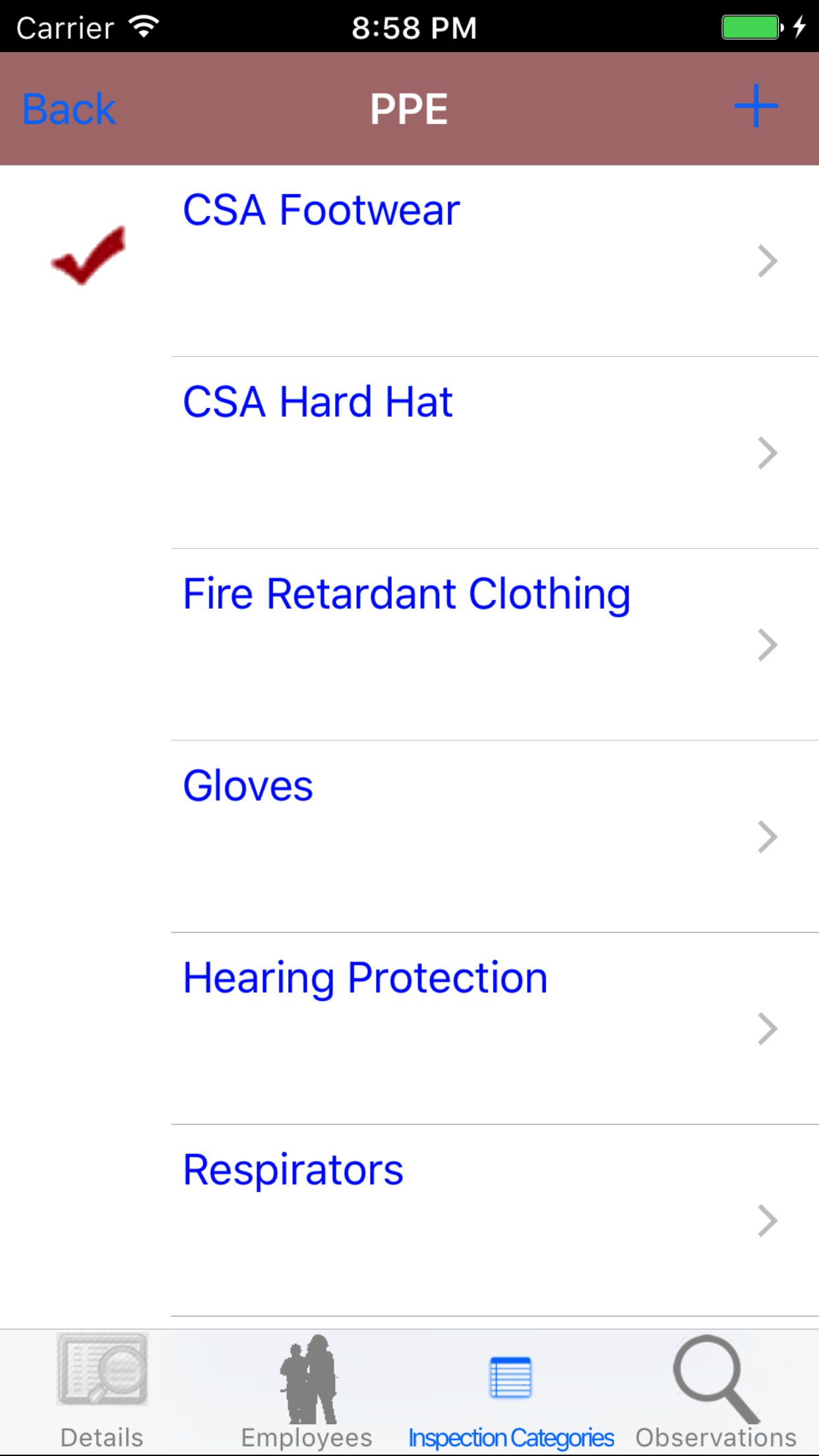

7.Edit Personal Protective Equipment Inspection Checklist |

|

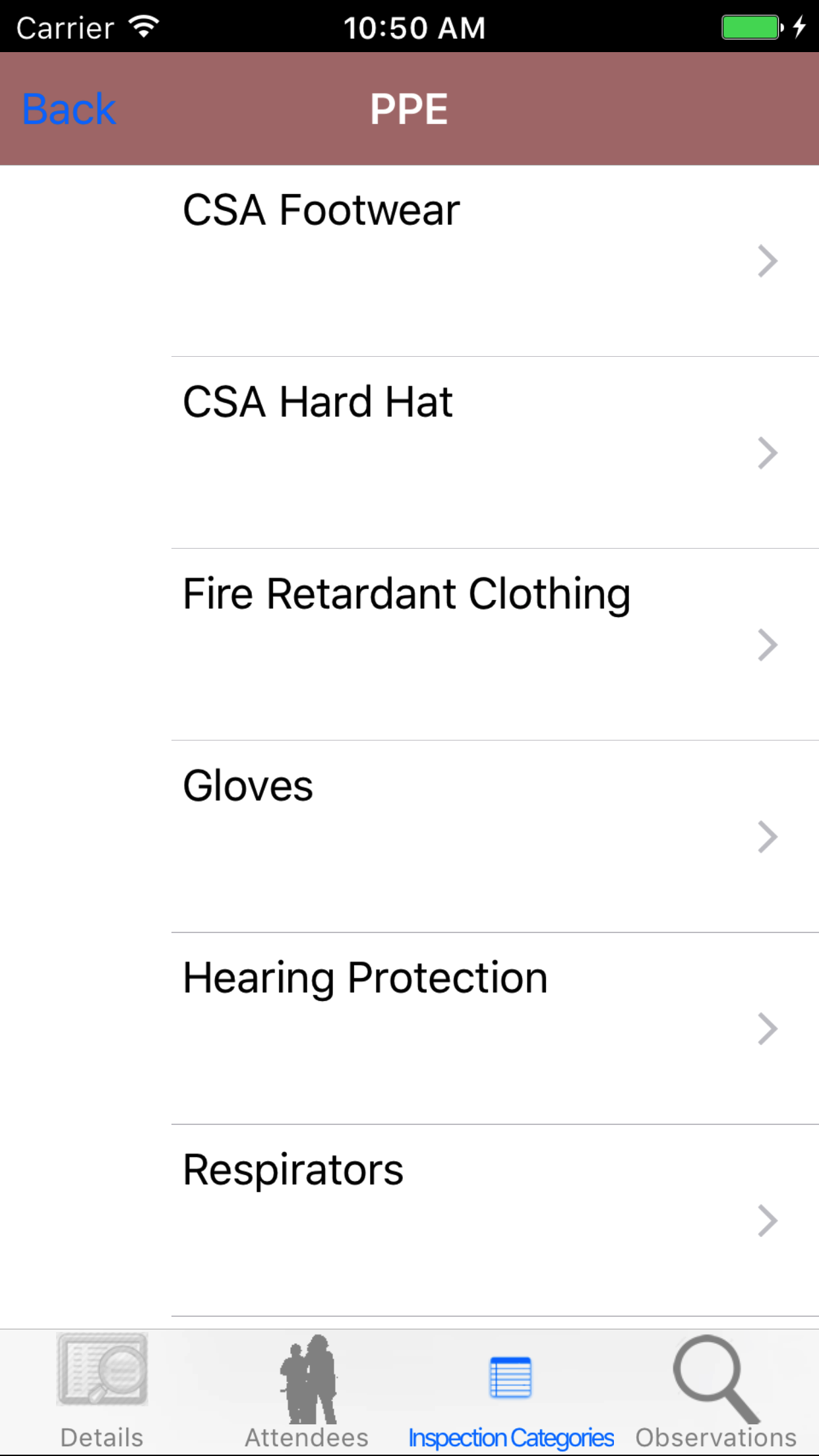

Personal Protective Equipment Inspection Tasks are safety inspection personal protective equipment inspection tasks that a company has set up for their field staff to complete

as part of their safety inspection. To ensure field staff have the most up to date copy of the inspection tasks a company is

using make sure to update your phone on a regular basis. For more information about updating your phone click here.

Once on the Safety Inspection you would like to Edit

Steps

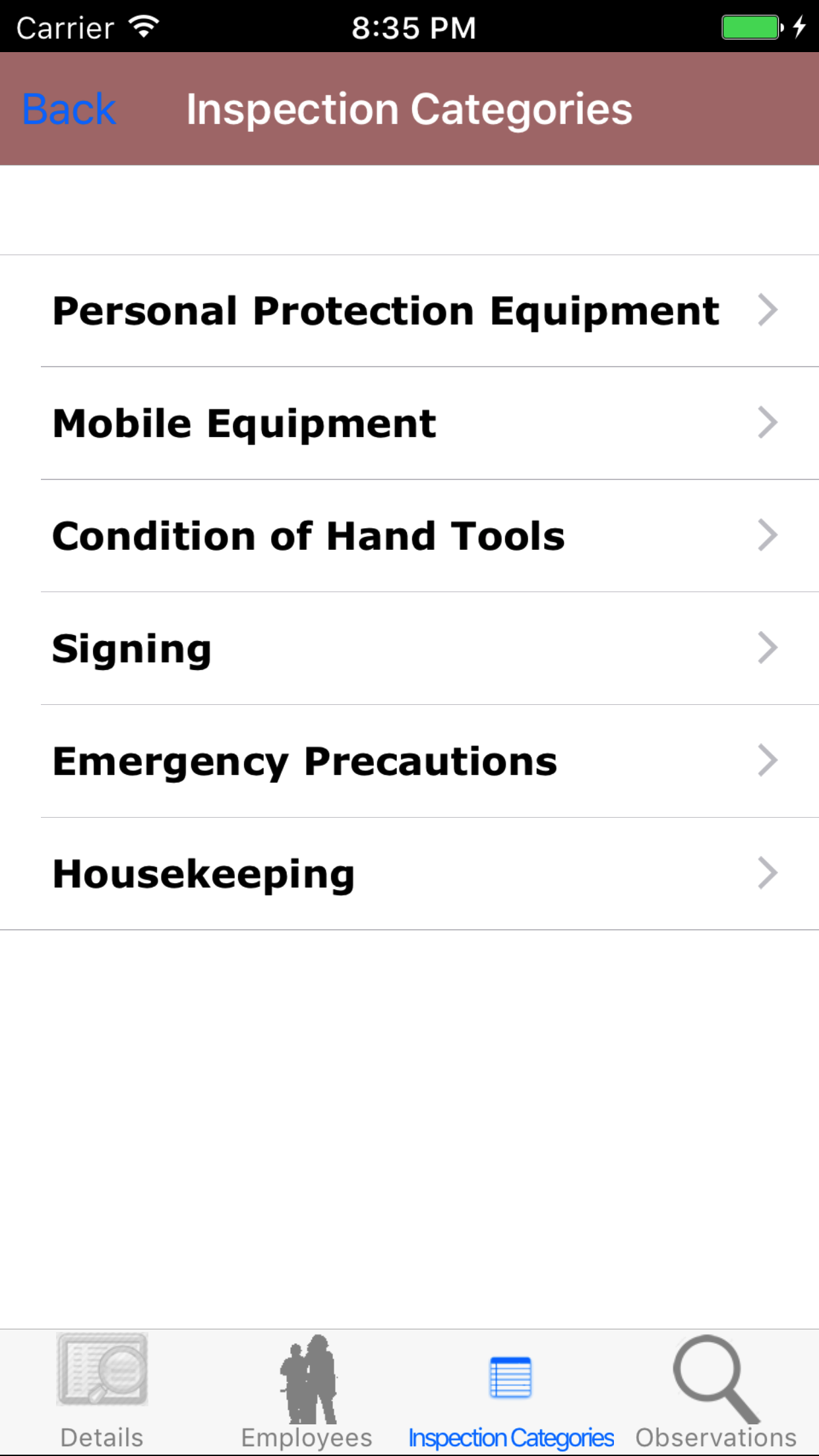

- Tap the Inspection Categories icon at the bottom of the screen to open the Inspection Categories Checklist screen. The screen loads

with the list of the 6 checklist categories of the safety inspection.

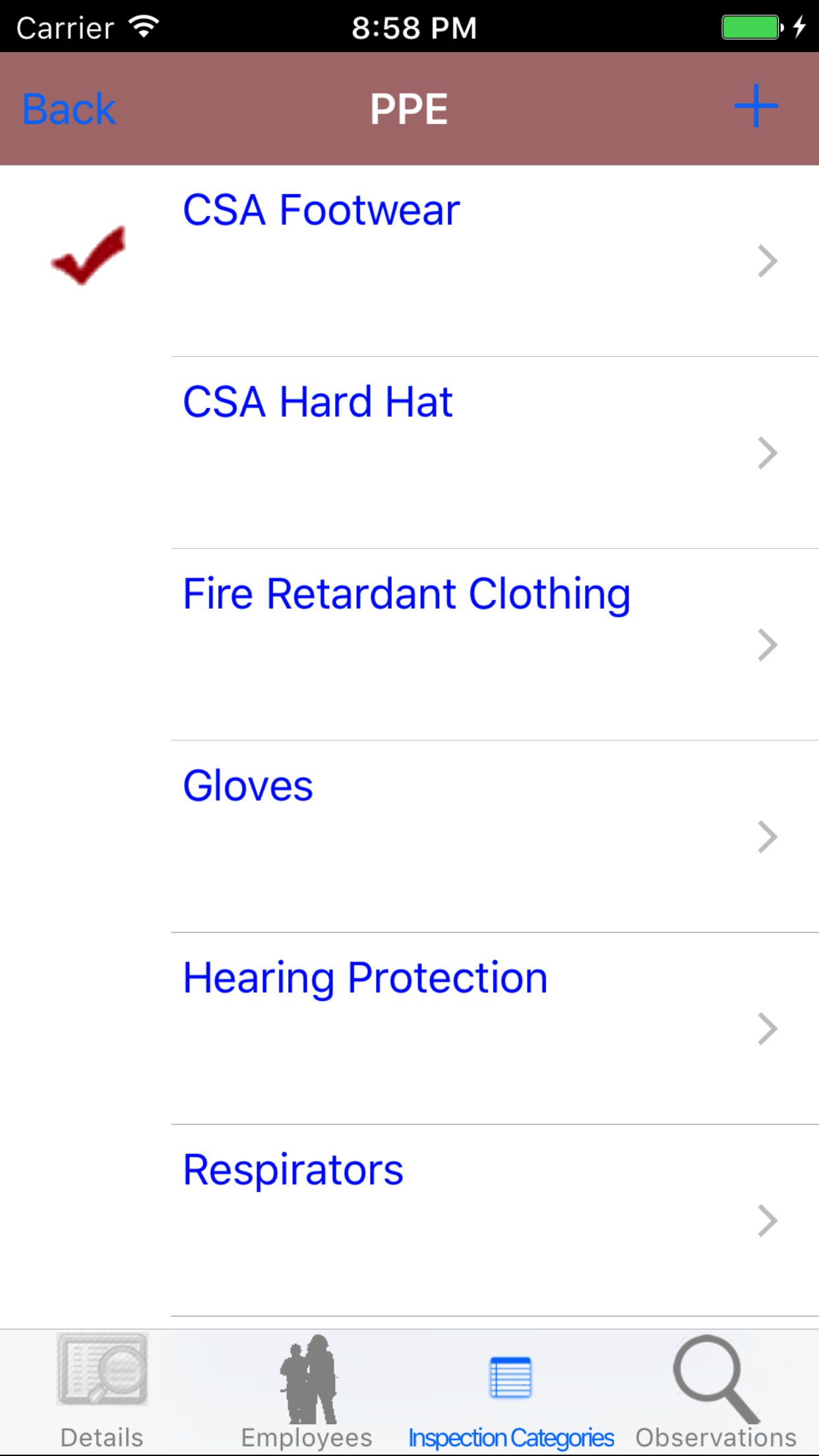

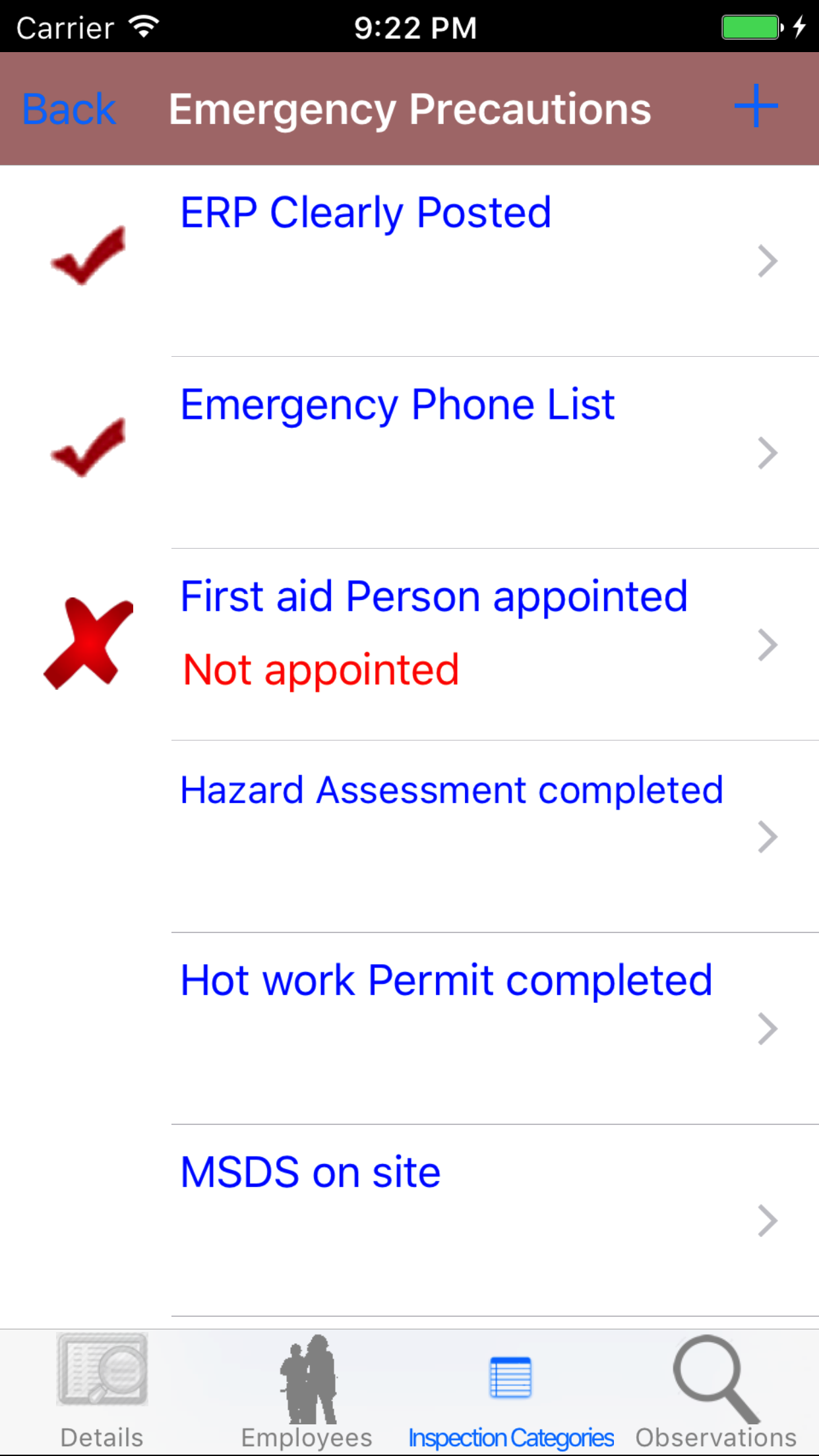

- Tap the Personal Protective Equipment button which loads with the personal protective equipment inspection tasks listed with Task Name

in blue, with the Deficiencies or Comments in red. A Checked icon will appear depending on the value of the checked flag for each inspection task

if the checked value is set to Yes, a Checkmark will appear, if the checked value is set to No, a X will appear and if the checked value is set to N/A a N/A will appear.

- Scroll the list of tasks until the desired task is displayed on the screen.

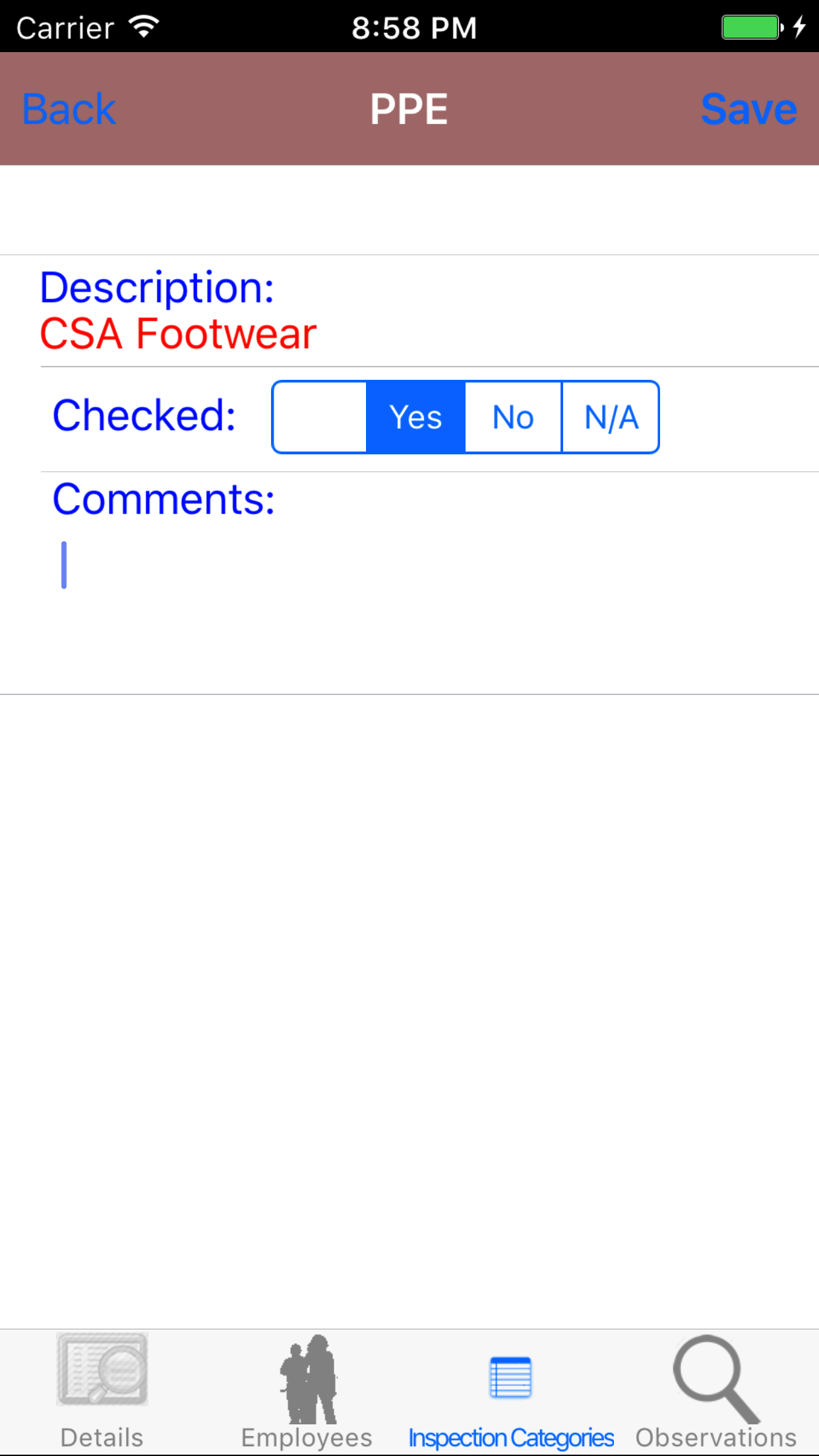

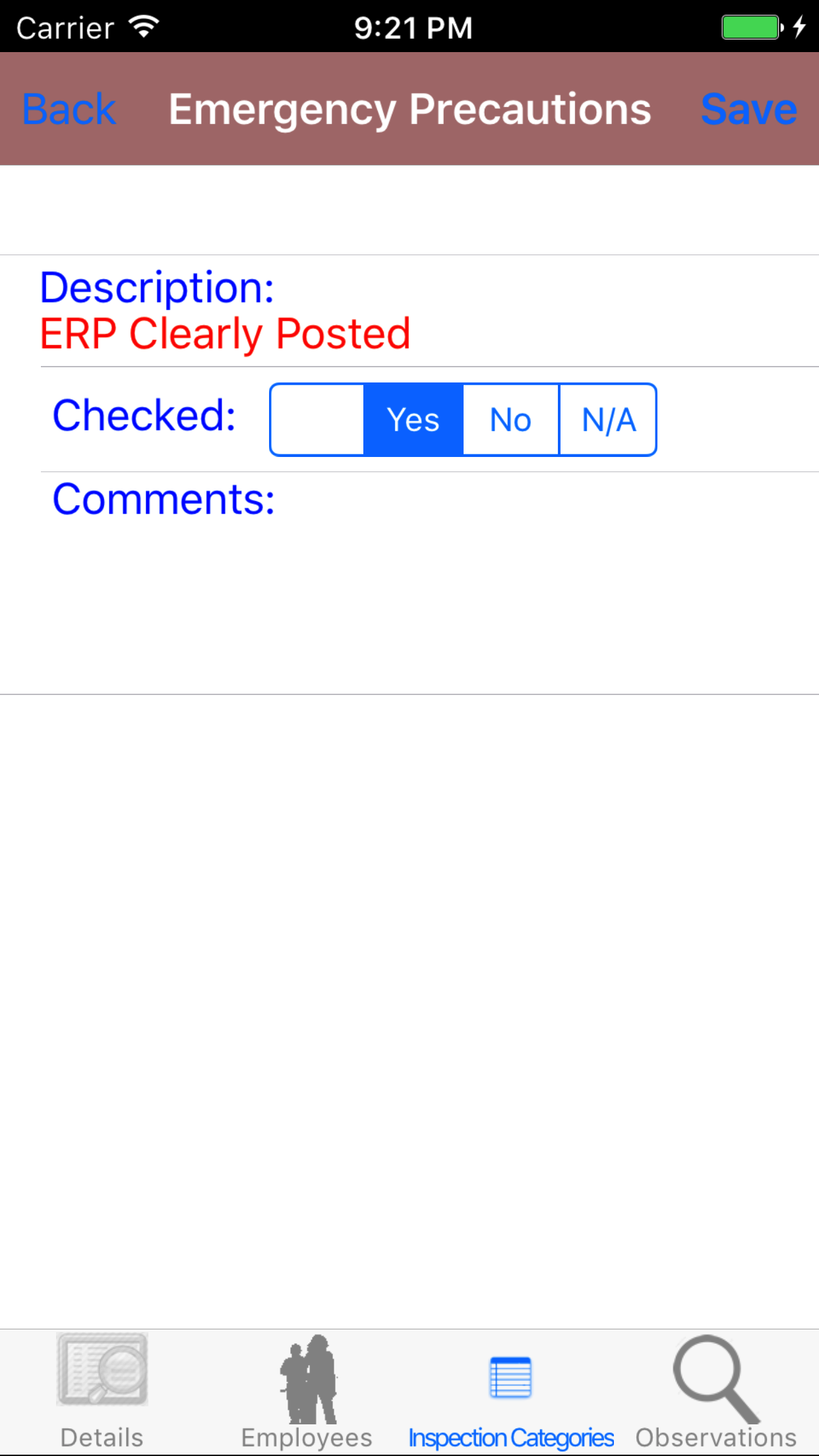

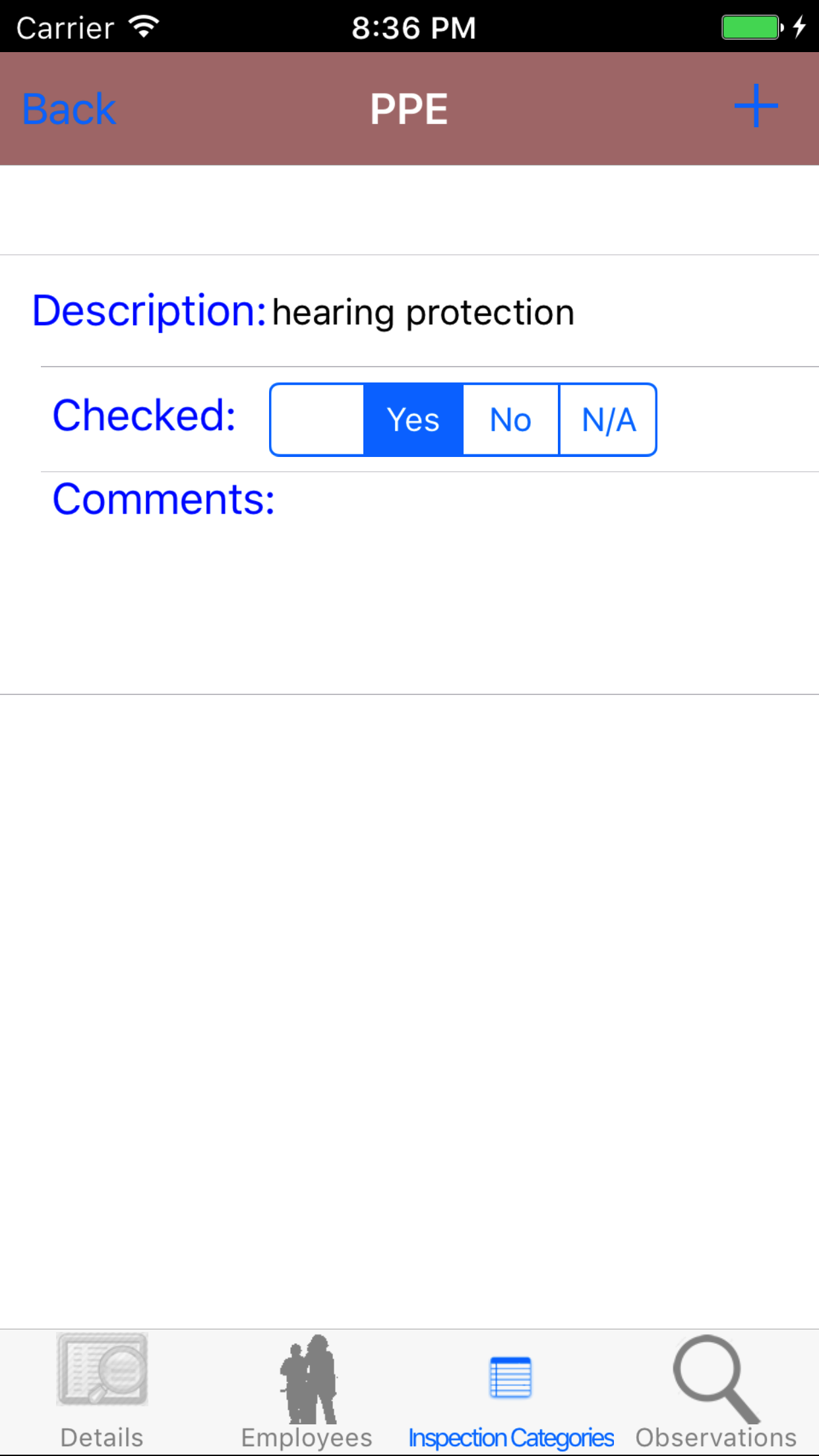

- Tap on the Task, which will load the Edit Inspection Task screen.

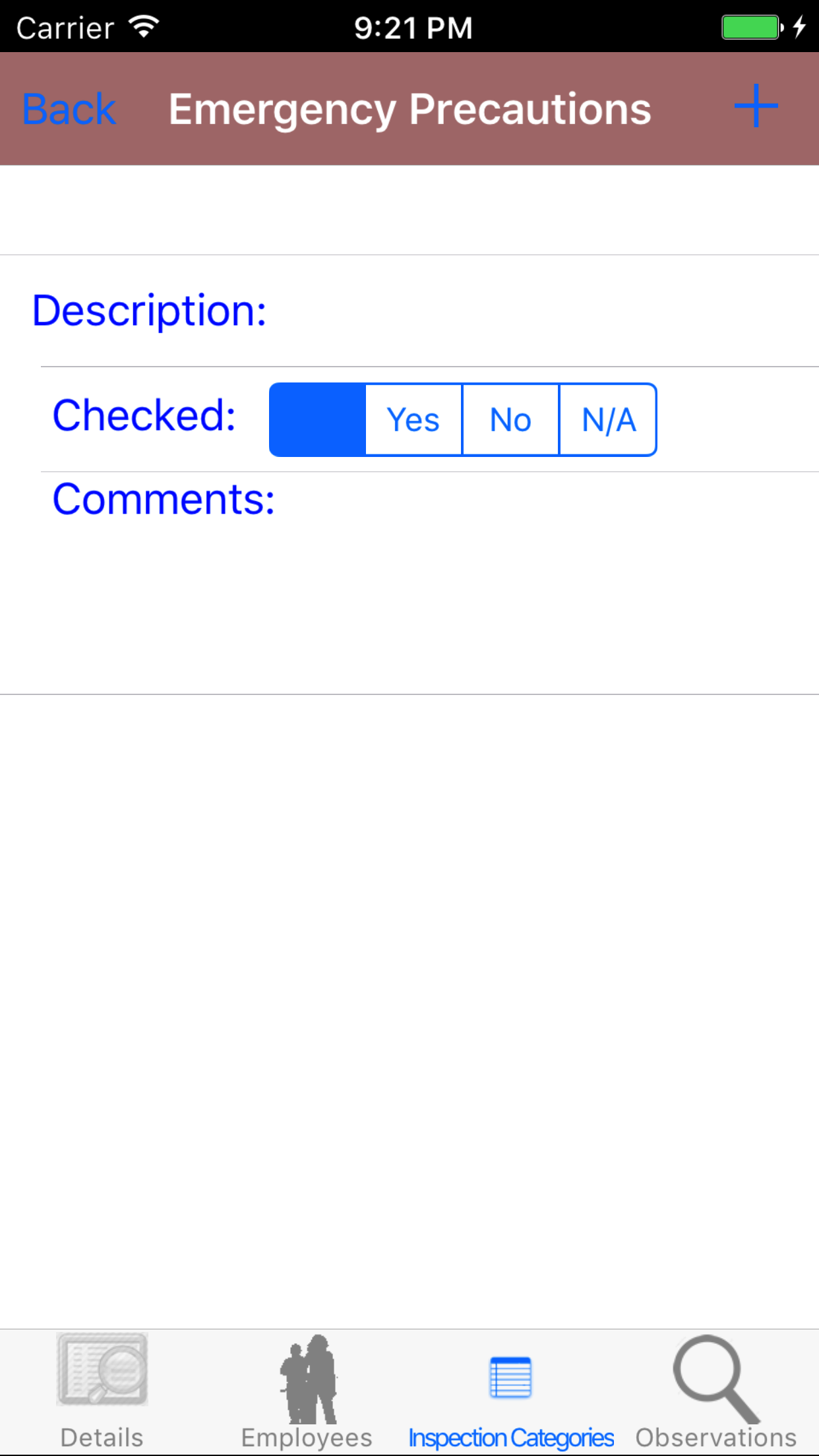

The next screen loads with the Description of the task at the top of the screen and the ability to change the checked

status and deficiency or comment field.

Fields

- Checked: Tap __|Sat.|Req.|N/A to change the status of the inspection task.

- __: means task has not been checked.

- Sat.: means inspection tasks has been found to be satisfactory.

- Req.: means inspection tasks has been found to be requires attention. Any task marked as Req. requires a description

of the issue to be written in the deficiency or comments field.

- N/A: means inspection tasks is not applicable to the safety inspection.

- Deficiency or Comments: The Deficiency or Comments field gives the user the ability to describe the issues found with the

subject of the the inspection task. The user should enter a description or a comment about the problem found. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the personal protective equipment inspection task details

|

|

| Step 1 |

|

|

| Steps 2-3 |

|

|

| Steps 4-6 |

|

|

|

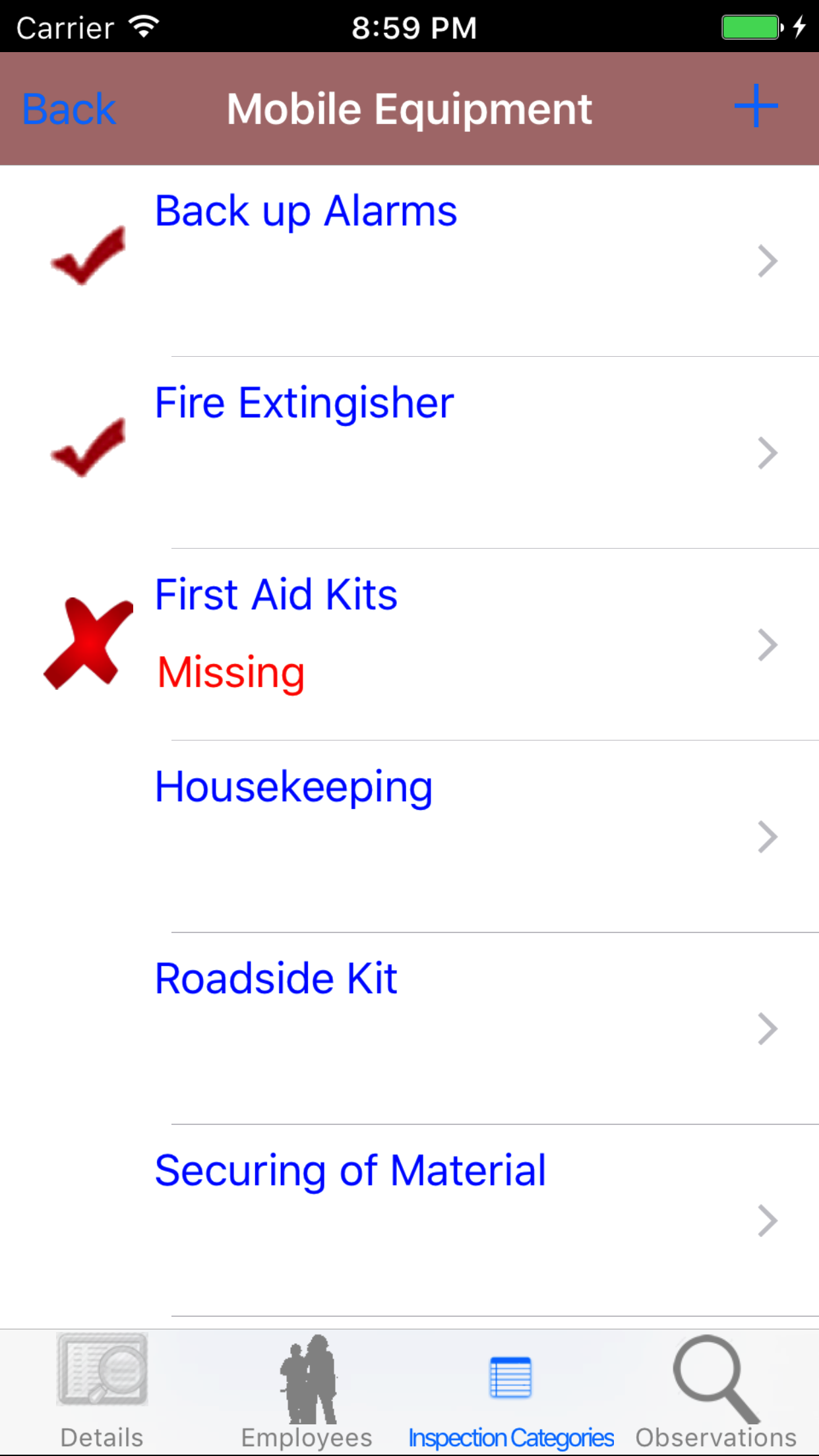

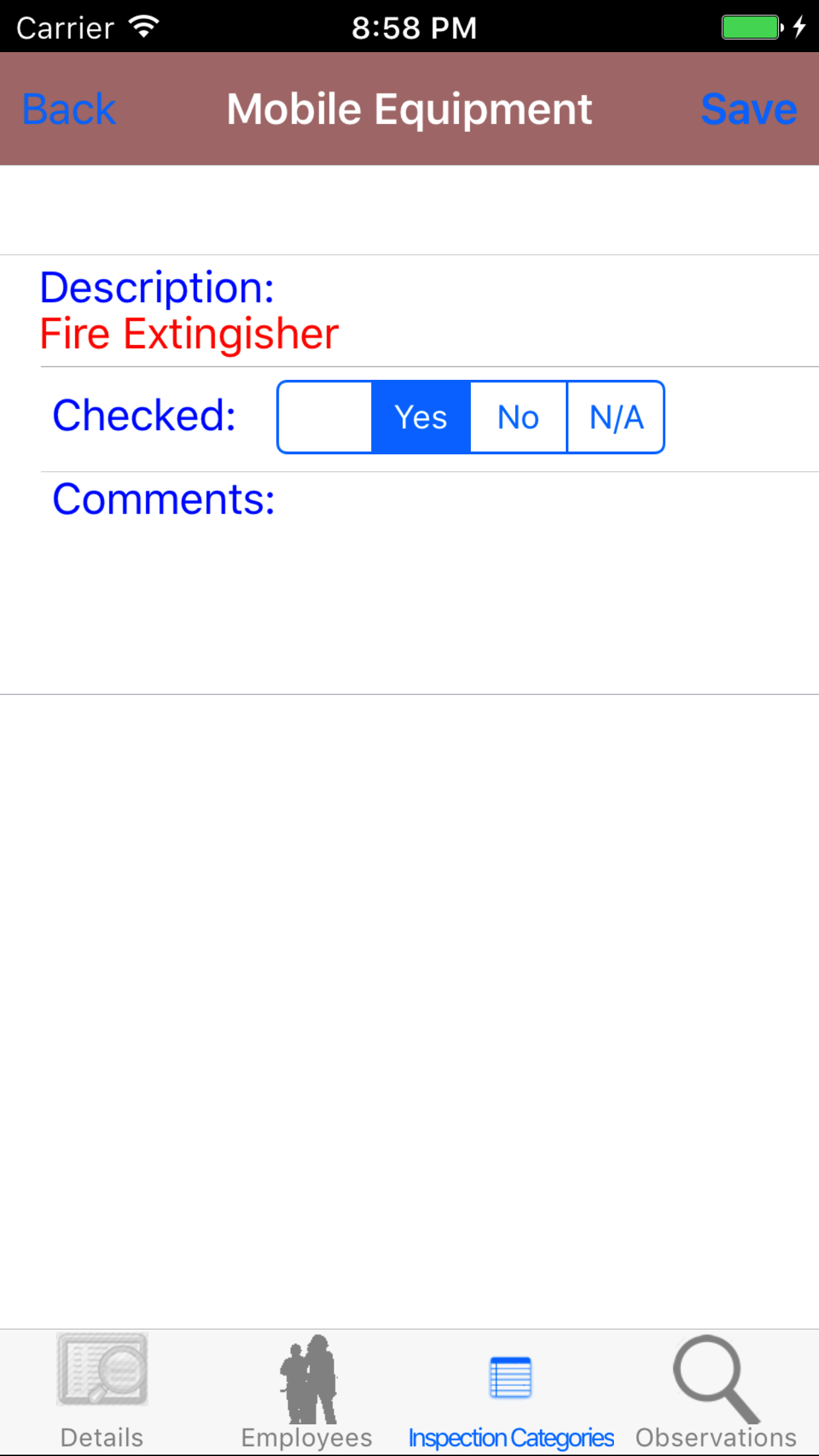

8.Edit Mobile Equipment Inspection Checklist |

|

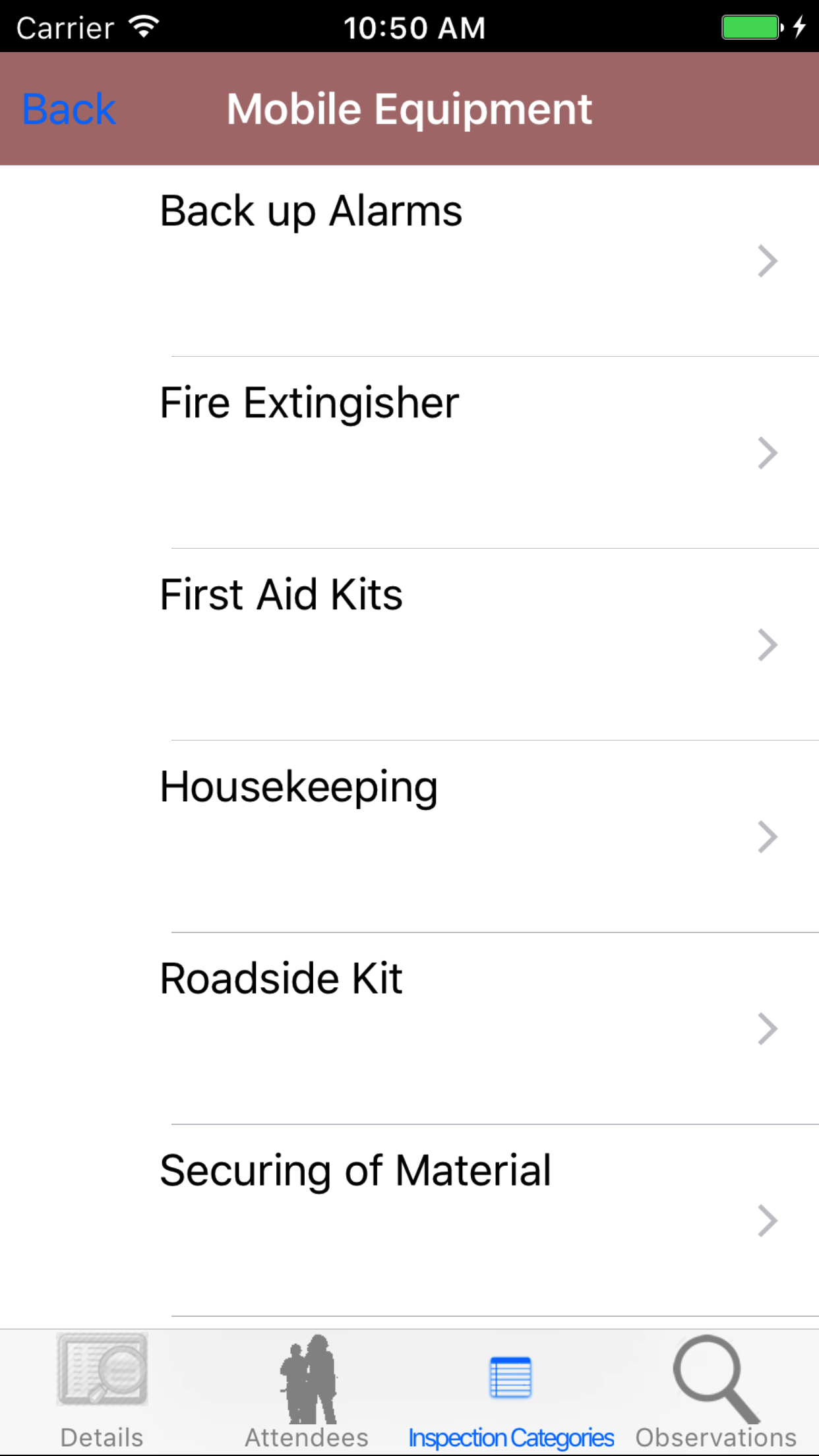

Mobile Equipment Tasks are safety inspection mobile equipment inspection tasks that a company has set up for their field staff to complete

as part of their safety inspection. To ensure field staff have the most up to date copy of the inspection tasks a company is

using make sure to update your phone on a regular basis. For more information about updating your phone click here.

Once on the Vehicle Inspection you would like to Edit

Steps

- Tap the Inspection Categories icon at the bottom of the screen to open the Inspection Categories Checklist screen. The screen loads

with the list of the 6 checklist categories of the safety inspection.

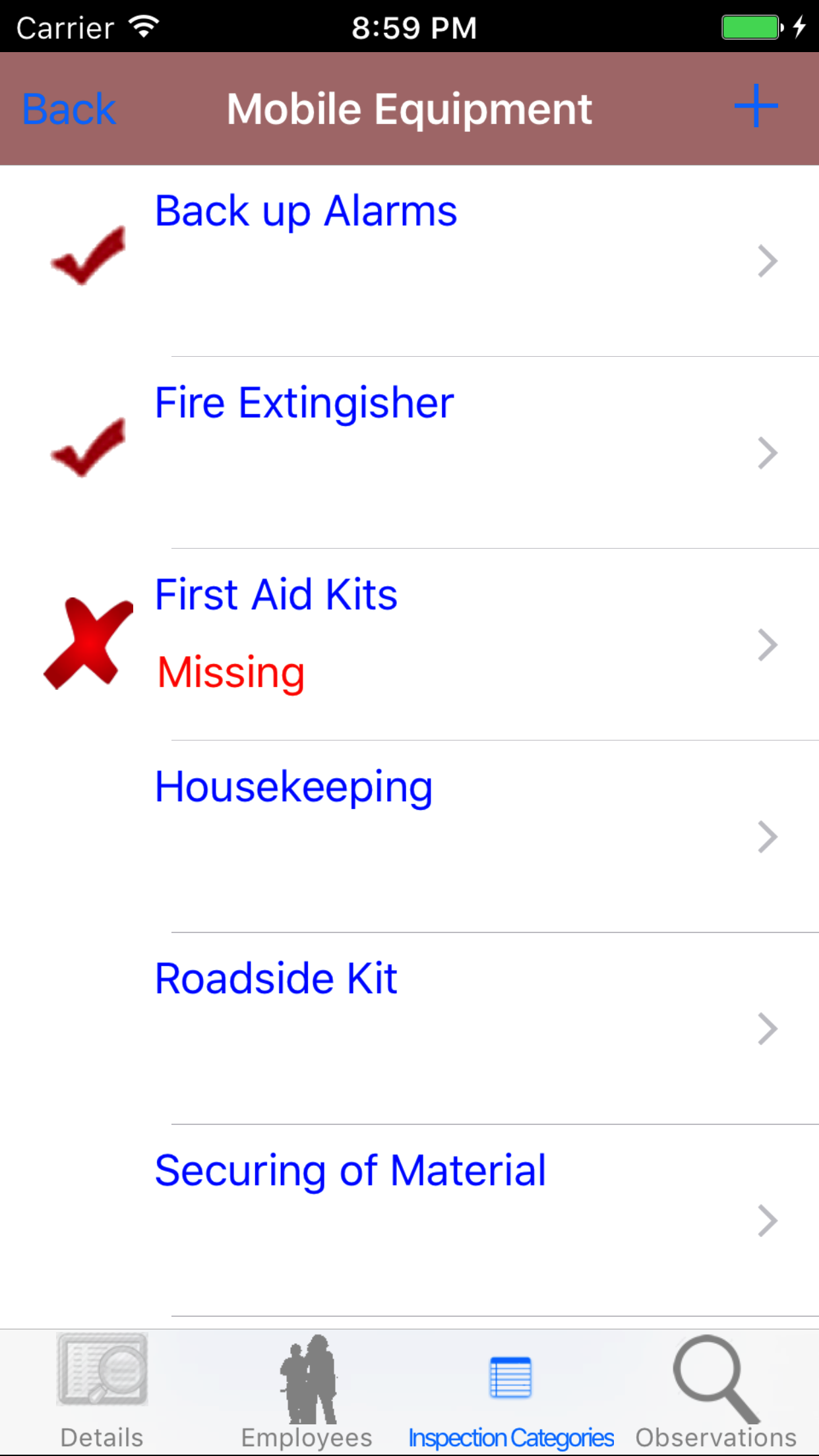

- Tap the Mobile Equipment button which loads with the mobile equipment inspection tasks listed with Task Name

in blue, with the Deficiencies or Comments in red. A Checked icon will appear depending on the value of the checked flag for each inspection task

if the checked value is set to Yes, a Checkmark will appear, if the checked value is set to No, a X will appear and if the checked value is set to N/A a N/A will appear.

- Scroll the list of tasks until the desired task is displayed on the screen.

- Tap on the Task, which will load the Edit Inspection Task screen.

The next screen loads with the Description of the task at the top of the screen and the ability to change the checked

status and deficiency or comment field.

Fields

- Checked: Tap __|Sat.|Req.|N/A to change the status of the inspection task.

- __: means task has not been checked.

- Sat.: means inspection tasks has been found to be satisfactory.

- Req.: means inspection tasks has been found to be requires attention. Any task marked as Req. requires a description

of the issue to be written in the deficiency or comments field.

- N/A: means inspection tasks is not applicable to the safety inspection.

- Deficiency or Comments: The Deficiency or Comments field gives the user the ability to describe the issues found with the

subject of the the inspection task. The user should enter a description or a comment about the problem found. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the mobile equipment inspection task details

|

|

| Step 1 |

|

|

| Steps 2-3 |

|

|

| Steps 4-6 |

|

|

|

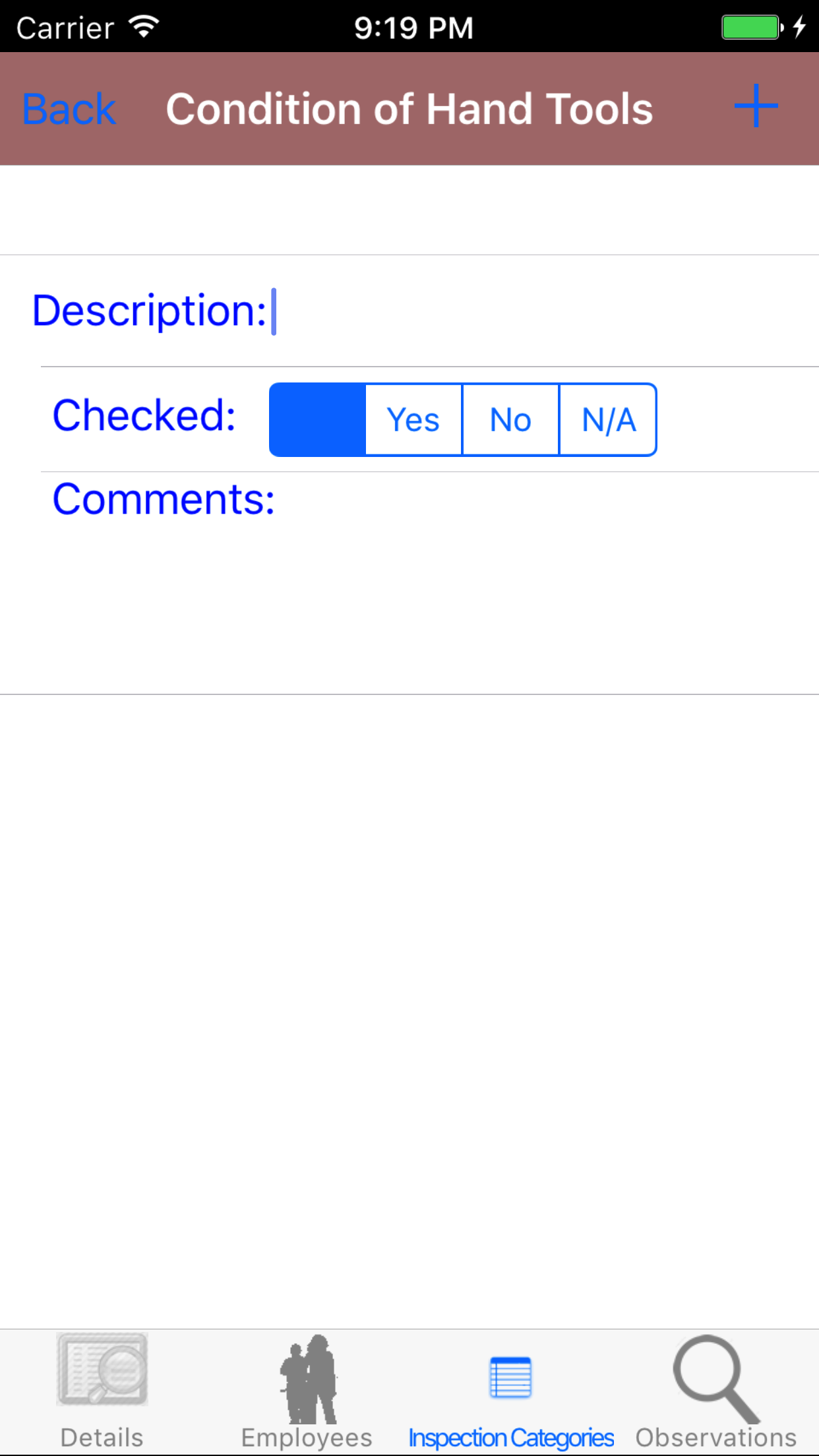

9.Edit Condition of Hand Tools Inspection Checklist |

|

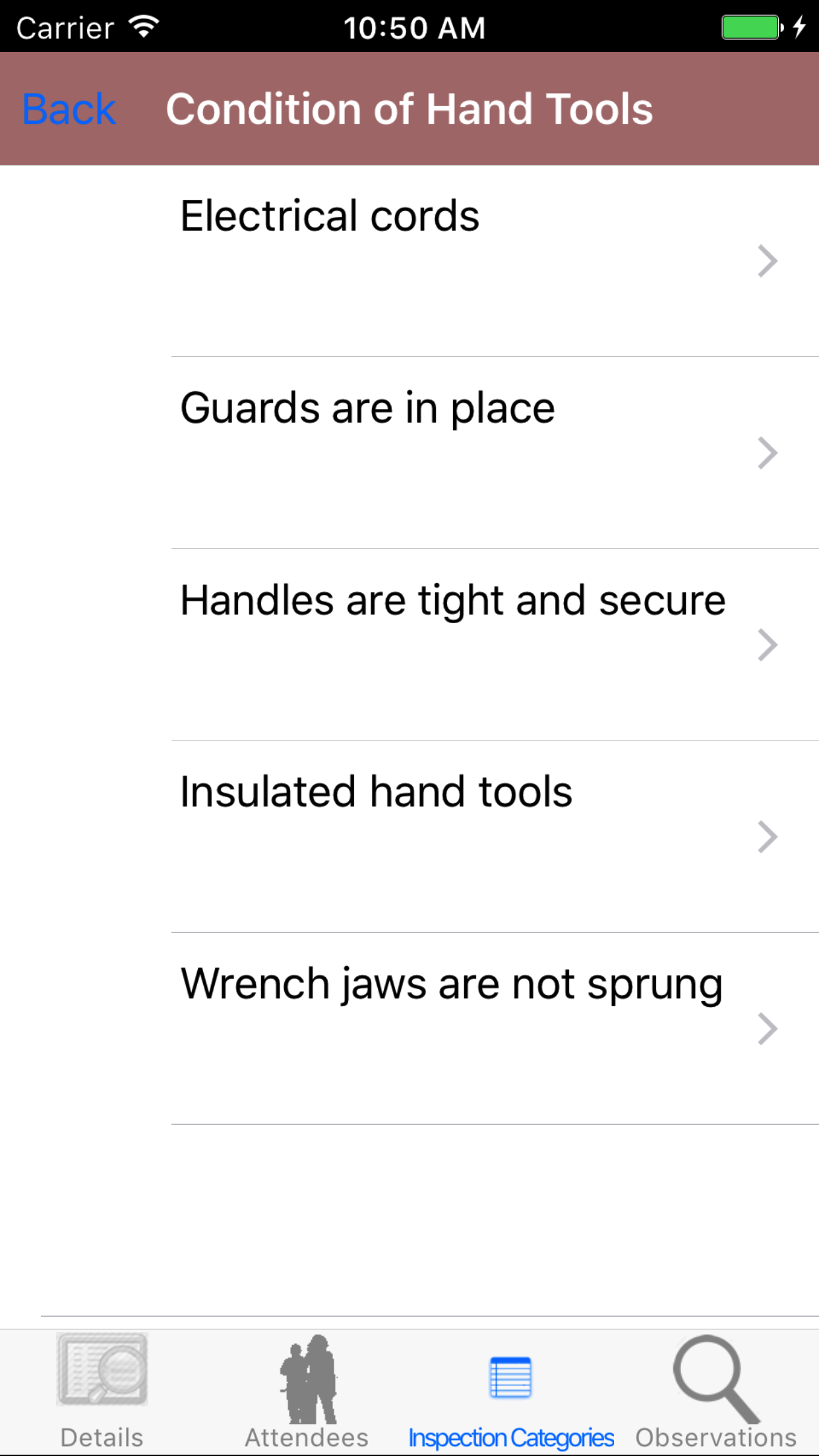

Condition of Hand Tools Inspection Tasks are vehicle inspection condition of hand tools inspection tasks that a company has set up for their field staff to complete

as part of their safety inspection. To ensure field staff have the most up to date copy of the inspection tasks a company is

using make sure to update your phone on a regular basis. For more information about updating your phone click here.

Once on the Safety Inspection you would like to Edit

Steps

- Tap the Inspection Categories icon at the bottom of the screen to open the Inspection Categories Checklist screen. The screen loads

with the list of the 6 checklist categories of the safety inspection.

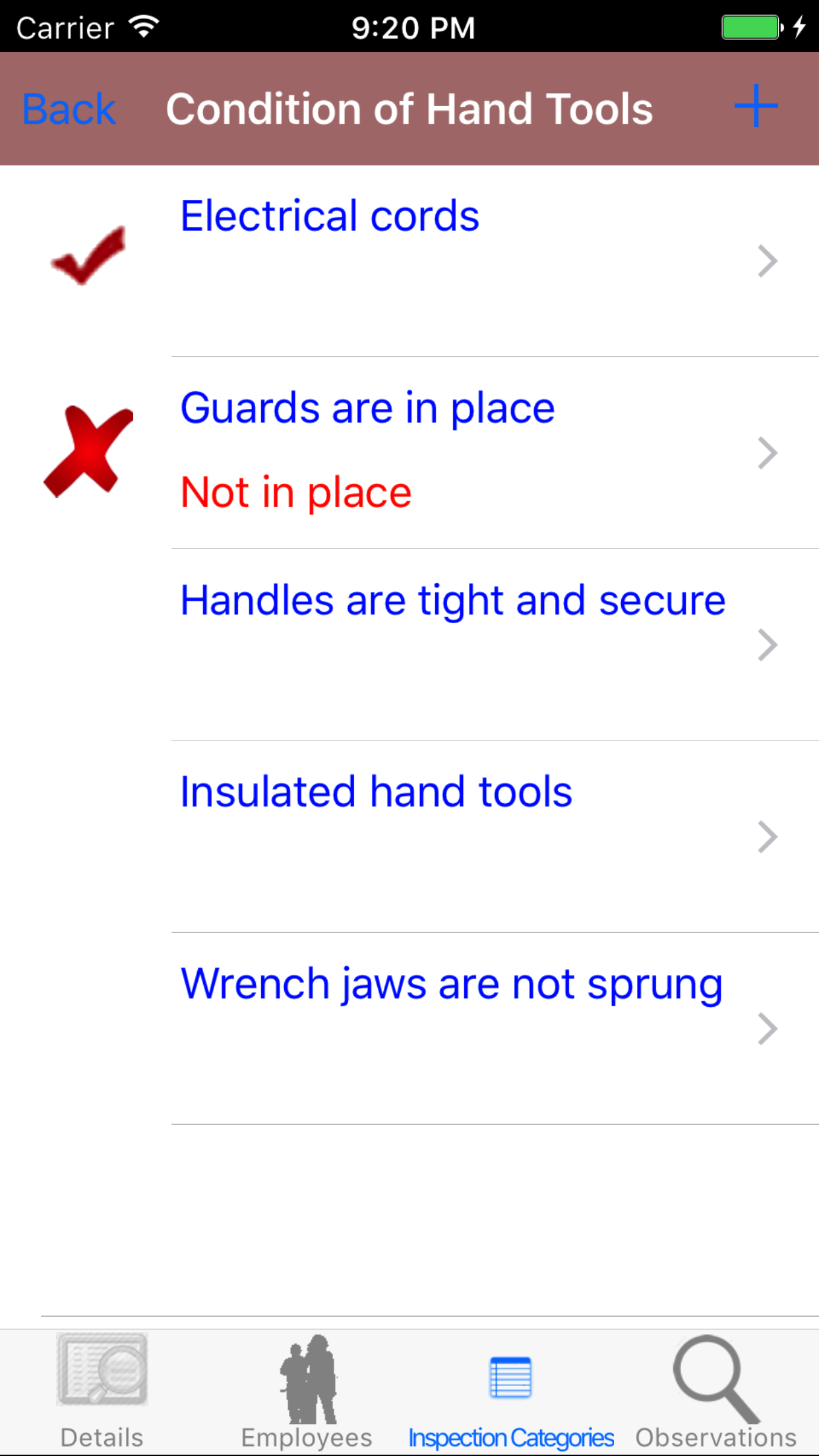

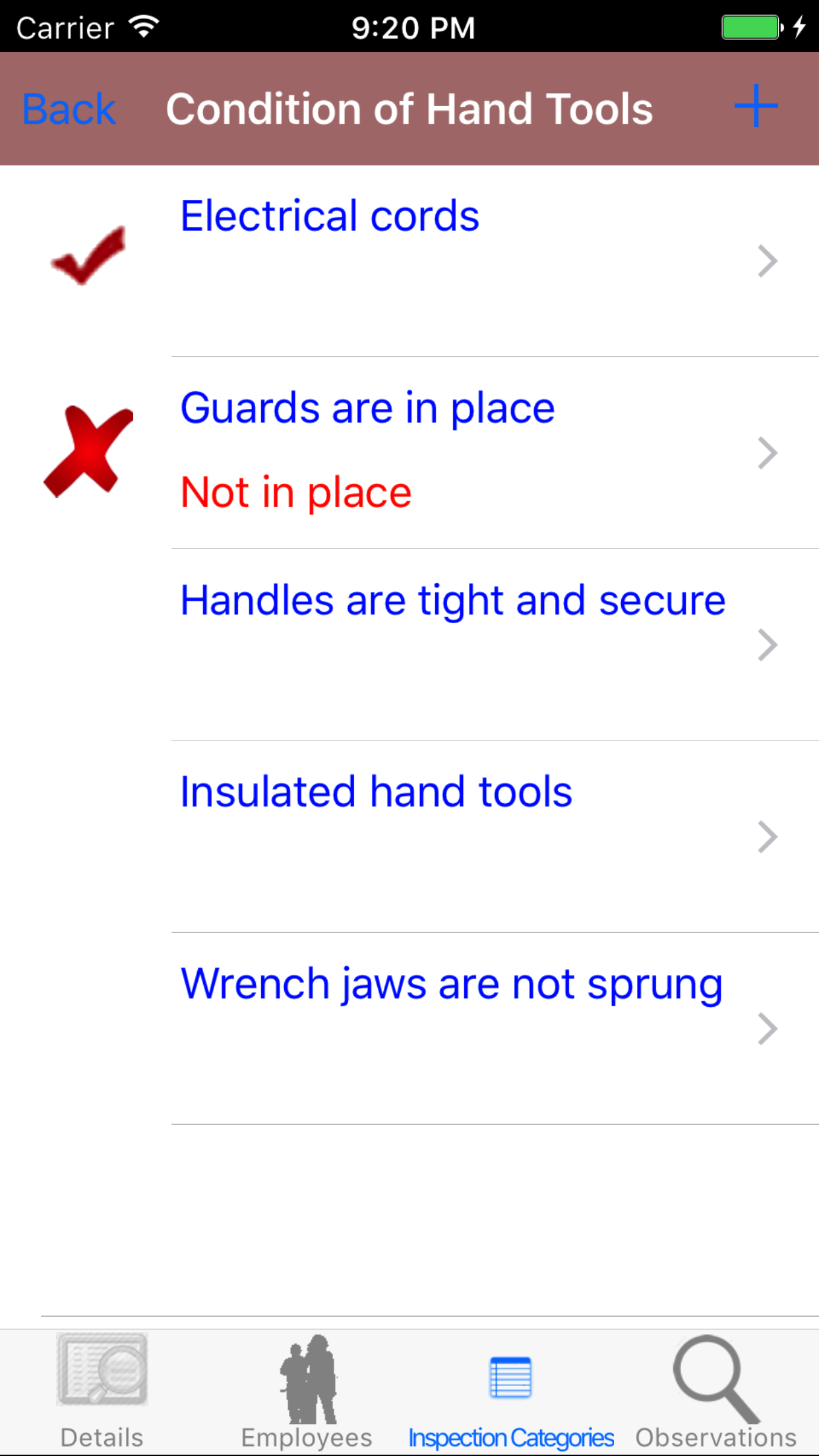

- Tap the Condition of Hand Tools button which loads with the condition of hand tools inspection tasks listed with Task Name

in blue, with the Deficiencies or Comments in red. A Checked icon will appear depending on the value of the checked flag for each inspection task

if the checked value is set to Yes, a Checkmark will appear, if the checked value is set to No, a X will appear and if the checked value is set to N/A a N/A will appear.

- Scroll the list of tasks until the desired task is displayed on the screen.

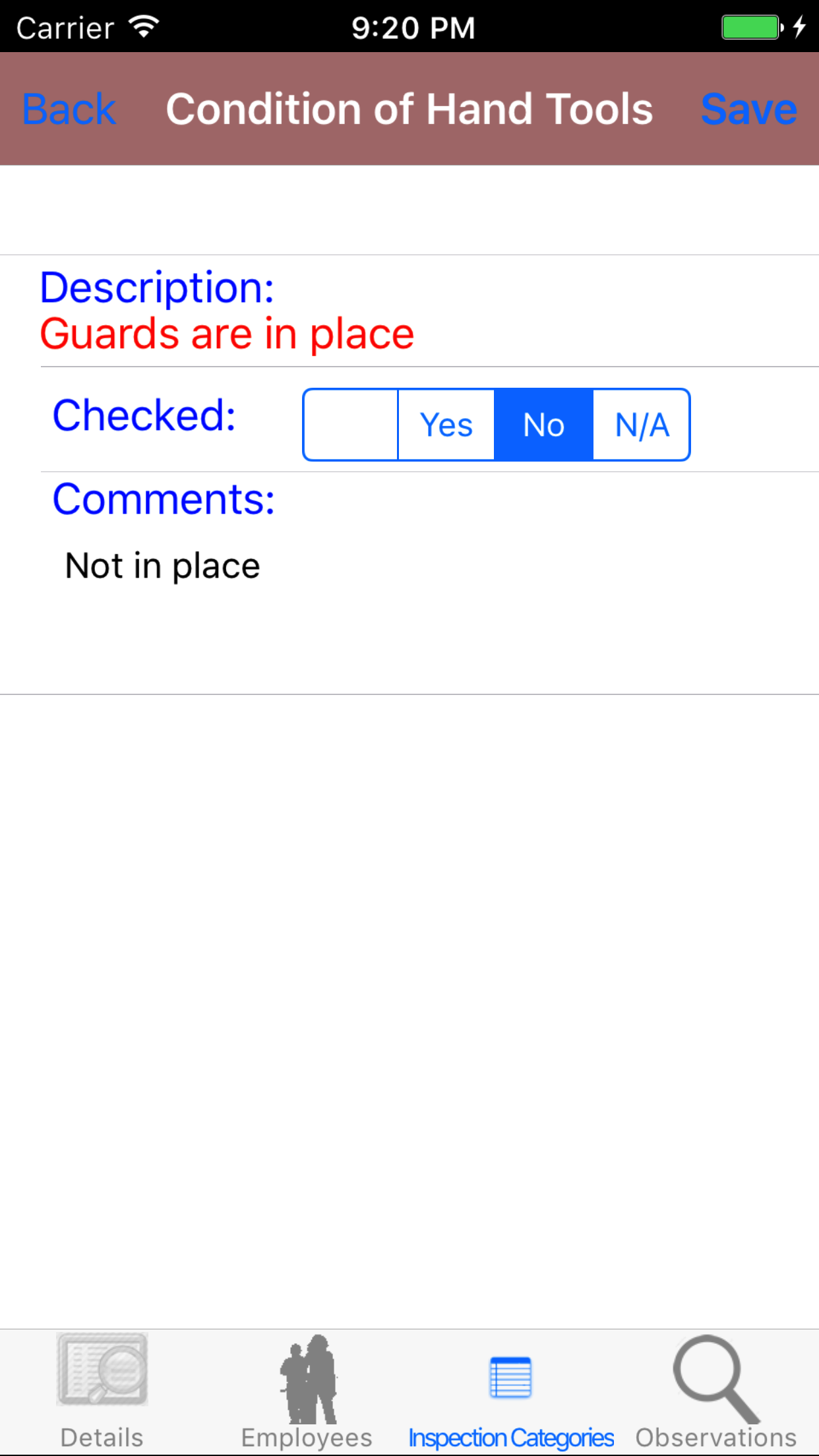

- Tap on the Task, which will load the Edit Inspection Task screen.

The next screen loads with the Description of the task at the top of the screen and the ability to change the checked

status and deficiency or comment field.

Fields

- Checked: Tap __|Sat.|Req.|N/A to change the status of the inspection task.

- __: means task has not been checked.

- Sat.: means inspection tasks has been found to be satisfactory.

- Req.: means inspection tasks has been found to be requires attention. Any task marked as Req. requires a description

of the issue to be written in the deficiency or comments field.

- N/A: means inspection tasks is not applicable to the safety inspection.

- Deficiency or Comments: The Deficiency or Comments field gives the user the ability to describe the issues found with the

subject of the the inspection task. The user should enter a description or a comment about the problem found. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the condition of hand tools inspection task details

|

|

| Step 1 |

|

|

| Steps 2-3 |

|

|

| Steps 4-6 |

|

|

|

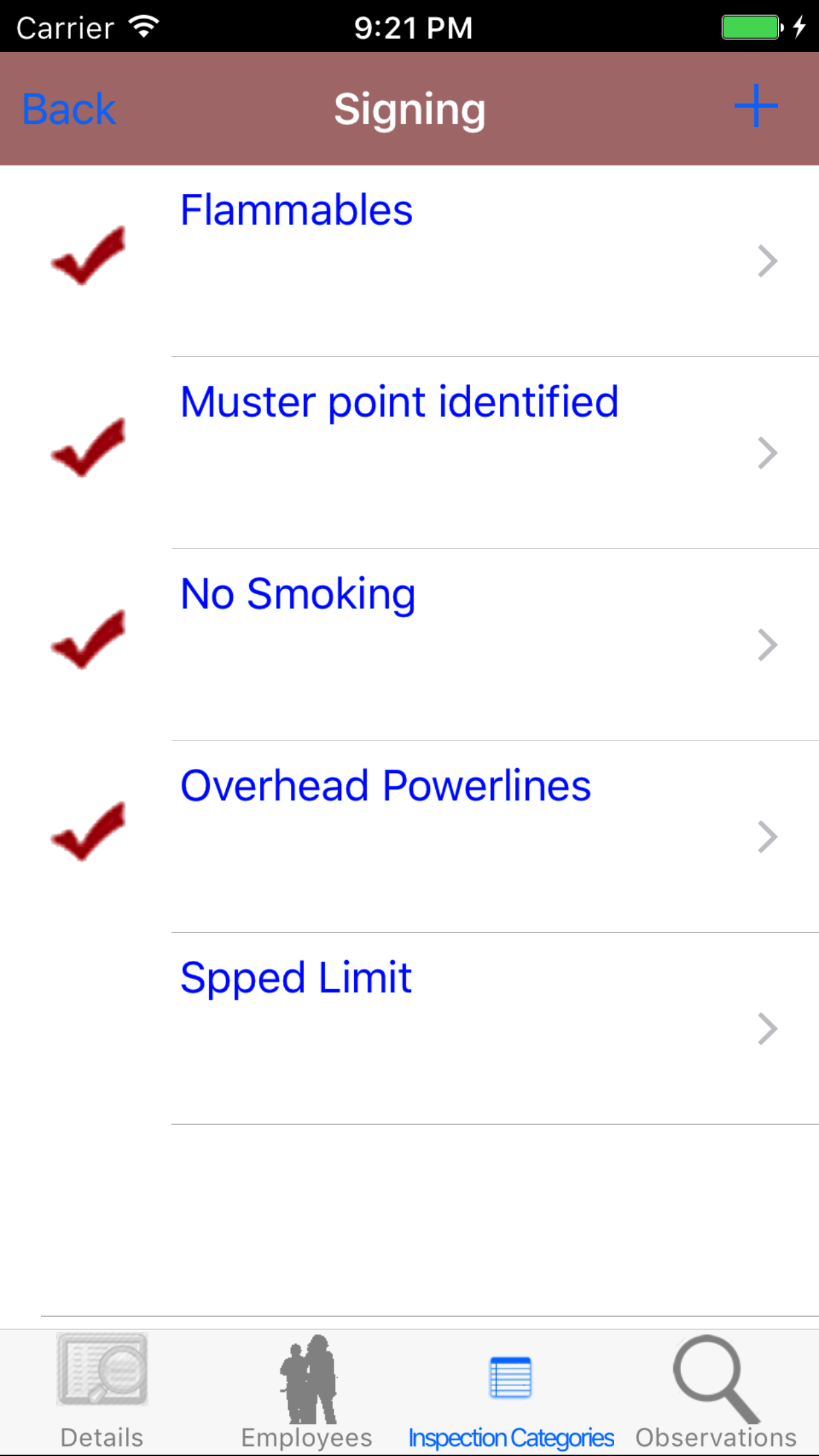

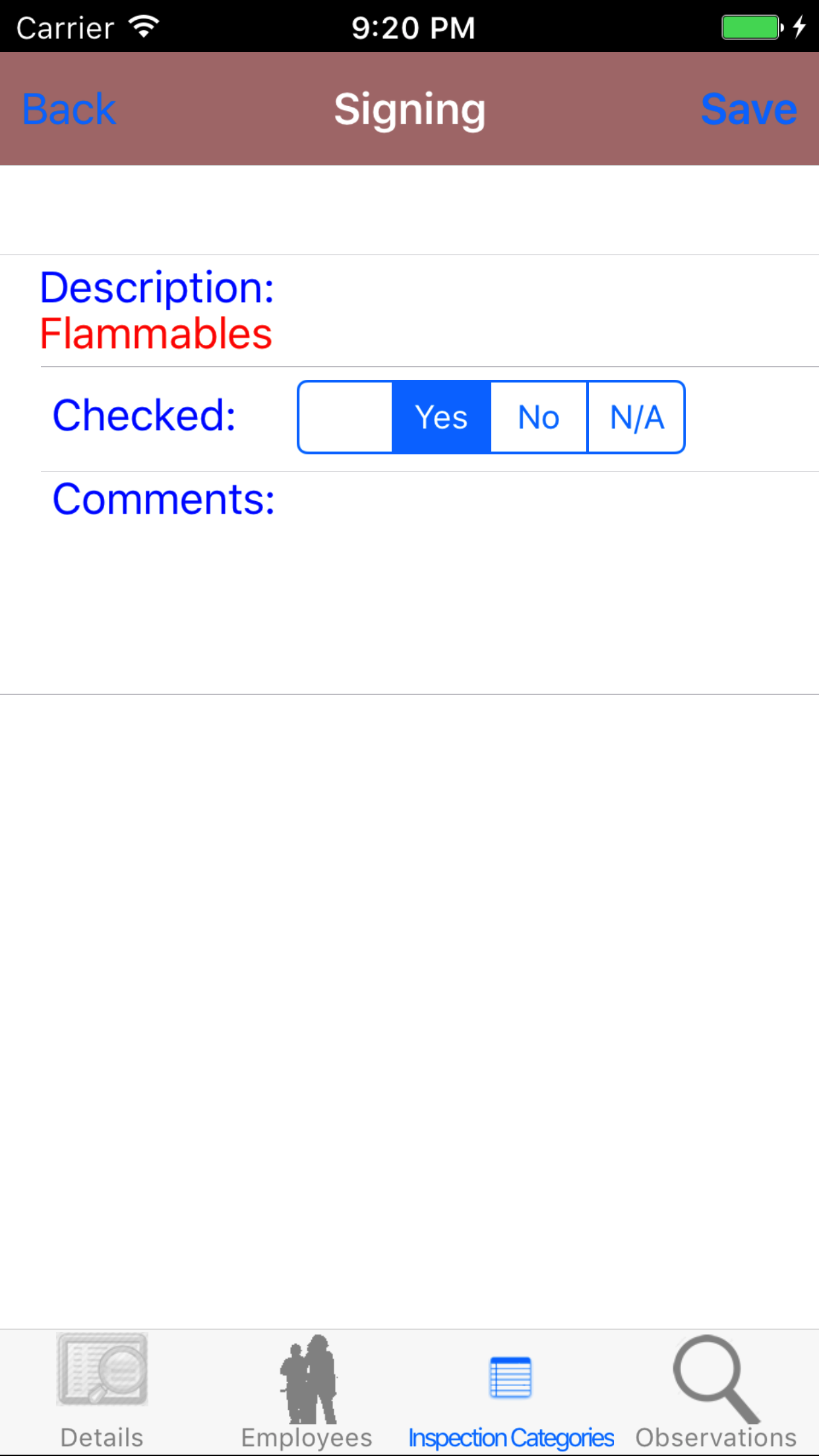

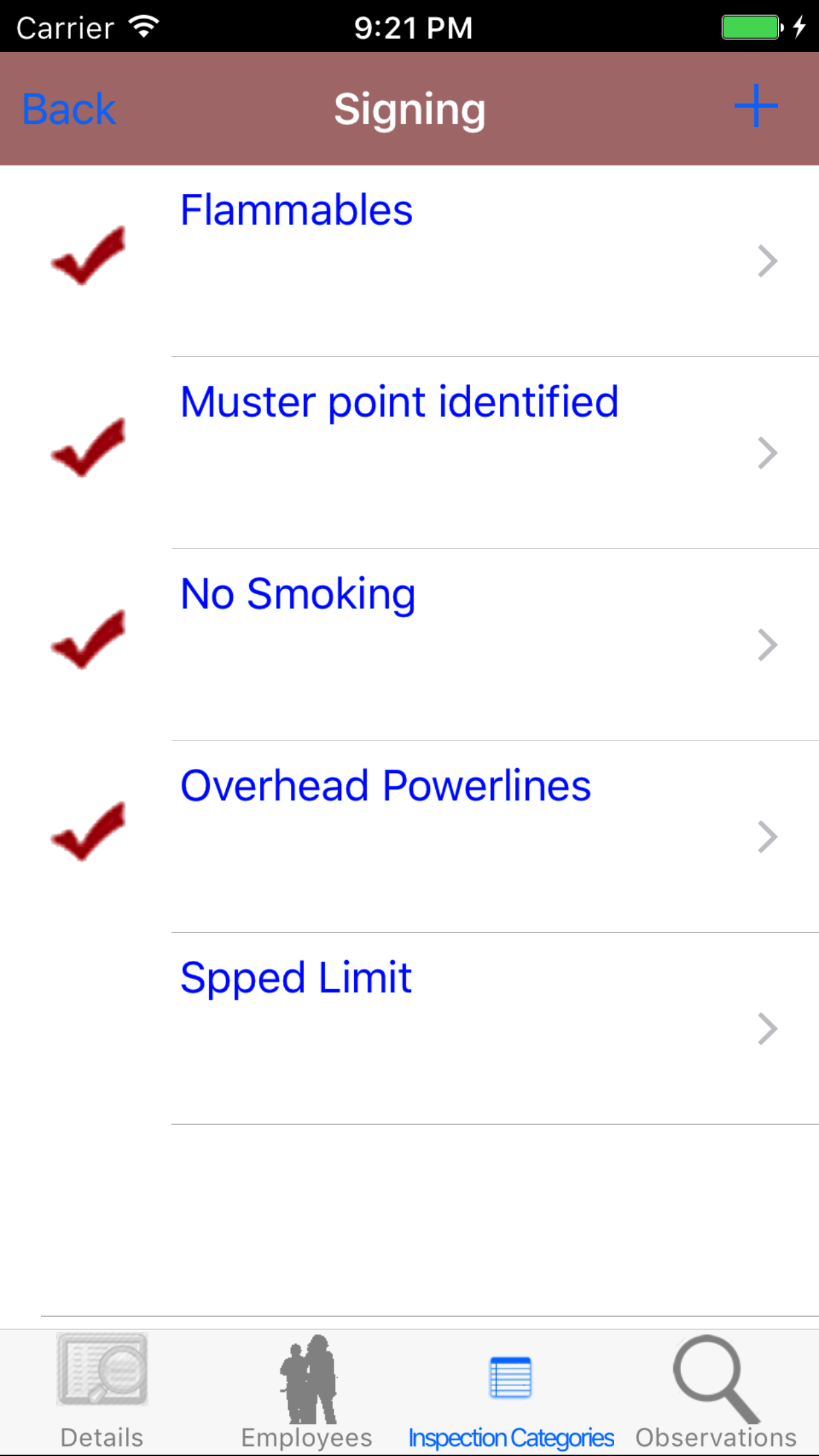

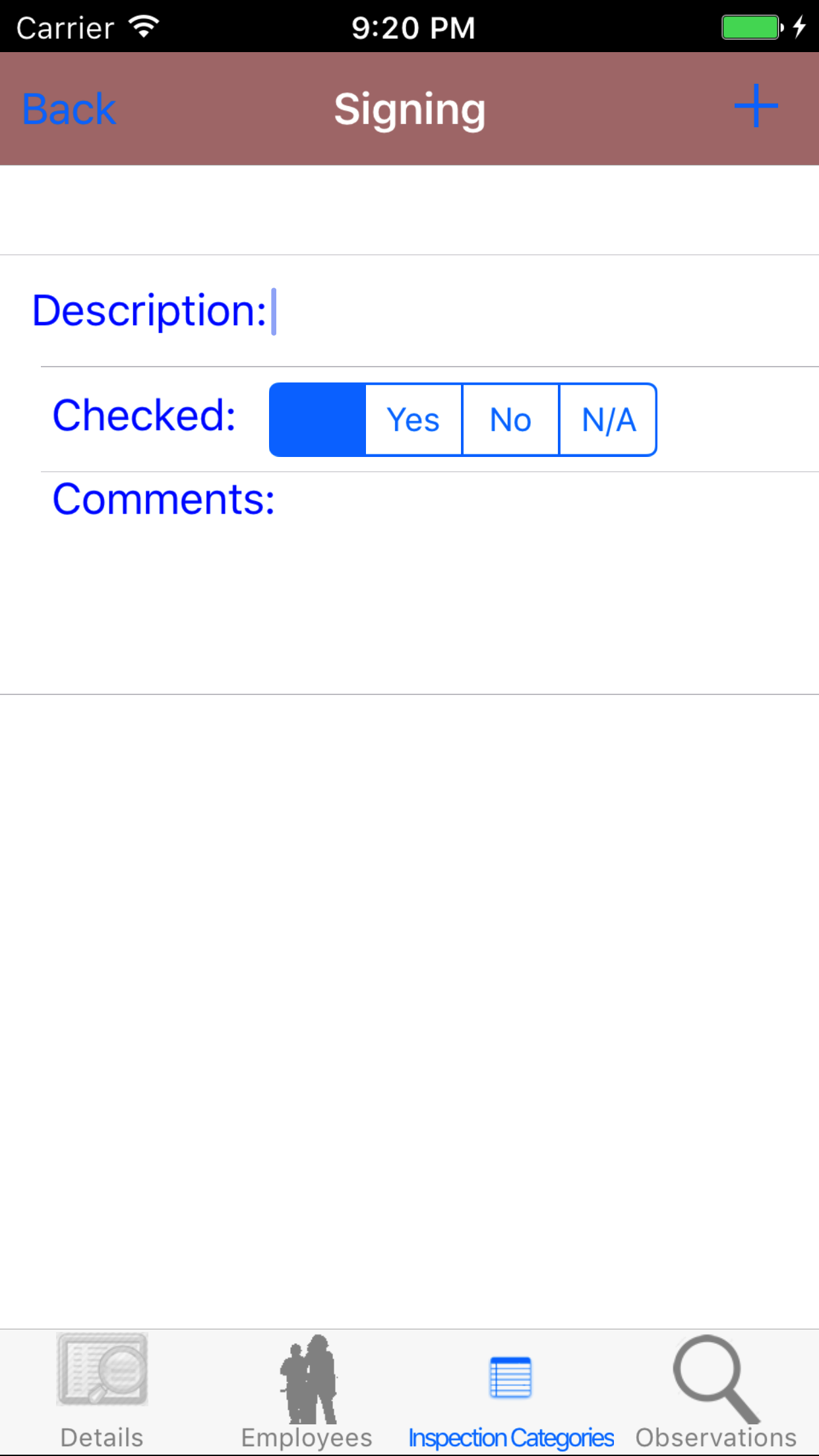

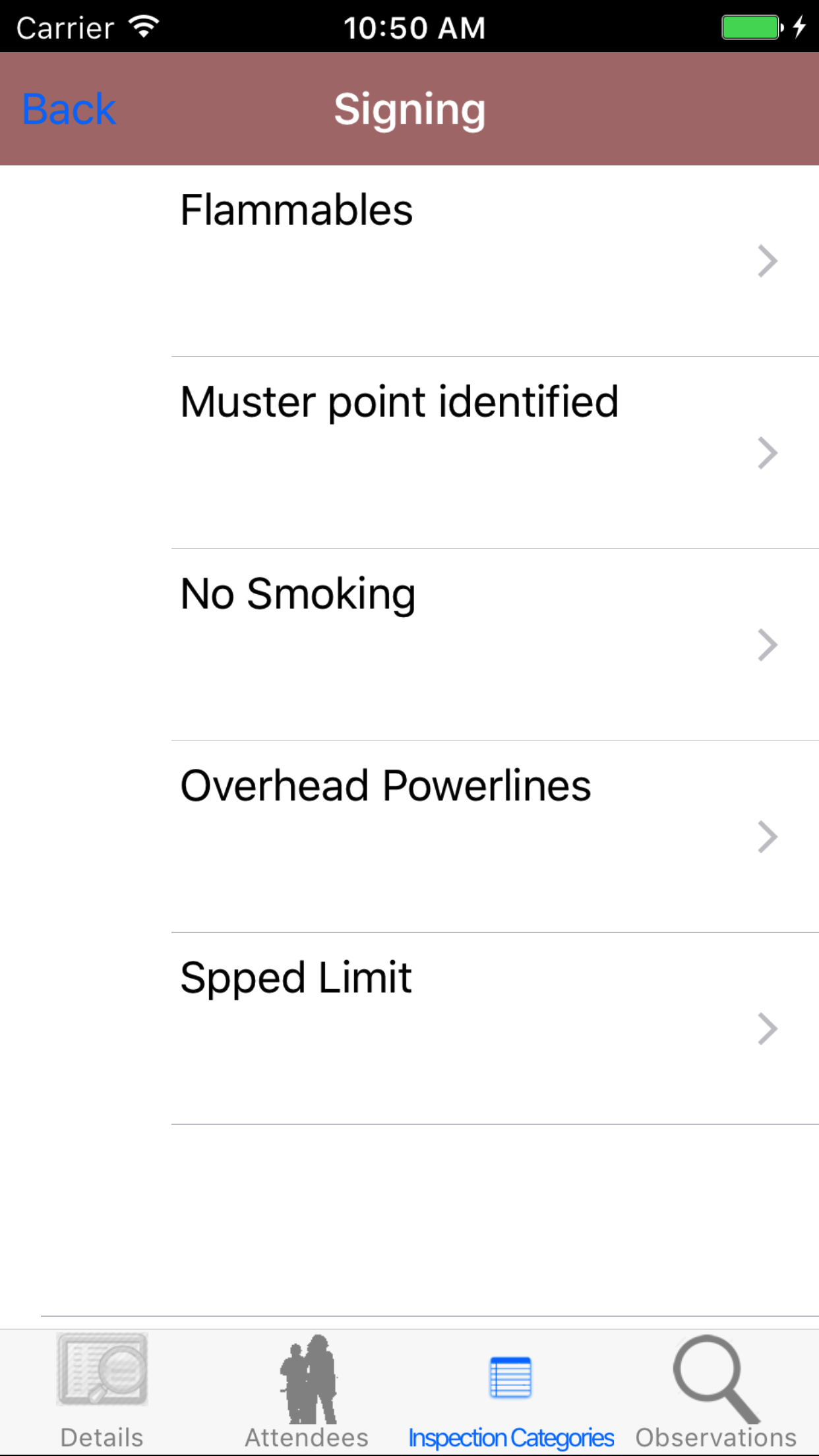

10.Edit Signing Inspection Checklist |

|

Signing Inspection Tasks are vehicle inspection signing inspection tasks that a company has set up for their field staff to complete

as part of their safety inspection. To ensure field staff have the most up to date copy of the inspection tasks a company is

using make sure to update your phone on a regular basis. For more information about updating your phone click here.

Once on the Safety Inspection you would like to Edit

Steps

- Tap the Inspection Categories icon at the bottom of the screen to open the Inspection Categories Checklist screen. The screen loads

with the list of the 6 checklist categories of the safety inspection.

- Tap the Signing button which loads with the signing inspection tasks listed with Task Name

in blue, with the Deficiencies or Comments in red. A Checked icon will appear depending on the value of the checked flag for each inspection task

if the checked value is set to Yes, a Checkmark will appear, if the checked value is set to No, a X will appear and if the checked value is set to N/A a N/A will appear.

- Scroll the list of tasks until the desired task is displayed on the screen.

- Tap on the Task, which will load the Edit Inspection Task screen.

The next screen loads with the Description of the task at the top of the screen and the ability to change the checked

status and deficiency or comment field.

Fields

- Checked: Tap __|Sat.|Req.|N/A to change the status of the inspection task.

- __: means task has not been checked.

- Sat.: means inspection tasks has been found to be satisfactory.

- Req.: means inspection tasks has been found to be requires attention. Any task marked as Req. requires a description

of the issue to be written in the deficiency or comments field.

- N/A: means inspection tasks is not applicable to the safety inspection.

- Deficiency or Comments: The Deficiency or Comments field gives the user the ability to describe the issues found with the

subject of the the inspection task. The user should enter a description or a comment about the problem found. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the signing inspection task details

|

|

| Step 1 |

|

|

| Steps 2-3 |

|

|

| Steps 4-6 |

|

|

|

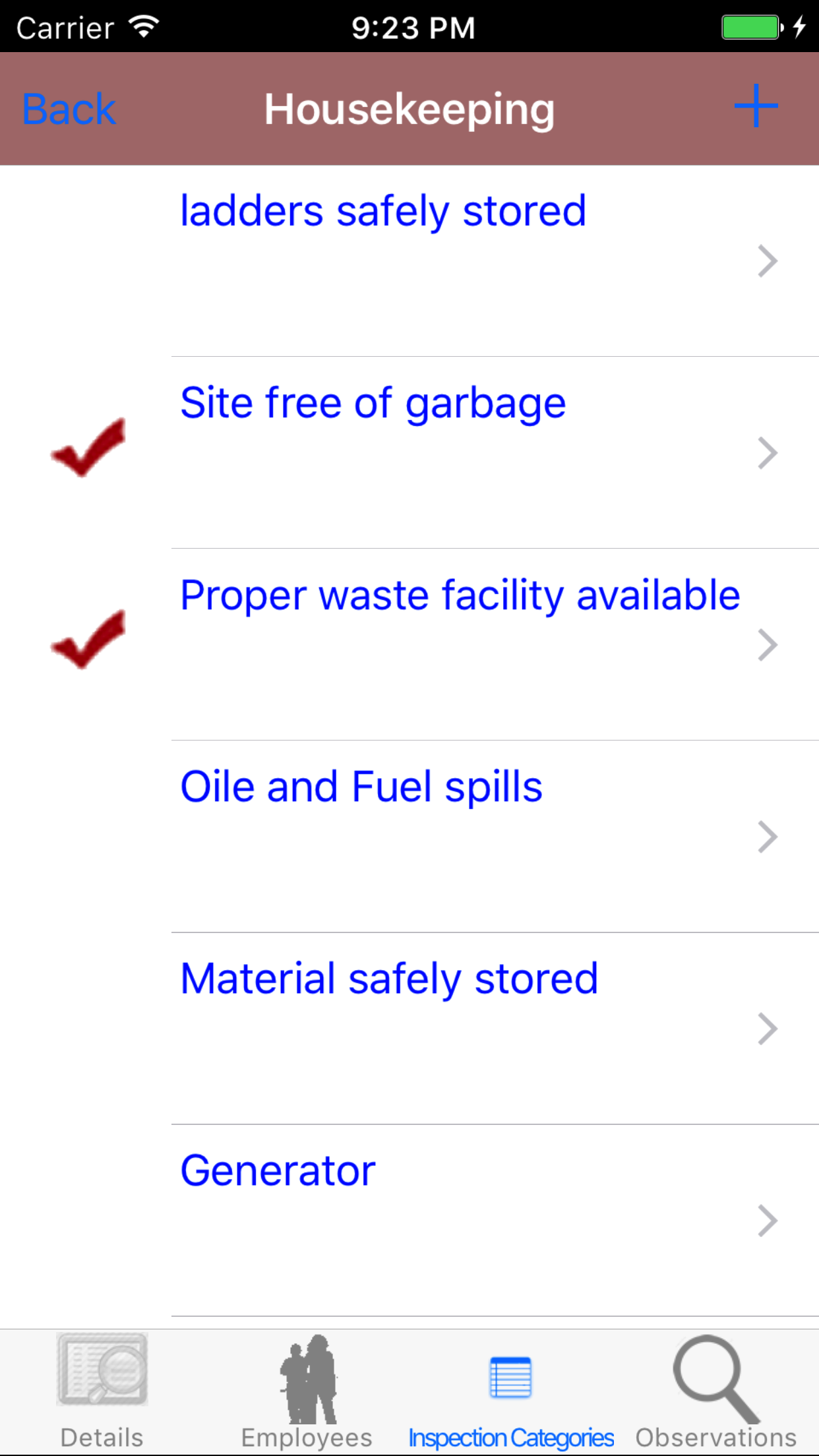

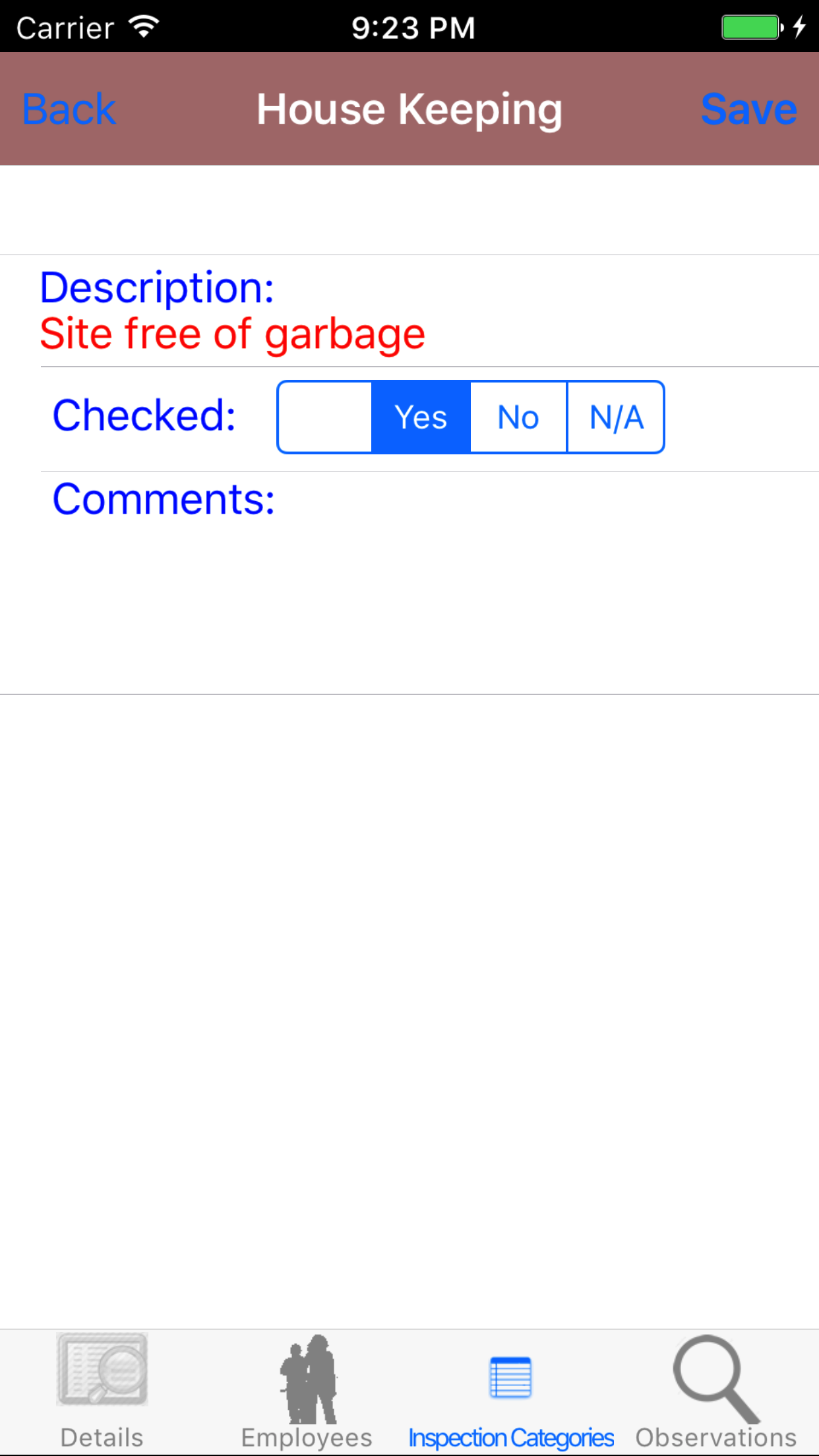

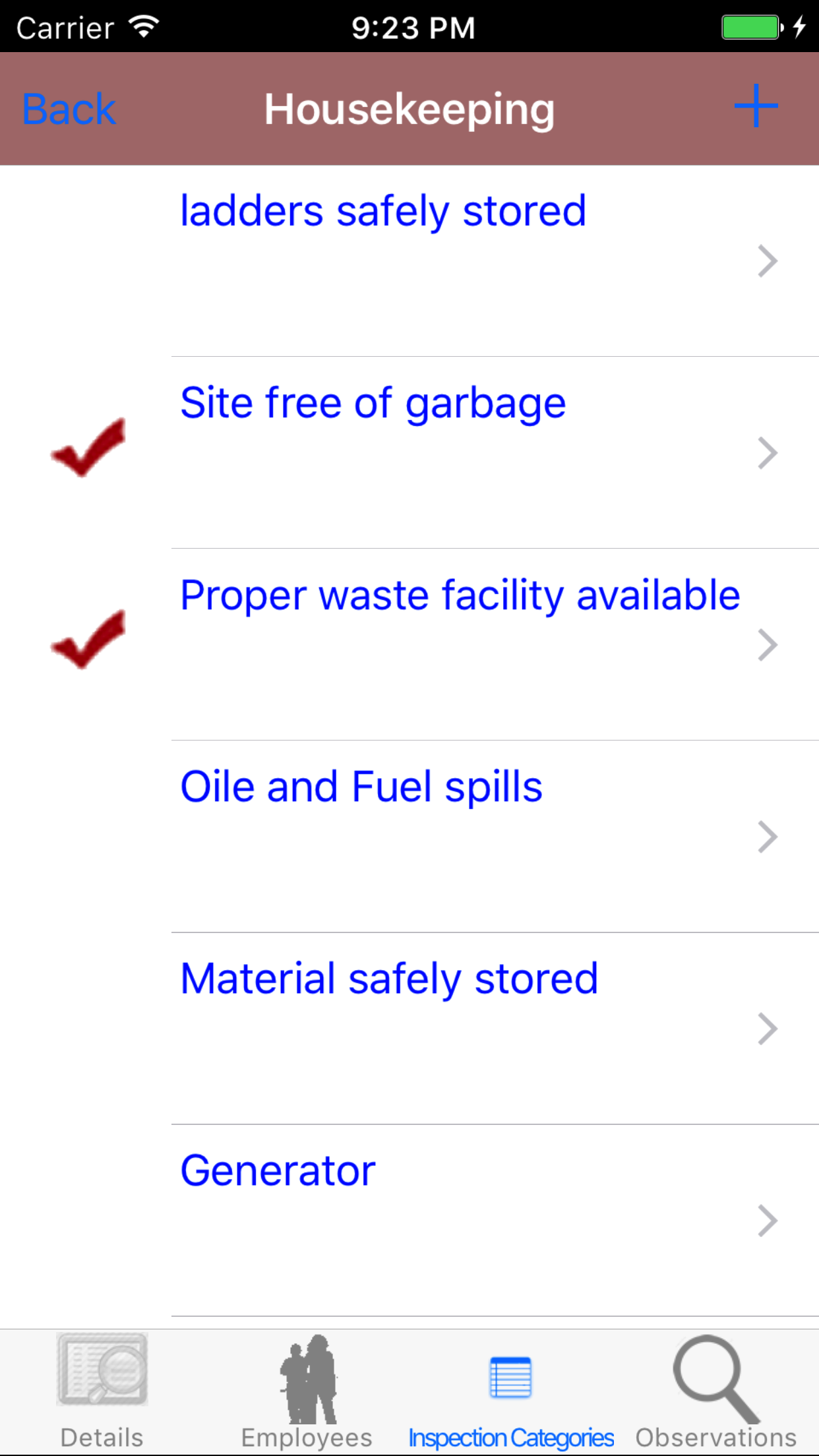

11.Edit Housekeeping Inspection Checklist |

|

Housekeeping Inspection Tasks are safety inspection housekeeping inspection tasks that a company has set up for their field staff to complete

as part of their safety inspection. To ensure field staff have the most up to date copy of the inspection tasks a company is

using make sure to update your phone on a regular basis. For more information about updating your phone click here.

Once on the Safety Inspection you would like to Edit

Steps

- Tap the Inspection Categories icon at the bottom of the screen to open the Inspection Categories Checklist screen. The screen loads

with the list of the 6 checklist categories of the safety inspection.

- Tap the Housekeeping button which loads with the housekeeping inspection tasks listed with Task Name

in blue, with the Deficiencies or Comments in red. A Checked icon will appear depending on the value of the checked flag for each inspection task

if the checked value is set to Yes, a Checkmark will appear, if the checked value is set to No, a X will appear and if the checked value is set to N/A a N/A will appear.

- Scroll the list of tasks until the desired task is displayed on the screen.

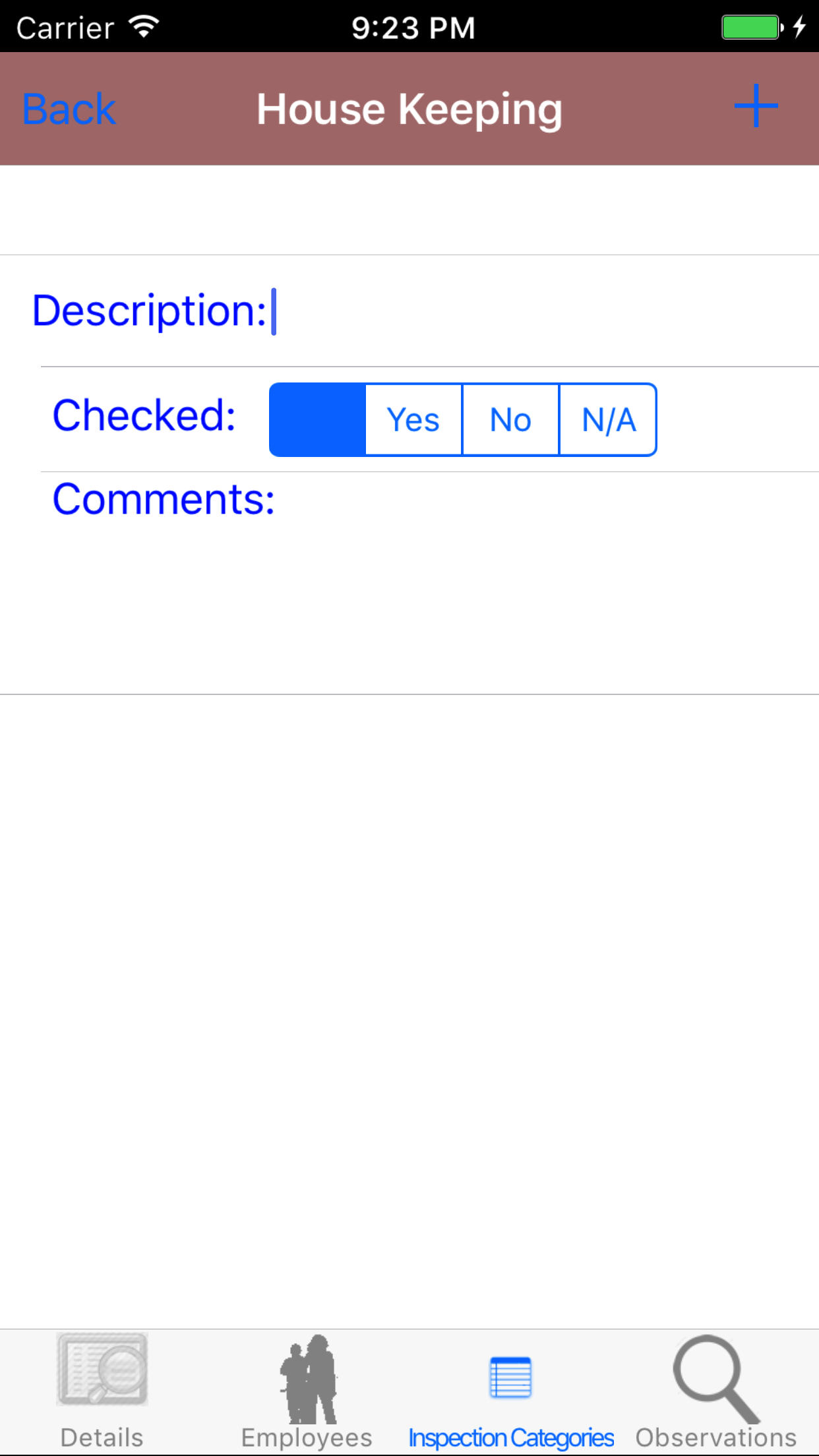

- Tap on the Task, which will load the Edit Inspection Task screen.

The next screen loads with the Description of the task at the top of the screen and the ability to change the checked

status and deficiency or comment field.

Fields

- Checked: Tap __|Sat.|Req.|N/A to change the status of the inspection task.

- __: means task has not been checked.

- Sat.: means inspection tasks has been found to be satisfactory.

- Req.: means inspection tasks has been found to be requires attention. Any task marked as Req. requires a description

of the issue to be written in the deficiency or comments field.

- N/A: means inspection tasks is not applicable to the safety inspection.

- Deficiency or Comments: The Deficiency or Comments field gives the user the ability to describe the issues found with the

subject of the the inspection task. The user should enter a description or a comment about the problem found. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the housekeeping inspection task details

|

|

| Step 1 |

|

|

| Steps 2-3 |

|

|

| Steps 4-6 |

|

|

|

12.Edit Safety Inspection Checklist |

|

Safety Inspection Tasks are safety inspection safety inspection tasks that a company has set up for their field staff to complete

as part of their safety inspection. To ensure field staff have the most up to date copy of the inspection tasks a company is

using make sure to update your phone on a regular basis. For more information about updating your phone click here.

Once on the Safety Inspection you would like to Edit

Steps

- Tap the Inspection Categories icon at the bottom of the screen to open the Inspection Categories Checklist screen. The screen loads

with the list of the 6 checklist categories of the safety inspection.

- Tap the Safety button which loads with the safety inspection tasks listed with Task Name

in blue, with the Deficiencies or Comments in red. A Checked icon will appear depending on the value of the checked flag for each inspection task

if the checked value is set to Yes, a Checkmark will appear, if the checked value is set to No, a X will appear and if the checked value is set to N/A a N/A will appear.

- Scroll the list of tasks until the desired task is displayed on the screen.

- Tap on the Task, which will load the Edit Inspection Task screen.

The next screen loads with the Description of the task at the top of the screen and the ability to change the checked

status and deficiency or comment field.

Fields

- Checked: Tap __|Sat.|Req.|N/A to change the status of the inspection task.

- __: means task has not been checked.

- Sat.: means inspection tasks has been found to be satisfactory.

- Req.: means inspection tasks has been found to be requires attention. Any task marked as Req. requires a description

of the issue to be written in the deficiency or comments field.

- N/A: means inspection tasks is not applicable to the safety inspection.

- Deficiency or Comments: The Deficiency or Comments field gives the user the ability to describe the issues found with the

subject of the the inspection task. The user should enter a description or a comment about the problem found. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the safety inspection task details

|

|

| Step 1 |

|

|

| Steps 2-3 |

|

|

| Steps 4-6 |

|

|

|

13.Add Personal Protective Equipment Inspection Checklist |

|

Personal Protective Equipment Inspection Tasks are safety inspection personal protective equipment inspection tasks that a company has set up for their field staff to complete

as part of their safety inspection. To ensure field staff have the most up to date copy of the inspection tasks a company is

using make sure to update your phone on a regular basis. For more information about updating your phone click here.

Once on the Safety Inspection you would like to Edit

Steps

- Tap the Inspection Categories icon at the bottom of the screen to open the Inspection Categories Checklist screen. The screen loads

with the list of the 6 checklist categories of the safety inspection.

- Tap the Personal Protective Equipment button which loads with the personal protective equipment inspection tasks listed with Task Name

in blue, with the Deficiencies or Comments in red. A Checked icon will appear depending on the value of the checked flag for each inspection task

if the checked value is set to Yes, a Checkmark will appear, if the checked value is set to No, a X will appear and if the checked value is set to N/A a N/A will appear.

- Tap on the + in the top right corner, which will load the Add Inspection Task screen.

The next screen loads with the Description of the task at the top of the screen and the ability to change the checked

status and deficiency or comment field.

Fields

- Description: The Description field gives the user the ability to describe the task. The character limit of this field is 50.

- Checked: Tap __|Sat.|Req.|N/A to change the status of the inspection task.

- __: means task has not been checked.

- Sat.: means inspection tasks has been found to be satisfactory.

- Req.: means inspection tasks has been found to be requires attention. Any task marked as Req. requires a description

of the issue to be written in the deficiency or comments field.

- N/A: means inspection tasks is not applicable to the safety inspection.

- Deficiency or Comments: The Deficiency or Comments field gives the user the ability to describe the issues found with the

subject of the the inspection task. The user should enter a description or a comment about the problem found. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the personal protective equipment inspection task details

|

|

| Step 1 |

|

|

| Steps 2-3 |

|

|

| Steps 4-6 |

|

|

|

14.Add Mobile Equipment Inspection Checklist |

|

Mobile Equipment Tasks are safety inspection mobile equipment inspection tasks that a company has set up for their field staff to complete

as part of their safety inspection. To ensure field staff have the most up to date copy of the inspection tasks a company is

using make sure to update your phone on a regular basis. For more information about updating your phone click here.

Once on the Vehicle Inspection you would like to Edit

Steps

- Tap the Inspection Categories icon at the bottom of the screen to open the Inspection Categories Checklist screen. The screen loads

with the list of the 6 checklist categories of the safety inspection.

- Tap the Mobile Equipment button which loads with the mobile equipment inspection tasks listed with Task Name

in blue, with the Deficiencies or Comments in red. A Checked icon will appear depending on the value of the checked flag for each inspection task

if the checked value is set to Yes, a Checkmark will appear, if the checked value is set to No, a X will appear and if the checked value is set to N/A a N/A will appear.

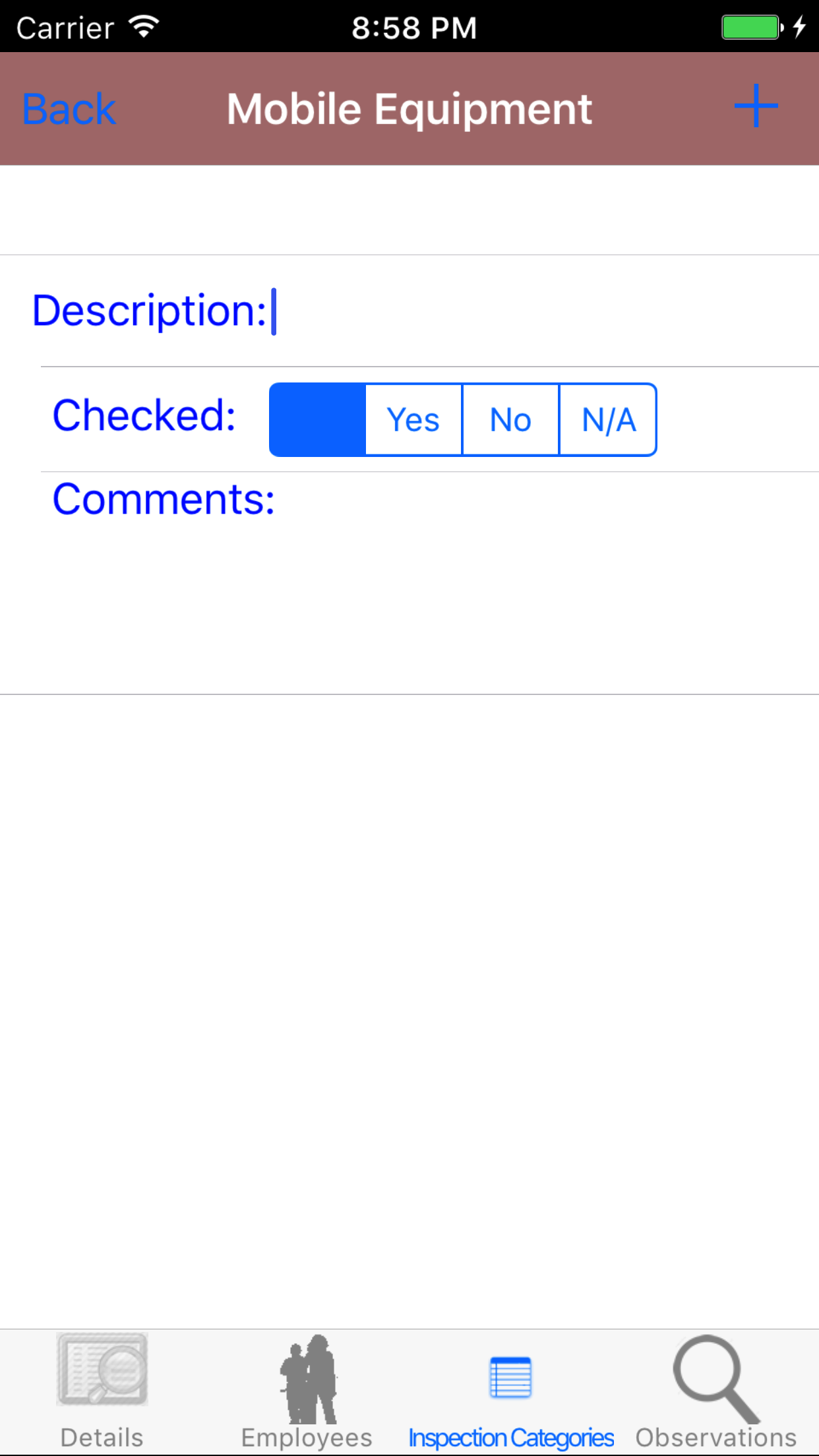

- Tap on the + in the top right corner, which will load the Add Inspection Task screen.

The next screen loads with the Description of the task at the top of the screen and the ability to change the checked

status and deficiency or comment field.

Fields

- Description: The Description field gives the user the ability to describe the task. The character limit of this field is 50.

- Checked: Tap __|Sat.|Req.|N/A to change the status of the inspection task.

- __: means task has not been checked.

- Sat.: means inspection tasks has been found to be satisfactory.

- Req.: means inspection tasks has been found to be requires attention. Any task marked as Req. requires a description

of the issue to be written in the deficiency or comments field.

- N/A: means inspection tasks is not applicable to the safety inspection.

- Deficiency or Comments: The Deficiency or Comments field gives the user the ability to describe the issues found with the

subject of the the inspection task. The user should enter a description or a comment about the problem found. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the mobile equipment inspection task details

|

|

| Step 1 |

|

|

| Steps 2-3 |

|

|

| Steps 4-6 |

|

|

|

15.Add Condition of Hand Tools Inspection Checklist |

|

Condition of Hand Tools Inspection Tasks are vehicle inspection condition of hand tools inspection tasks that a company has set up for their field staff to complete

as part of their safety inspection. To ensure field staff have the most up to date copy of the inspection tasks a company is

using make sure to update your phone on a regular basis. For more information about updating your phone click here.

Once on the Safety Inspection you would like to Edit

Steps

- Tap the Inspection Categories icon at the bottom of the screen to open the Inspection Categories Checklist screen. The screen loads

with the list of the 6 checklist categories of the safety inspection.

- Tap the Condition of Hand Tools button which loads with the condition of hand tools inspection tasks listed with Task Name

in blue, with the Deficiencies or Comments in red. A Checked icon will appear depending on the value of the checked flag for each inspection task

if the checked value is set to Yes, a Checkmark will appear, if the checked value is set to No, a X will appear and if the checked value is set to N/A a N/A will appear.

- Tap on the + in the top right corner, which will load the Add Inspection Task screen.

The next screen loads with the Description of the task at the top of the screen and the ability to change the checked

status and deficiency or comment field.

Fields

- Description: The Description field gives the user the ability to describe the task. The character limit of this field is 50.

- Checked: Tap __|Sat.|Req.|N/A to change the status of the inspection task.

- __: means task has not been checked.

- Sat.: means inspection tasks has been found to be satisfactory.

- Req.: means inspection tasks has been found to be requires attention. Any task marked as Req. requires a description

of the issue to be written in the deficiency or comments field.

- N/A: means inspection tasks is not applicable to the safety inspection.

- Deficiency or Comments: The Deficiency or Comments field gives the user the ability to describe the issues found with the

subject of the the inspection task. The user should enter a description or a comment about the problem found. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the condition of hand tools inspection task details

|

|

| Steps 1-3 |

|

|

| Steps 4-6 |

|

|

|

16.Add Signing Inspection Checklist |

|

Signing Inspection Tasks are vehicle inspection signing inspection tasks that a company has set up for their field staff to complete

as part of their safety inspection. To ensure field staff have the most up to date copy of the inspection tasks a company is

using make sure to update your phone on a regular basis. For more information about updating your phone click here.

Once on the Safety Inspection you would like to Edit

Steps

- Tap the Inspection Categories icon at the bottom of the screen to open the Inspection Categories Checklist screen. The screen loads

with the list of the 6 checklist categories of the safety inspection.

- Tap the Signing button which loads with the signing inspection tasks listed with Task Name

in blue, with the Deficiencies or Comments in red. A Checked icon will appear depending on the value of the checked flag for each inspection task

if the checked value is set to Yes, a Checkmark will appear, if the checked value is set to No, a X will appear and if the checked value is set to N/A a N/A will appear.

- Tap on the + in the top right corner, which will load the Add Inspection Task screen.

The next screen loads with the Description of the task at the top of the screen and the ability to change the checked

status and deficiency or comment field.

Fields

- Description: The Description field gives the user the ability to describe the task. The character limit of this field is 50.

- Checked: Tap __|Sat.|Req.|N/A to change the status of the inspection task.

- __: means task has not been checked.

- Sat.: means inspection tasks has been found to be satisfactory.

- Req.: means inspection tasks has been found to be requires attention. Any task marked as Req. requires a description

of the issue to be written in the deficiency or comments field.

- N/A: means inspection tasks is not applicable to the safety inspection.

- Deficiency or Comments: The Deficiency or Comments field gives the user the ability to describe the issues found with the

subject of the the inspection task. The user should enter a description or a comment about the problem found. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the signing inspection task details

|

|

| Step 1 |

|

|

| Steps 2-3 |

|

|

| Steps 4-6 |

|

|

|

17.Add Housekeeping Inspection Checklist |

|

Housekeeping Inspection Tasks are safety inspection housekeeping inspection tasks that a company has set up for their field staff to complete

as part of their safety inspection. To ensure field staff have the most up to date copy of the inspection tasks a company is

using make sure to update your phone on a regular basis. For more information about updating your phone click here.

Once on the Safety Inspection you would like to Edit

Steps

- Tap the Inspection Categories icon at the bottom of the screen to open the Inspection Categories Checklist screen. The screen loads

with the list of the 6 checklist categories of the safety inspection.

- Tap the Housekeeping button which loads with the housekeeping inspection tasks listed with Task Name

in blue, with the Deficiencies or Comments in red. A Checked icon will appear depending on the value of the checked flag for each inspection task

if the checked value is set to Yes, a Checkmark will appear, if the checked value is set to No, a X will appear and if the checked value is set to N/A a N/A will appear.

- Tap on the + in the top right corner, which will load the Add Inspection Task screen.

The next screen loads with the Description of the task at the top of the screen and the ability to change the checked

status and deficiency or comment field.

Fields

- Description: The Description field gives the user the ability to describe the task. The character limit of this field is 50.

- Checked: Tap __|Sat.|Req.|N/A to change the status of the inspection task.

- __: means task has not been checked.

- Sat.: means inspection tasks has been found to be satisfactory.

- Req.: means inspection tasks has been found to be requires attention. Any task marked as Req. requires a description

of the issue to be written in the deficiency or comments field.

- N/A: means inspection tasks is not applicable to the safety inspection.

- Deficiency or Comments: The Deficiency or Comments field gives the user the ability to describe the issues found with the

subject of the the inspection task. The user should enter a description or a comment about the problem found. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the housekeeping inspection task details

|

|

| Step 1 |

|

|

| Steps 2-3 |

|

|

| Steps 4-6 |

|

|

|

18.Add Safety Inspection Checklist |

|

Safety Inspection Tasks are safety inspection safety inspection tasks that a company has set up for their field staff to complete

as part of their safety inspection. To ensure field staff have the most up to date copy of the inspection tasks a company is

using make sure to update your phone on a regular basis. For more information about updating your phone click here.

Once on the Safety Inspection you would like to Edit

Steps

- Tap the Inspection Categories icon at the bottom of the screen to open the Inspection Categories Checklist screen. The screen loads

with the list of the 6 checklist categories of the safety inspection.

- Tap the Safety button which loads with the safety inspection tasks listed with Task Name

in blue, with the Deficiencies or Comments in red. A Checked icon will appear depending on the value of the checked flag for each inspection task

if the checked value is set to Yes, a Checkmark will appear, if the checked value is set to No, a X will appear and if the checked value is set to N/A a N/A will appear.

- Tap on the + in the top right corner, which will load the Add Inspection Task screen.

The next screen loads with the Description of the task at the top of the screen and the ability to change the checked

status and deficiency or comment field.

Fields

- Description: The Description field gives the user the ability to describe the task. The character limit of this field is 50.

- Checked: Tap __|Sat.|Req.|N/A to change the status of the inspection task.

- __: means task has not been checked.

- Sat.: means inspection tasks has been found to be satisfactory.

- Req.: means inspection tasks has been found to be requires attention. Any task marked as Req. requires a description

of the issue to be written in the deficiency or comments field.

- N/A: means inspection tasks is not applicable to the safety inspection.

- Deficiency or Comments: The Deficiency or Comments field gives the user the ability to describe the issues found with the

subject of the the inspection task. The user should enter a description or a comment about the problem found. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the safety inspection task details

|

|

| Step 1 |

|

|

| Steps 2-3 |

|

|

| Steps 4-6 |

|

|

|

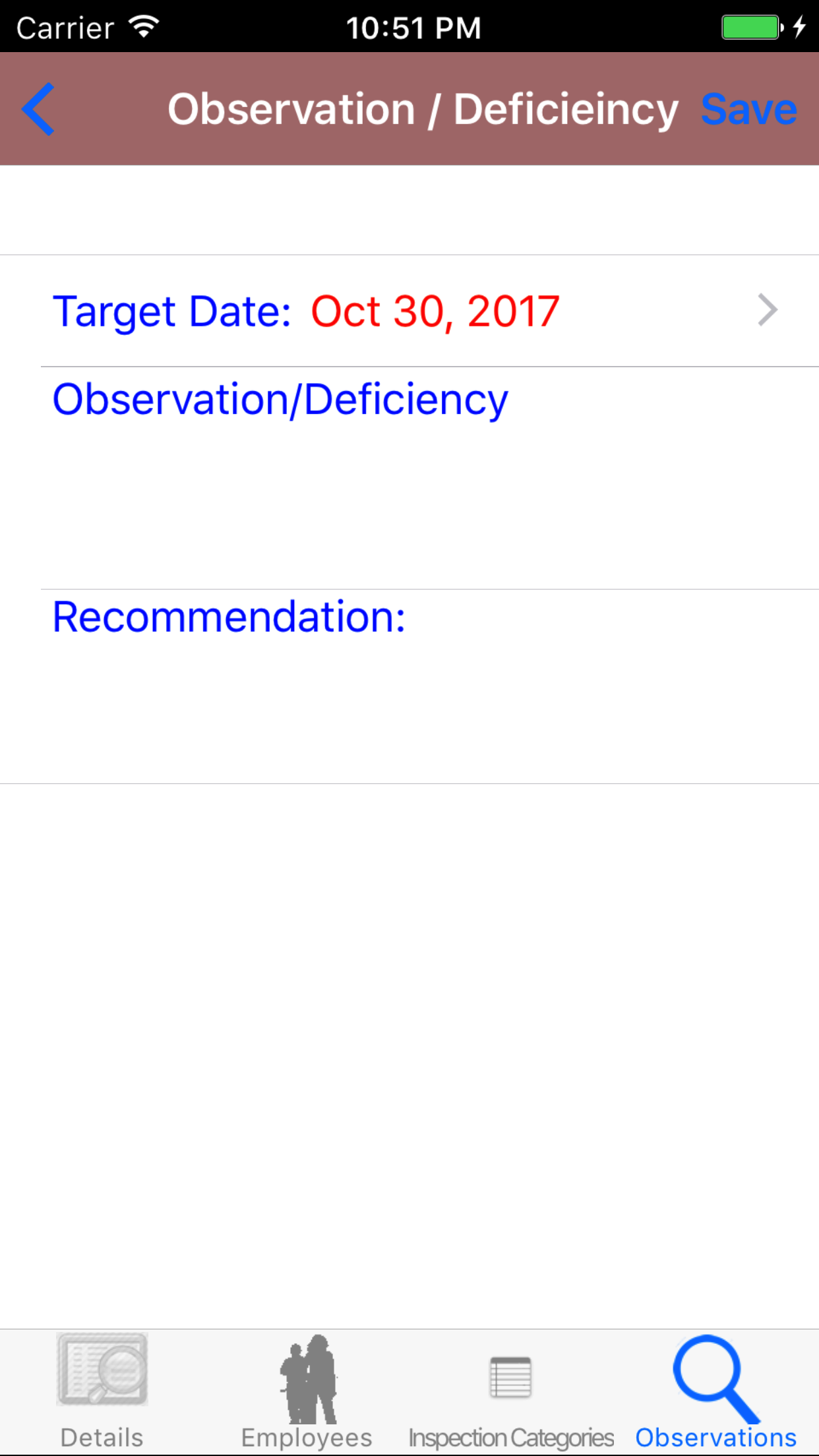

19.Add Observation |

|

Once on the Safety Inspection you would like to edit.

Steps

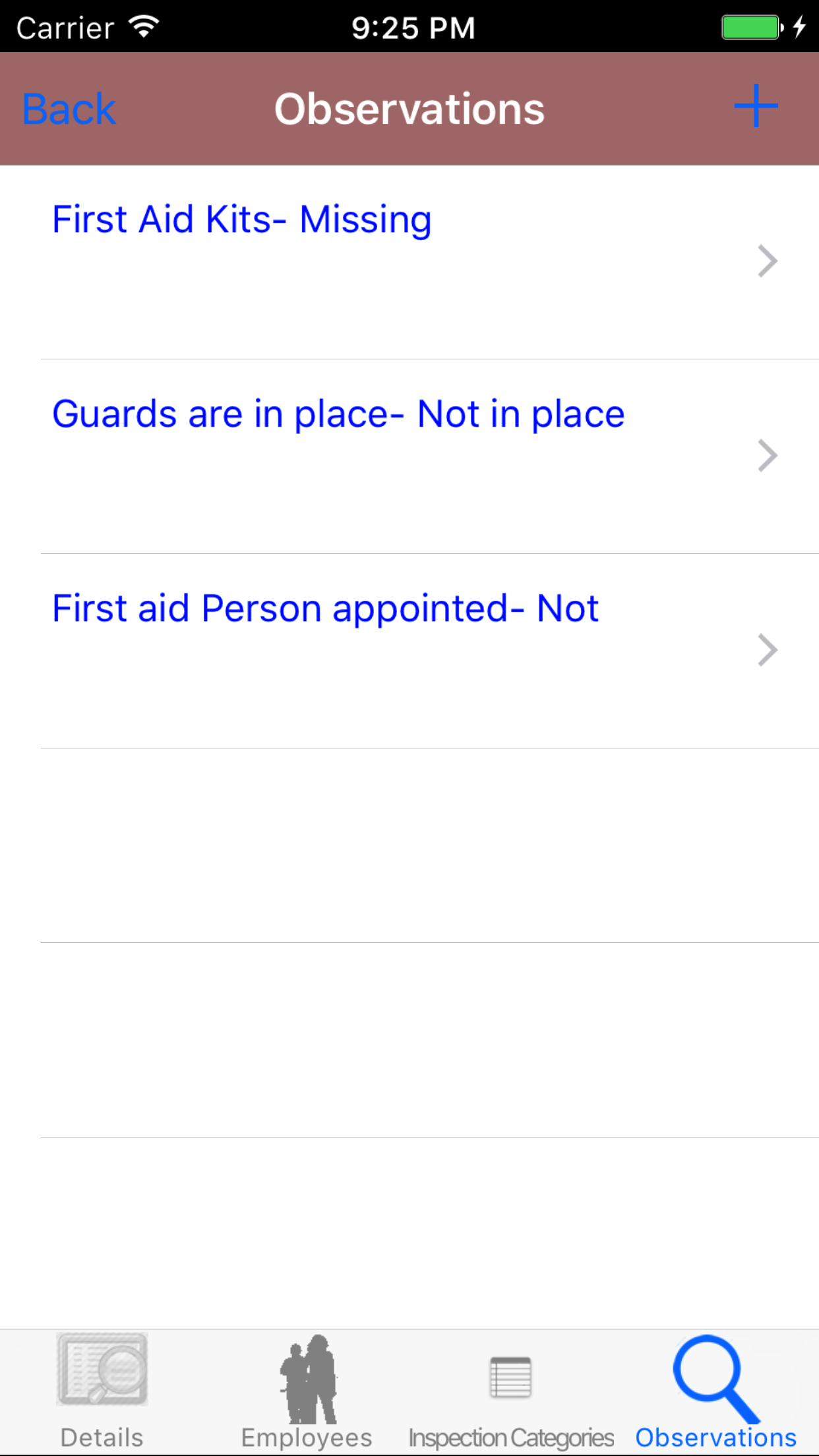

- Tap the Observation icon, the third tab. This opens the list of observations, observation/deficiency and recommendation in black text.

- Tap the + icon in the top right corner to load the add observation screen

Fields

- Target Date: The date field allow field staff to choose the date the issue should be resolved by.

- Tap the Date field to open the Choose Date screen.

- Scroll the date wheel on the far left of the screen until the desired date is highlighted.

- Return to the Add Observation screen by either tapping Save in the top right corner to select the highlighted date or tapping Cancel in the top left corner to leave the Date: field unchanged.

- Observation/Deficiency: The Observation/Deficiency field gives the user the ability to describe the issues found with the

during a safety inspection. The user should enter a description or a comment about the problem found. The character limit of this field is 250.

- Recommendation: The Recommendation field gives the user the ability to provide a recommendation to solve the observed problem. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the observation

|

|

|

| Steps 1-2 |

|

|

| Step 3 |

|

|

| Steps 4-6 |

|

|

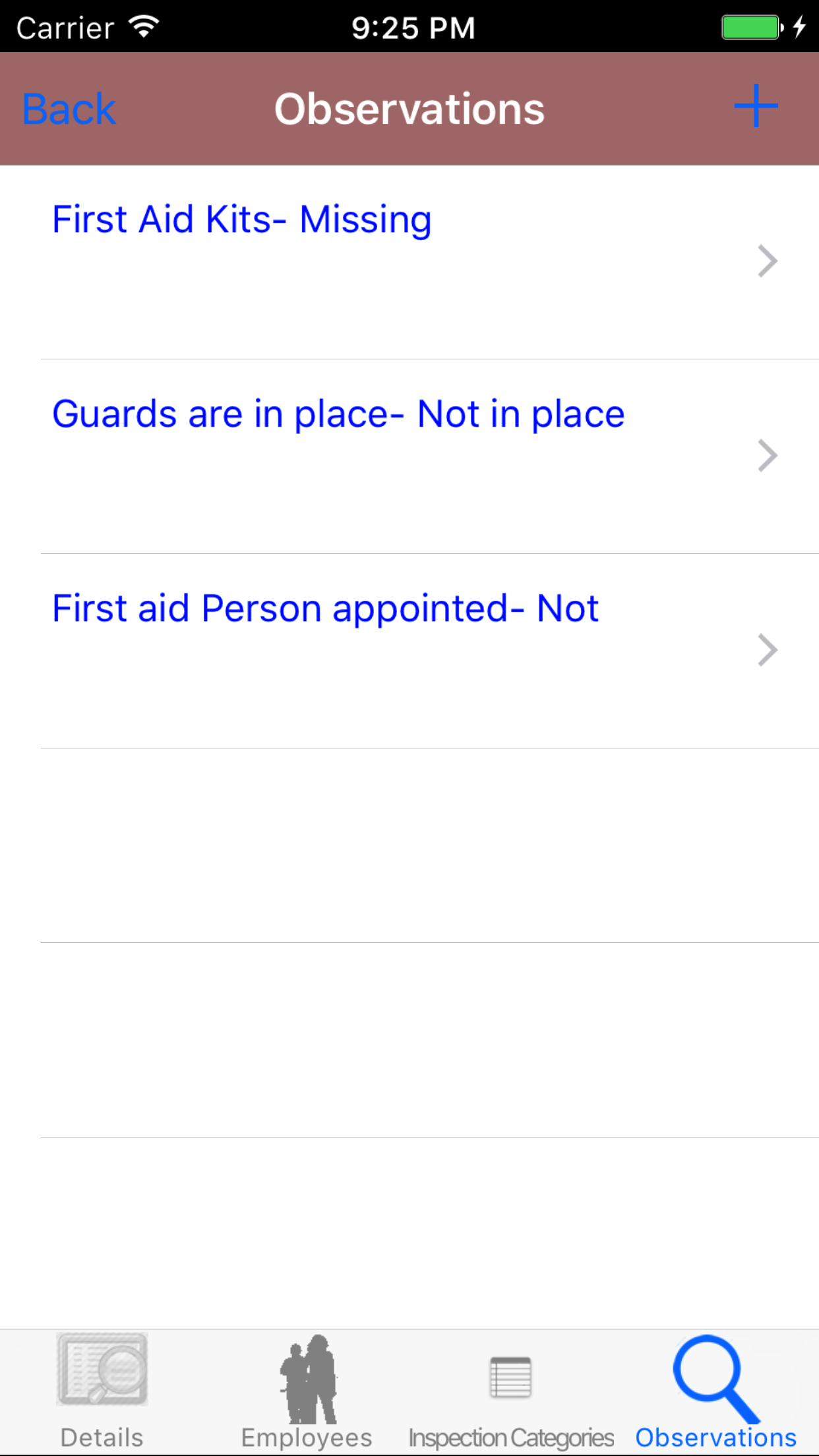

20.Look Up Observation |

|

Once on the Safety Inspection you would like to edit.

Steps

- Tap the Observation icon, the third tab. This opens the list of observations, observation/deficiency in red text and recommendation in blue text.

- Scroll the list of Observations until the desired Observation is displayed on the screen.

- Tap on the Observations you would like to view. This loads the observation edit screen.

|

|

| Steps 1-3 |

|

|

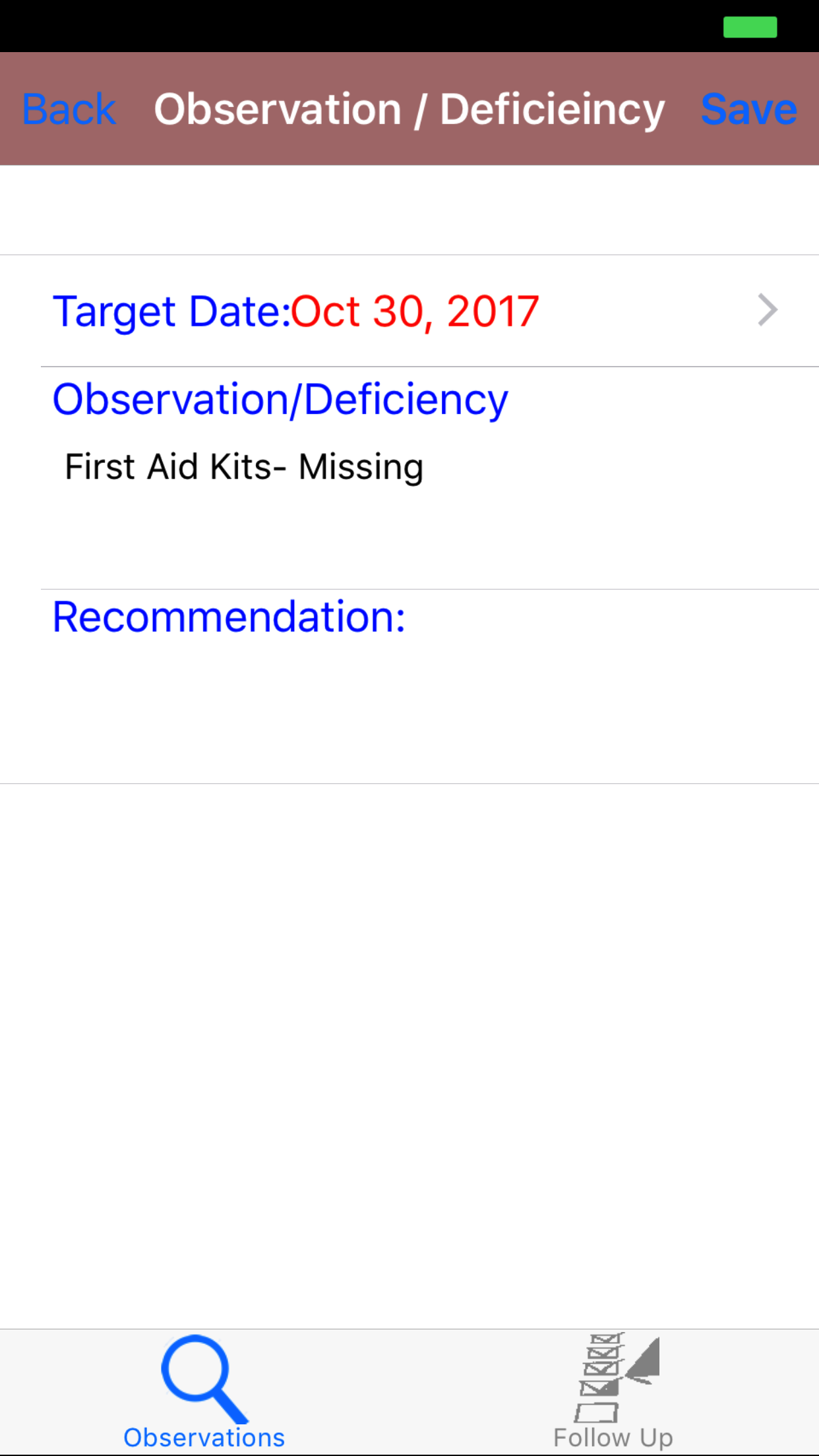

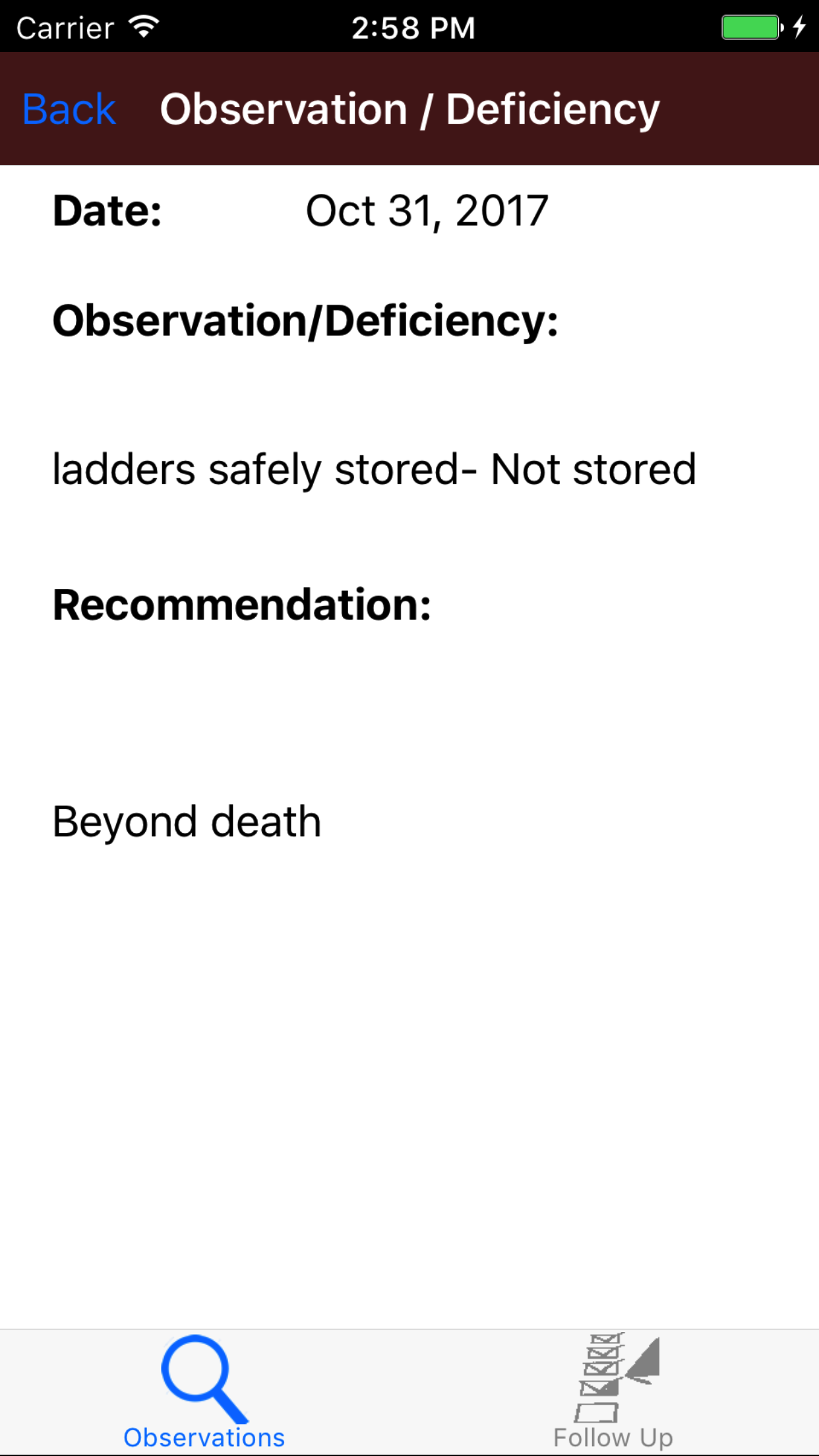

21.Edit Observation |

|

Once on the Observation edit screen

Fields

- Target Date: The date field allow field staff to choose the date the issue should be resolved by.

- Tap the Date field to open the Choose Date screen.

- Scroll the date wheel on the far left of the screen until the desired date is highlighted.

- Return to the Edit Observation screen by either tapping Save in the top right corner to select the highlighted date or tapping Cancel in the top left corner to leave the Date: field unchanged.

- Observation/Deficiency: The Observation/Deficiency field gives the user the ability to describe the issues found with the

during a safety inspection. The user should enter a description or a comment about the problem found. The character limit of this field is 250.

- Recommendation: The Recommendation field gives the user the ability to provide a recommendation to solve the observed problem. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the observation

|

|

| Steps 1-4 |

|

|

|

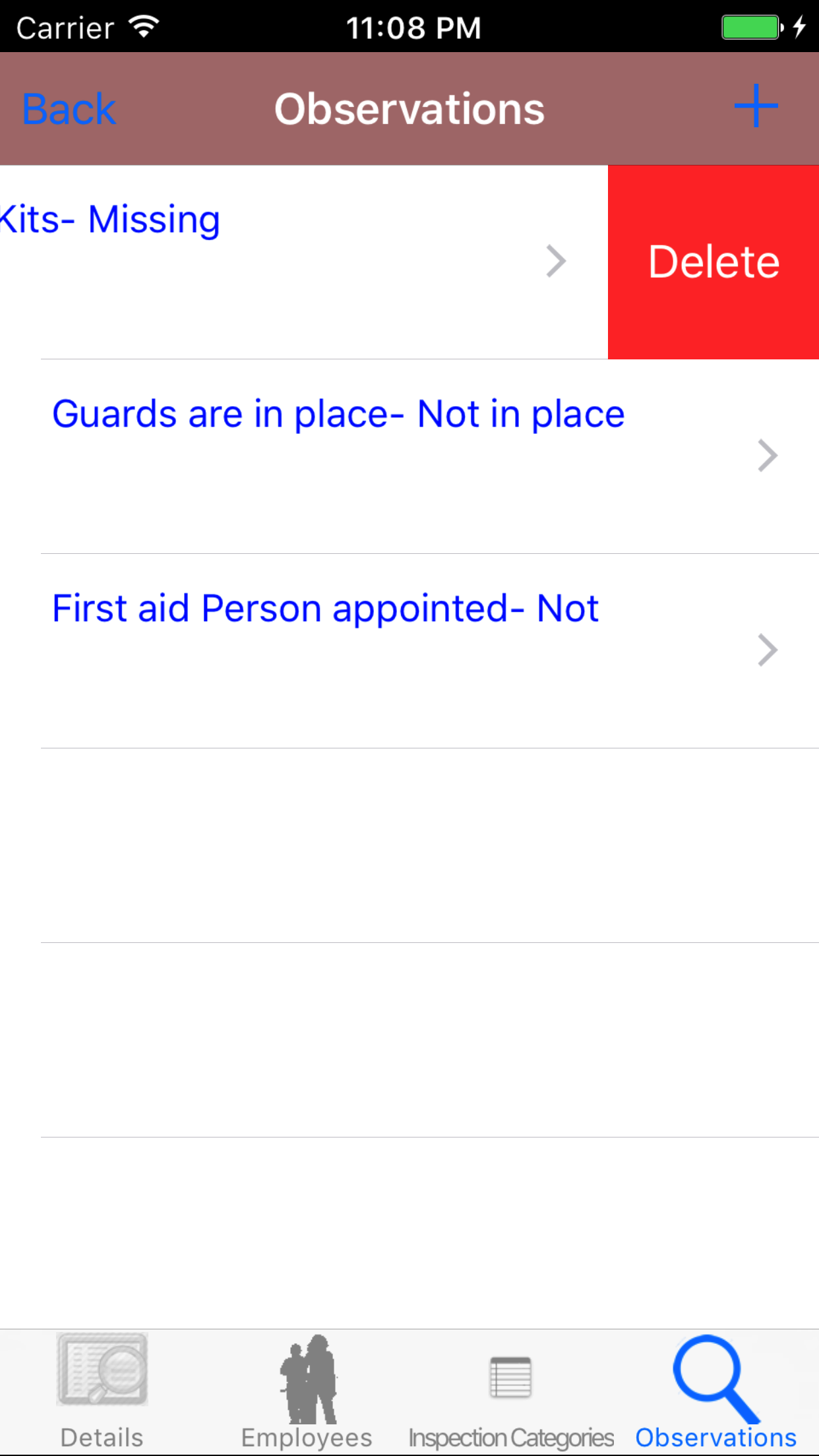

22.Delete Observation |

|

Once on the Safety Inspection you would like to edit.

Steps

- Tap the Observation icon, the third tab. This opens the list of observations, observation/deficiency in red text and recommendation in blue text.

- Scroll the list of Observations until the desired Observation is displayed on the screen.

- Swipe from the right edge to the left to bring up the delete button for the observation.

- Tap the Delete button. The observation will be deleted.

|

|

| Step 1 |

|

|

|

23.Add Follow Up |

|

Once on the Observation you would like to edit.

Steps

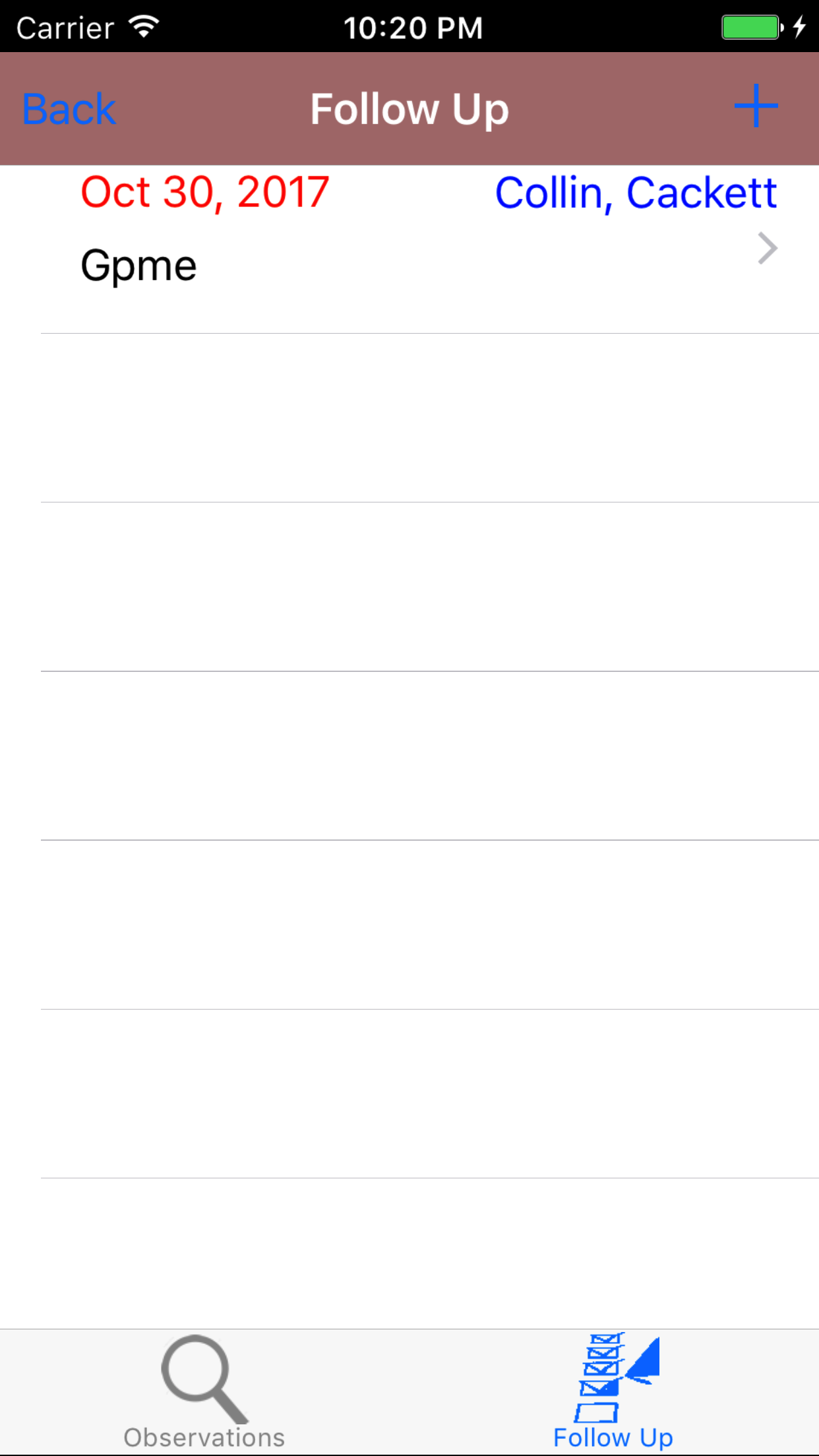

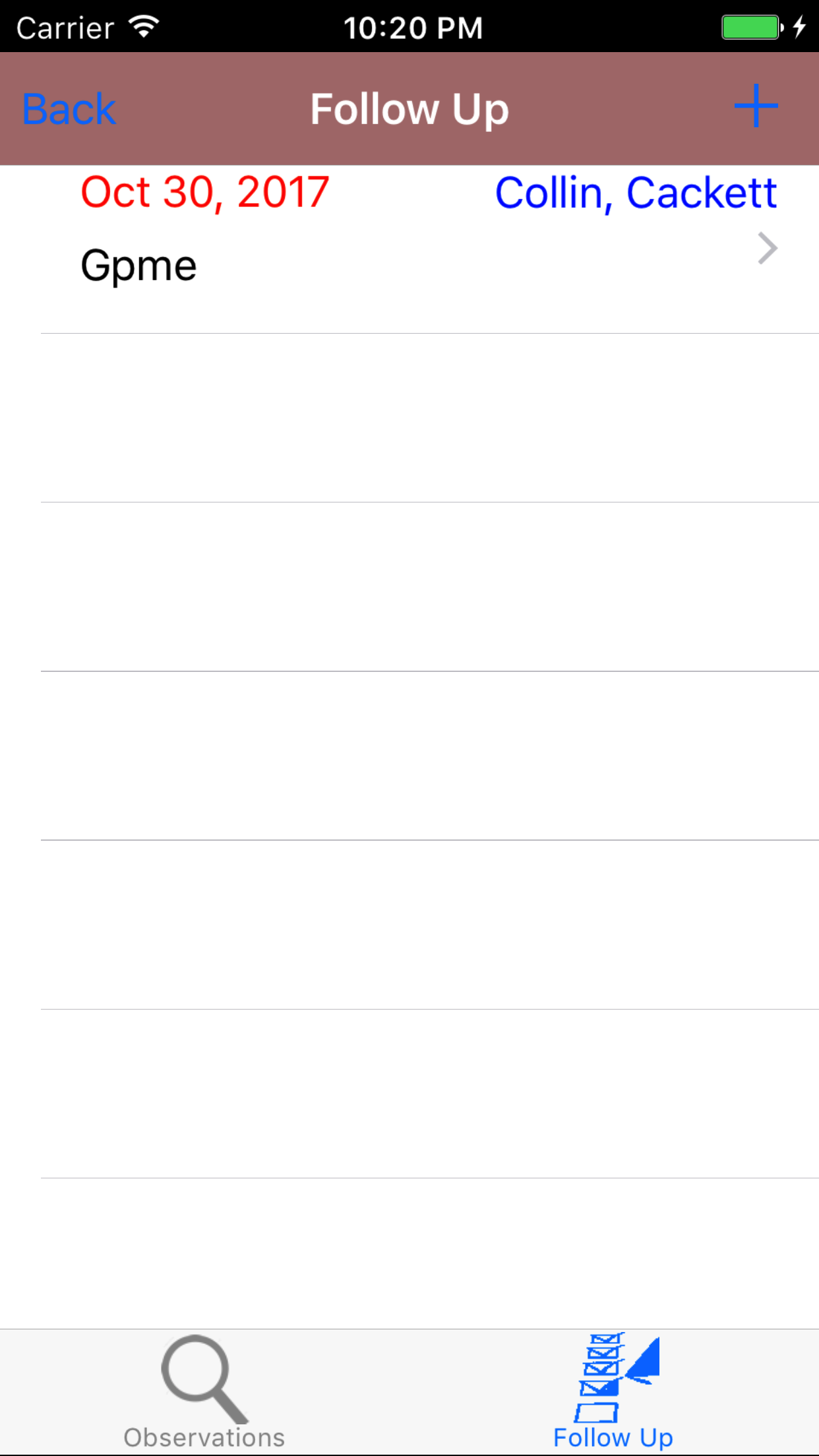

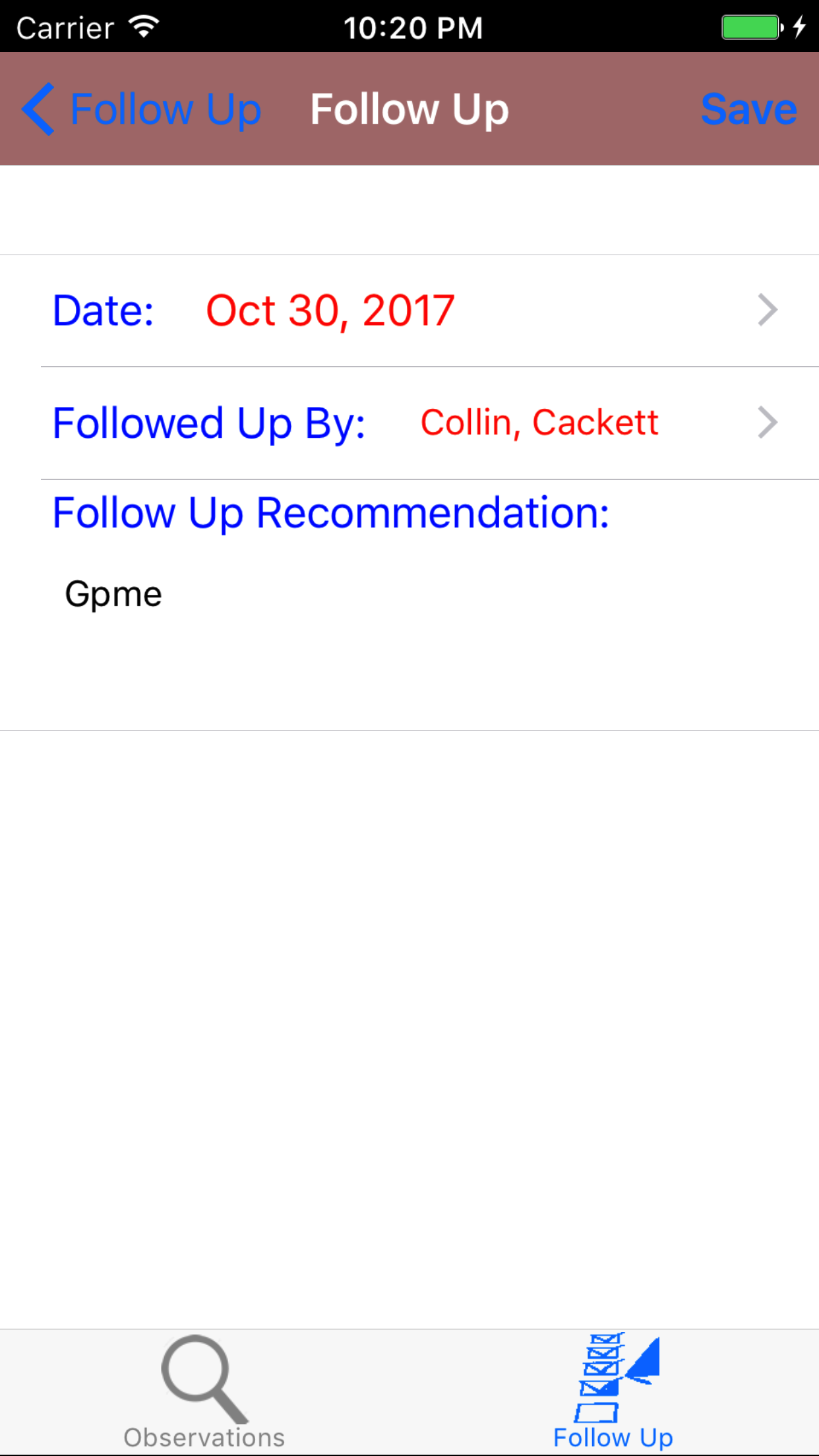

- Tap the Follow icon, the second tab. This opens the list of follows, follow up date in red text,

the employee who followed up in blue text and the description of the follow up in black text.

- Tap the + icon in the top right corner to load the add follow screen

Fields

- Date: The date field allow field staff to choose the date the issue should is resolved by.

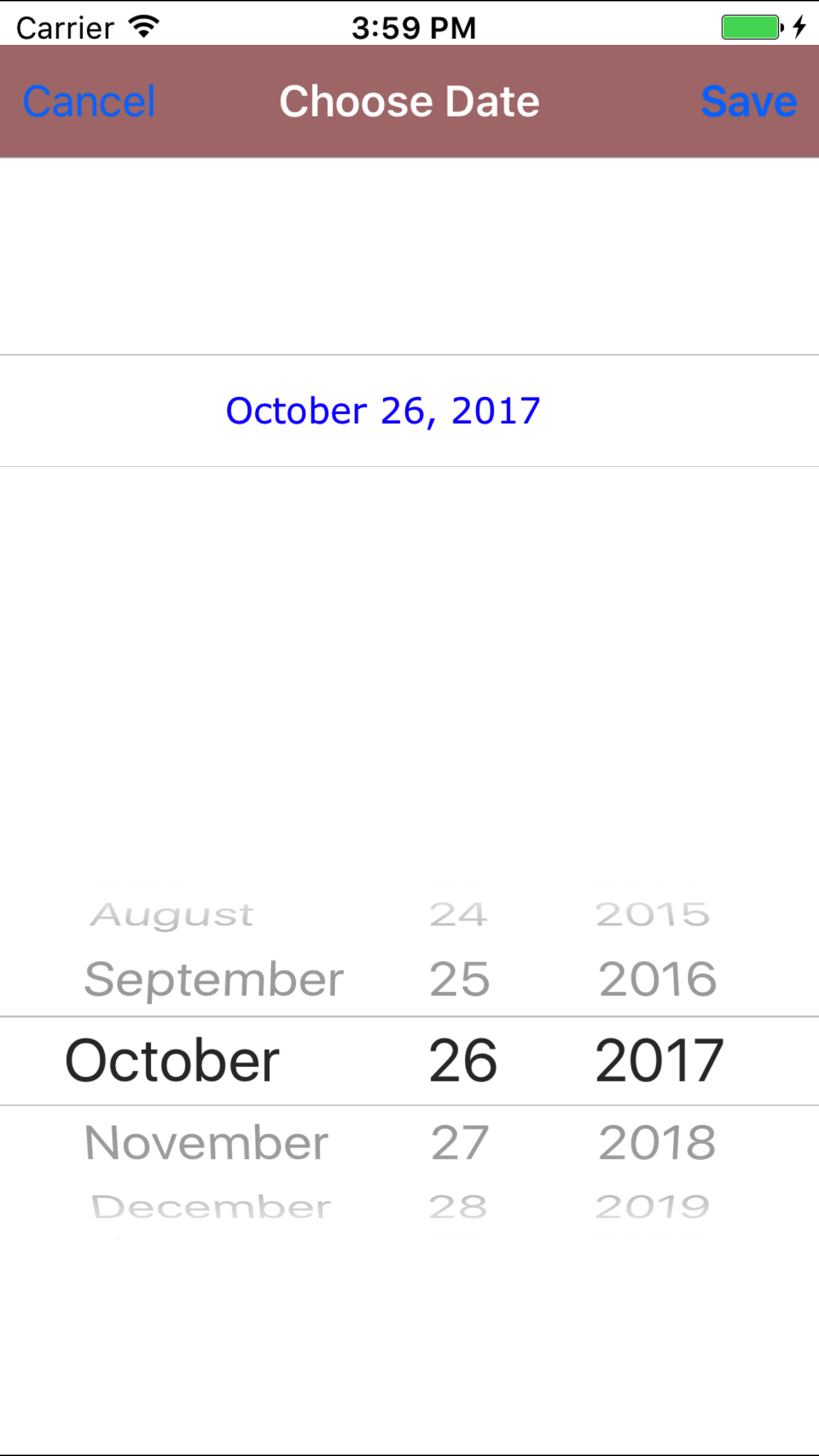

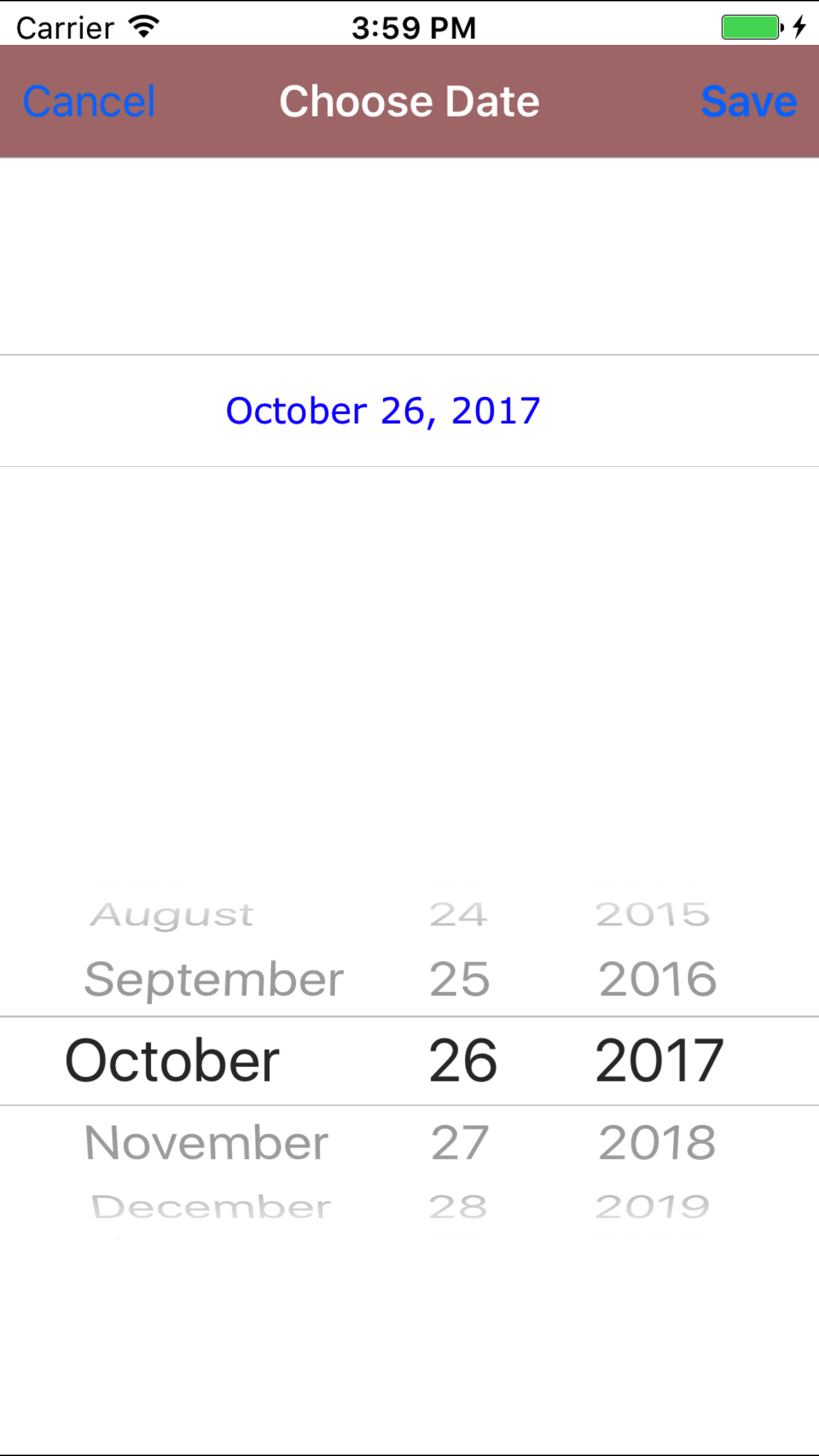

- Tap the Date field to open the Choose Date screen.

- Scroll the date wheel on the far left of the screen until the desired date is highlighted.

- Return to the Add Follow Up screen by either tapping Save in the top right corner to select the highlighted date or tapping Cancel in the top left corner to leave the Date: field unchanged.

- Follow Up Description: The Follow up Description field gives the user the ability to describe the solution to solve the problem. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the follow up

|

|

|

| Steps 1-2 |

|

|

| Step 3 |

|

|

| Steps 4-5 |

|

|

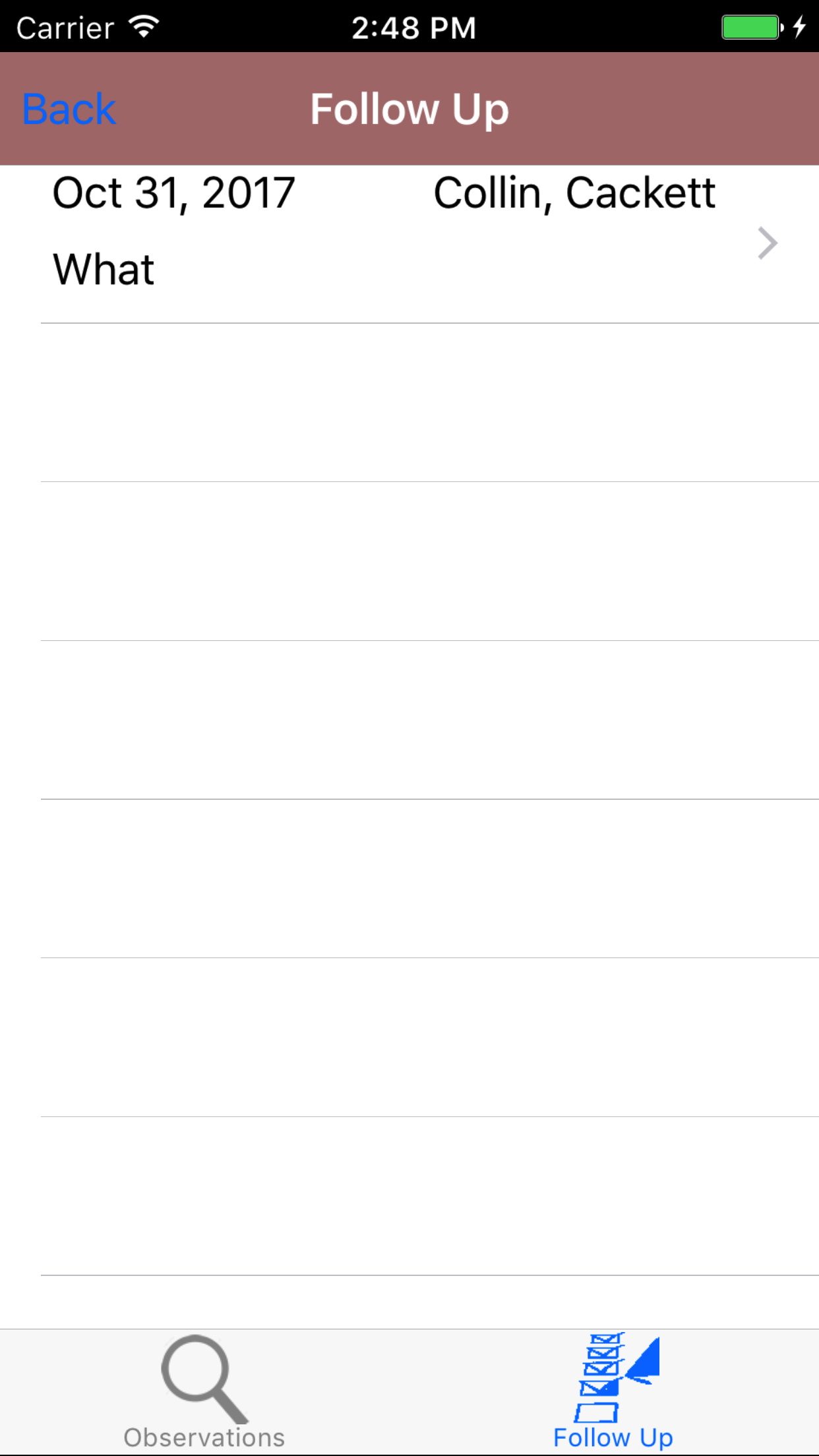

24.Look Up Follow Up |

|

Once on the Observation you would like to edit.

Steps

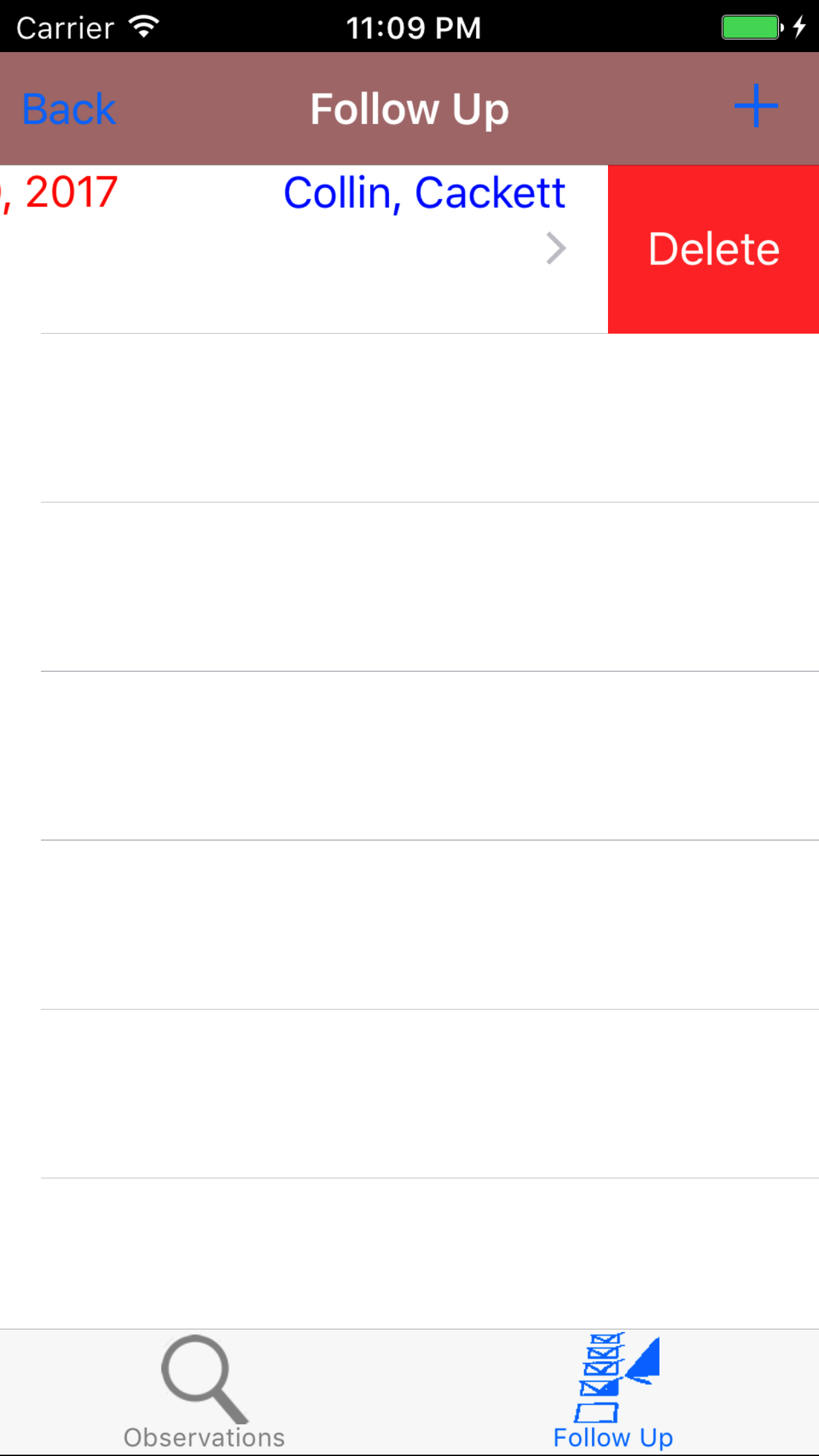

- Tap the Follow icon, the second tab. This opens the list of follows, follow up date in red text,

the employee who followed up in blue text and the description of the follow up in black text.

- Scroll the list of Follow Ups until the desired Follow Up is displayed on the screen.

- Tap on the Follow Up you would like to view. This loads the follow up edit screen.

|

|

| Steps 1-3 |

|

|

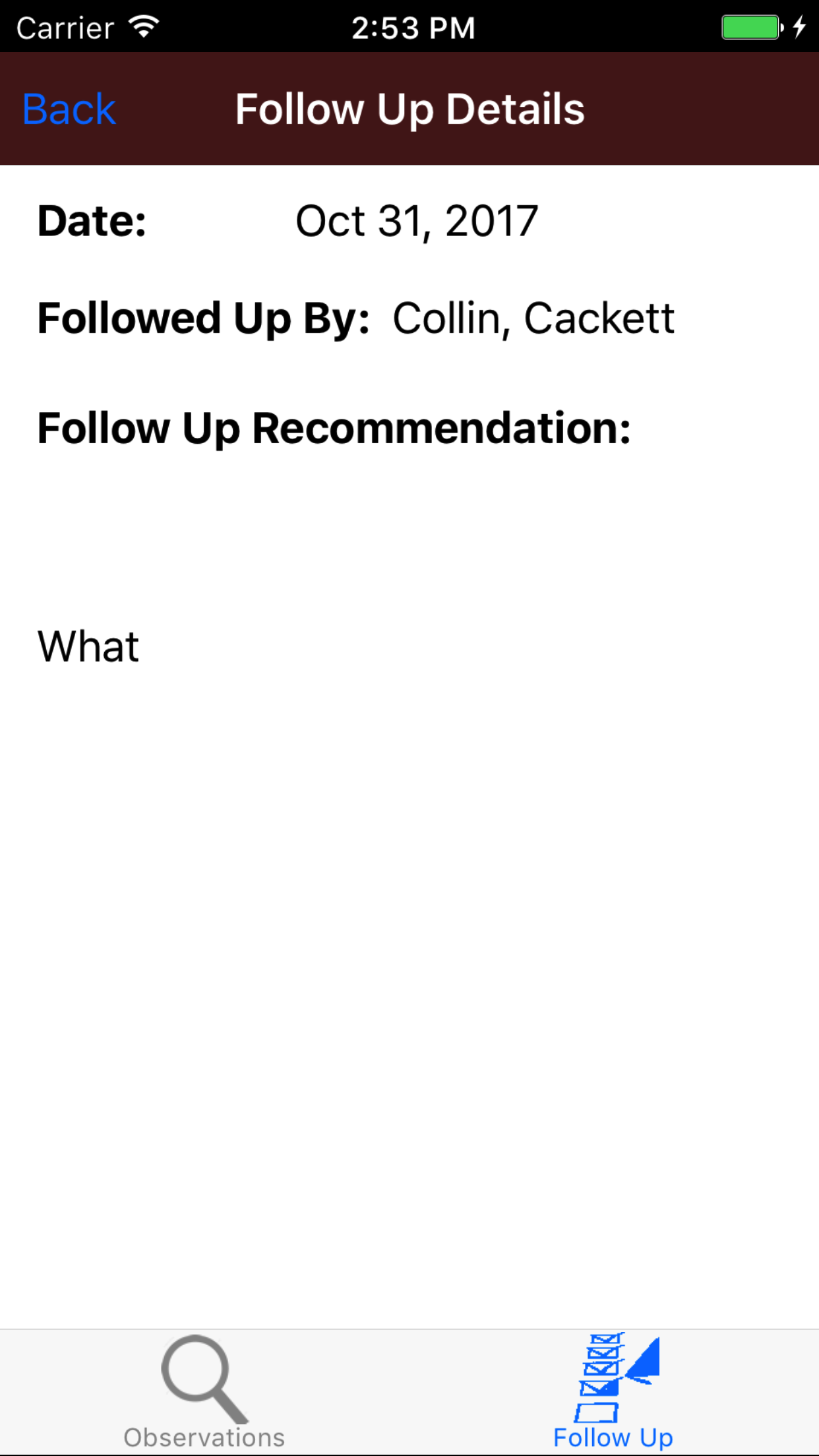

25.Edit Follow Up |

|

Once on the Follow Up edit screen

Fields

- Date: The date field allow field staff to choose the date the issue should is resolved by.

- Tap the Date field to open the Choose Date screen.

- Scroll the date wheel on the far left of the screen until the desired date is highlighted.

- Return to the Add Follow Up screen by either tapping Save in the top right corner to select the highlighted date or tapping Cancel in the top left corner to leave the Date: field unchanged.

- Follow Up Description: The Follow up Description field gives the user the ability to describe the solution to solve the problem. The character limit of this field is 250.

- Tap Save in the top right corner of the screen to save the follow up

|

|

| Step 1 |

|

|

| Steps 2-3 |

|

|

|

26.Delete Follow Up |

|

Once on the Observation you would like to edit.

Steps

- Tap the Follow icon, the second tab. This opens the list of follows, follow up date in red text,

the employee who followed up in blue text and the description of the follow up in black text.

- Scroll the list of Follow Ups until the desired Follow Up is displayed on the screen.

- Swipe from the right edge to the left to bring up the delete button for the follow up.

- Tap the Delete button. The follow up will be deleted.

|

|

| Steps 1-4 |

|

|

|

27.Submit Safety Inspection |

|

Once on the Safety Inspection you would like to Submit, on the details tab.

Steps

- Tap the Submit Safety Inspection button.

|

|

| Step 1 |

|

|

|

28.Delete Safety Inspection |

|

Once in the Safety Inspection section

Steps

- Tap the second tab on the menu, the Safety Inspection view.

- Scroll the list of Safety Inspections until the desired Safety Inspection is displayed on the screen.

Listing the safety inspection date in red text, the work order number in blue text

and the the customer name and job site in black text.

- Swipe from the right edge to the left to bring up the delete button for the safety inspection.

- Tap the Delete button. The safety inspection will be deleted.

|

|

| Steps 1-4 |

|

|

30.View Closed Safety Inspection |

|

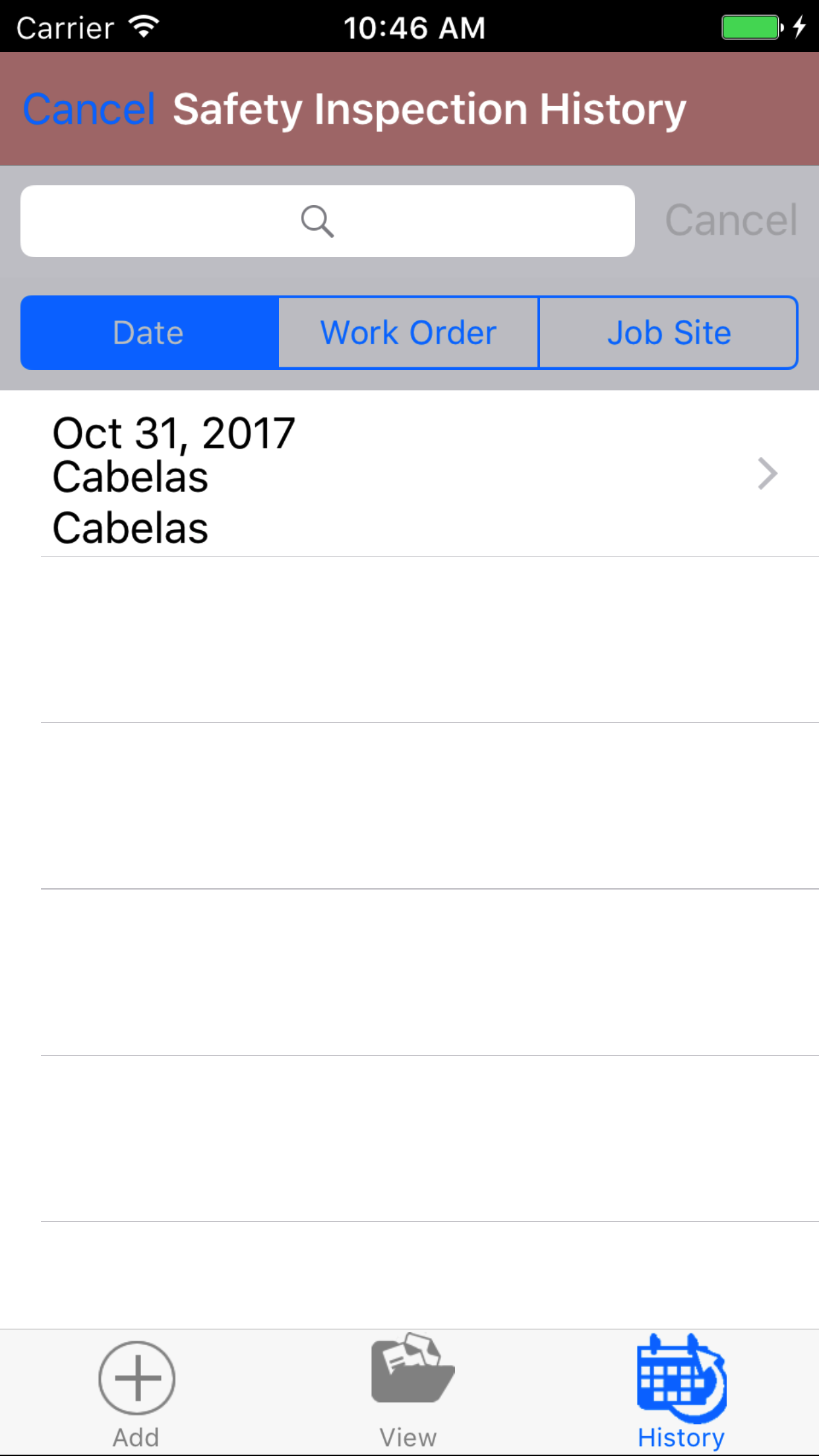

After Safety Inspections have been closed out, they will be available to look at through the History view on the iPhone Application.

Once on the Safety Inspection section

Steps

|

|

|

- Tap the third tab on the menu, the History tab of the main menu view. This loads with a list of the closed out

Safety Inspections listing the the date, work order number, customer and job site name of the Safety Inspection in black.

- Scroll the list of Safety Inspections until the desired Safety Inspection is displayed on the screen.

- Tap on the Safety Inspection you would like to view. This loads the first tab, the Safety Inspection details tab of the History view.

It loads the following details including date, customer name, scope of work, notes, signature and inspected by name.

- Tap the second tab, the Employee’s tab of the History view. This loads with the employee’s names and their signatures

of the employees assigned to the Safety Inspection.

- Tap the third tab, the Inspection Categories tab of the History view.The screen loads

with the list of the 6 checklist categories of the safety inspection. Tap on each category to view the inspection tasks.

- Tap the fourth tab, the Observation tab of the History view. This loads with the observation tab, tapping on each observation will bring up the

observation details, and the second tab on these details screen loads the follow up for those observations.

|

|

| Steps 1-2 |

|

|

|

|

|

|

| Step 5.a |

|

|

| Step 5.b |

|

|

| Step 5.c |

|

|

| Step 5.d |

|

|

|

|

|

| Step 6.b |

|

|

| Step 6.c |

|

|

| Step 6.d |

|

|

|

30.Update Safety Inspections |

|

To ensure field staff have the most up to date copy of the inspection tasks a company is

using make sure to update your phone on a regular basis. For more information about updating your phone.

Steps

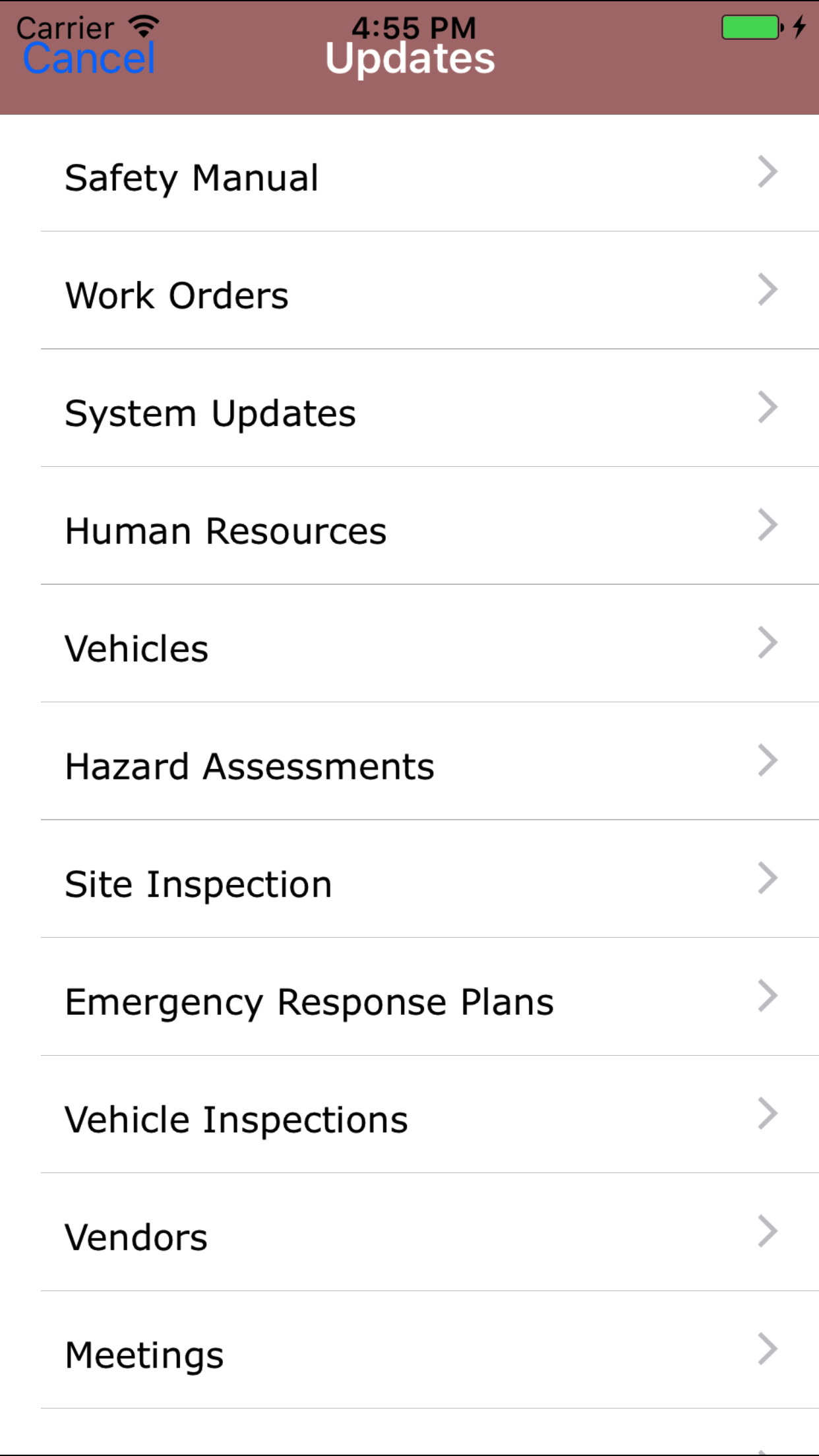

- From the Menu screen, tap the Updates button.

- Scroll the list of sections until you find the Safety Inspection button.

- Tap on the Safety Inspection button.

|

|

|

| Step 1 |

|

|

| Steps 2-3 |

|

|